+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

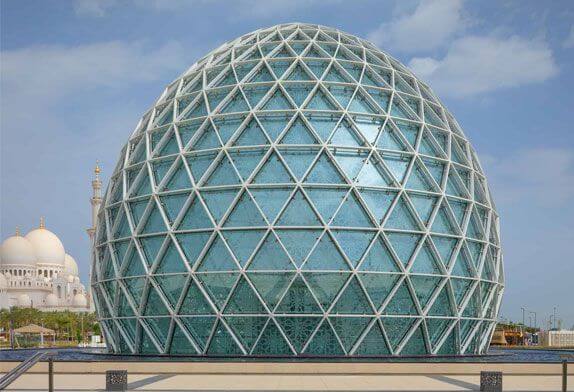

1. Glass Dome Roof Project Overview

The roof of the museum is a dome steel structure, which adopts a steel glass roof with a conical dome. The ceiling is about 16m high from the ground, the suspended ceiling material is tempered laminated glass (8+1.52PVB+8), the plane shape is an equilateral octagon, each side length 6m, and the facade is octahedral. The structure is complex, the material is fragile, the installation is difficult, and the details of the anti-leakage treatment process are complex. The glass dome construction difficulties of this project are the overall assembling and hoisting of steel structures and the installation and treatment of toughened glass. The overall design of steel structure requires a small deviation of position and size, neat installation of tempered glass to joints, and a comfortable appearance. Due to the difficulty of aerial work and the aesthetic requirements of steel structure modeling, safety and accuracy are the characteristics of aerial dome glass ceiling construction.

2. Glass Dome Building Process Principle

After the second deepening design of the steel structure dome roof, the factory finished production. Toughened laminated glass is processed in units according to design in the factory, hoisted to the dome, adjusted to the uniform gap, and fixed with a silicone glue hook.

3. Glass Dome Roof Process Flow

Measurement and routing → overall ground assembly → reinforcement of roof structure bearing → installation of steel structure dome → installation of tempered glass → glass gap gluing.

4. Operation Essentials

1) Measurement and laying out: before construction, convert the coordinates of 8 small steel columns on THE CAD drawings, set up the total station instrument on the roof, mark the position of 8 small steel columns on the roof beam accurately, check the position of steel column bolt holes, and correct the holes with deviation in time.

2) the overall ground assembly: according to the roofing datum line, the wiring, and complex ruler, check the main structure, and the error of the embedded parts, the embedded parts should be in accurate position, fixed firmly. The position of the roof beam and steel column should be released at the ratio of 1∶1 on the hardened flat site.

3) Roof structure support reinforcement: considering the various loads and reaction forces generated by the lifted members in the rising operation, the roof steel members are temporarily reinforced to ensure the safety of the members. At the same time, the safety net under the dome is checked to ensure the safety of personnel working at high altitudes.

4) Installation of steel structure glass dome roof: the steel structure dome is processed and manufactured by units in the factory after the second deepening design, and the construction site is assembled as a whole. The lifting points are set on the symmetrical 4 main beams to lift the dome into place as a whole. The toughened laminated glass is processed in blocks according to the design in the factory, hoisted to the dome, adjusted to the uniform gap, and fixed by silicone glue pointing.

5) toughened glass installation: glass according to the design of block factory processing shipped to the site, check the size (ensure that the width of the glass seam 20mm, size tolerance ±2mm) after no error, in each glass 5mm from the edge, straight paste tape, to be glued after the tear. Wipe the surface clean before hoisting, and transport it to the roof working surface in batches by crane. Before installing the glass, check all the iron parts and steel frames of the dome, and pull the double safety net within the working range under the dome. When installing, the operator should fasten the safety belt and tie it with the main steel structure. Double-sided adhesive tape should be attached to the steel beam first, and the adhesive strip should be close to the bonding surface and maintain lines with the board surface. The isolation paper of the adhesive strip should not be torn off before the glass is placed to prevent surface contamination, and the glass should be installed and fixed from bottom to top.

6) Glass gap glue: In the museum’s internal exhibition of cultural relics of the Song and Jin Dynasty, and the lower part of the Song and Jin tombs, waterproof work is particularly important.

The construction method of glass dome roof construction of steel structure dome is adopted to solve the problem of dangerous and difficult construction of single member assembling at high altitudes and avoid the situation of setting up scaffolding in a large area under the working surface for high altitude work. Compared with common construction methods, the project cost is reduced to the maximum, and good economic and social benefits are obtained.