+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

4.1.2、Safety protection technology for the assembly of part of the space frame in the hall

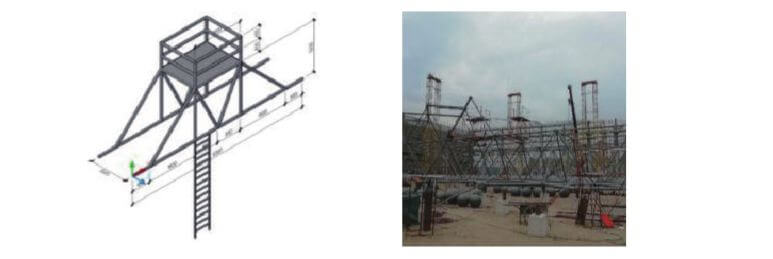

Part of the space frame in the hall is assembled at the original position (projection position). During the construction of the middle string space frame, the height of the working surface from the ground is 2.50-3.85 m, and the height of the top string space frame is 5.0-7.7 m. According to the site conditions, a temporary operating platform was designed (Figure 5). The operation platform is welded with φ48 mm×3.5 mm steel pipes, the size of the working surface of the operation frame is 1.2 m×1.6 m, the height is 2 m, and protective railings are set.

Figure 5 Inverted cone installation safety protection

The platform is moved by a crane during construction, and the two sides are bound and fixed with 8# lead wires and space frame poles during use. When the construction personnel operate the platform up and down through the ladder, they must cooperate with the vertical life rope (safety belt with self-locking device), and use the fall arrester set on the operating platform.

4.2、Safety protection technology for ground assembly of door space frame

There are 5 layers of space frames at the gate of this project, and the height of the construction work surface from the ground is 0.85-16.00 m. The ground assembly adopts the combination of two protection schemes of scaffolding and operating frame, that is, the chords of the 1st to 3rd floors are protected by scaffolding, and the 4 ~5 layers of chords are protected by operating frames.

1)、Scaffolding protection, that is, scaffolding is erected layer by layer along with the assembly process of the 1st to 3rd layers of the truss. When assembling the middle chord of the first layer, set up the first layer of scaffolding, and the scaffolding platform is 1.2 m away from the ball center of the middle string of the space frame; when assembling the second layer of middle strings, set up the second layer of scaffolding, and the scaffolding platform is 1.2 m away from the center of the upper string ball of the space frame 1.2 m; the width of the scaffold board is 1.2 m, and the edge protection should be done.

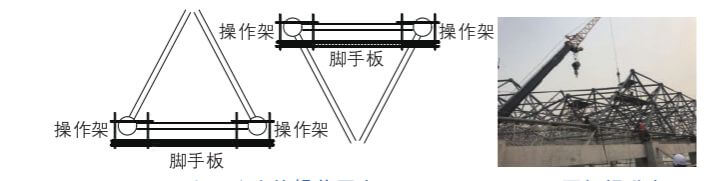

2)、Protection of the operating frame, that is, for the positions of the welding balls on the 4th to 5th layers of the space frame, the operating frame is fixed by installing rods, so as to provide safety protection for construction workers (Figure 6).

Figure 6 Schematic diagram of the space frame operating frame at the door head

4.3、Installation and protection technology of radiant heating and other supporting facilities in the space frame

After the ground assembly of the hangar space frame is completed, supporting facilities such as radiant heating pipes, lamps and trunking, siphon rainwater pipes, and maintenance horseways are installed at the same time. The operating surface is only about 1.5 m away from the ground. The risk of subsequent high-altitude installation greatly reduces the difficulty of safety protection, and also makes the prefabricated construction well applied in this project.

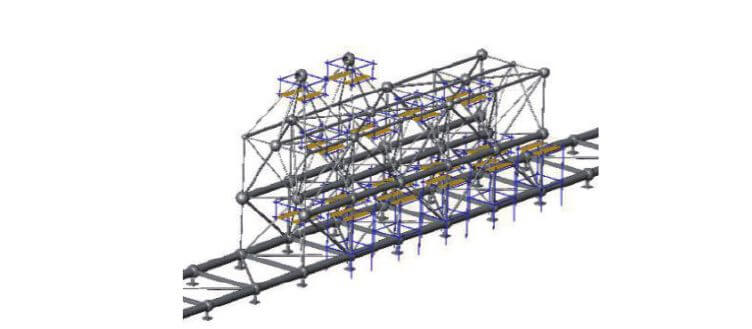

4.4、Lifting support safety protection technology

The operating frame of the lifting bracket must meet the requirements of construction protection. The operating frame is 2.35 m × 1.86 m, using φ48 mm × 3.5 mm steel pipes, and 1.2 m high body railings must be erected around it, and foot guards must be used. The vertical space frame is closed (Figure 7). The construction personnel operate the platform up and down through the ladder set on the operation frame, and the fall arrester is hung on the operation frame.

Figure 7 Lifting the stand operating frame

4.5、Safety protection technology for space frame closing parts

4.5.1、Safety protection technology for the closing part of the space frame in the hall

During the closing process of the space frame, the existing scaffolding of the civil engineering can be used to lay the scaffold board as the operation platform. Probe boards are strictly prohibited on the rod. Operators must be equipped with a vertical life rope (seat belt with self-locking device) when operating the platform up and down, and use the fall arrester set on the operating platform.

Two horizontal safety nets shall be set under the scaffolding board of the working layer.

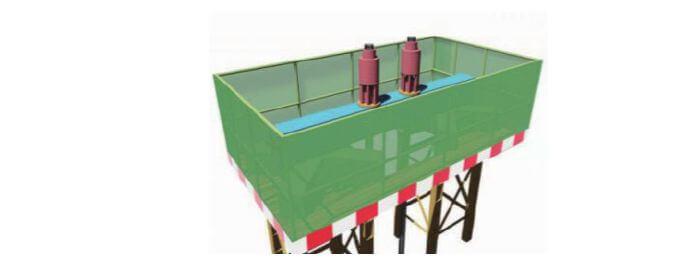

4.5.2、Safety protection technology for the closing part of the hoisting point of the space frame in the hall

A temporary operating platform (Fig. 8, Fig. 9) is used for installation of the closing rods at the lifting point of the space frame, and the operating platform is supported on the chords of the space frame. The scaffolding board is placed on the operating platform to form a safe protection channel.

Fig. 8 Operation platform for closing the upper and lower chords Fig. 9 Lifting point of space frame

Fig. 8 Operation platform for closing the upper and lower chords Fig. 9 Lifting point of space frame

4.6、Installation and protection technology of roof purlins and roof panels

4.6.1、Safety protection technology for roof purlin installation

The roof purlins are assembled on the ground and installed before lifting. The safety protection measures adopt the method of hanging double-layer horizontal large eye nets on the lower strings of the space frame, pulling the safety rope on the string ball top of the space frame, and installing wooden scaffolding boards to install the purlins in separate spans.

4.6.2、Safety protection technology for space frame roof panel installation

The installation of space frame roof panels needs to be equipped with safety poles and long safety ropes. Construction workers must wear safety belts throughout the process and use them in a standardized manner. A horizontal safety net should be set at the lower string of the space frame.

Designing corresponding safety protection measures for each link of the construction process is a major measure to improve the level of engineering safety risk management and control. In this project, corresponding safety protection schemes have been specially formulated for the assembly, lifting and closing of the hall and door head, and targeted devices have been designed to ensure the safety of on-site construction, especially those working at heights.

The space frame area of this project is about 15,000 m 2, and the lifting quality is 1,600 t. It took 4 months to complete. During the entire construction process, no casualties such as personnel falling from high altitudes occurred, and it was rated as a safe and civilized model construction site in Beijing. The use of some simple platforms not only protects the safety of operators, but also greatly shortens the construction period and produces good economic benefits.