+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1、Project overview

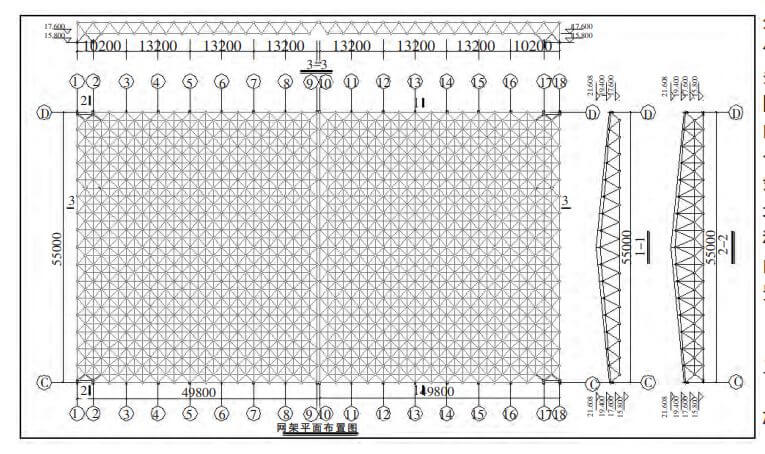

The construction area of this project is 7770.77m 2, and the main body is frame structure. The roof truss space frame is divided into 2 groups, the size is 55.2×49.5m, the bolt ball joints, the square quadrangular pyramid bolt spherical space space frame structure, the space frame size is 3.3×5.45m, the thickness is 1.8-4m, and the top is supported by 36 supports The whole roof truss. The height of the space frame is 15.8m-22.13m, the total weight is 278t, the total number of nodes is 1092, and the total number of rods is 4160.

2、Roof truss structure

The shape of the roof truss of the Dingjian factory is a herringbone roof, and the slope is found by the space frame structure and small columns. Because the space frame adopts structural slope finding, there are many types of bolt ball joints and rods in the space frame, which increases the difficulty for the processing and assembly personnel of the space frame. The space frame steel pipes are made of Q235B and Q355B steel respectively, the cone head of the sealing plate, the purlin, the support and the support are made of Q235B steel, the bolt ball is made of No. 45 steel, and the high-strength bolts are made of quenched and tempered 40Cr. The space frame structure is designed using MST2008 software.

3 、main construction methods

3.1 、Component processing bolt ball screw thread drilling, space frame rods, cone head sealing plate welding and primer are all completed in the manufacturer’s processing plant. Fireproof paint is applied on the construction site.

3.2 、Anticorrosion of finished rods

The surface of the component is derusted by sand blasting, the grade of derusting is Sa2.5. After derusting, it is qualified after inspection, and the polyurethane primer, intermediate paint and top coat are sprayed. The thickness of the dry paint film of the coating is not less than 150um for the outdoor part and not less than 125um for the indoor part., the allowable deviation of the dry paint film thickness of each coat is -5um, spray once and wait for the paint to dry, and then spray again after passing the acceptance. The quality inspection mainly checks whether the surface layer of the component is missing coating, whether there is any phenomenon of wrong coating, coating rust, peeling and so on. It is required that the coating is even and there is no phenomenon of falling, wrinkling and so on. The painted surface should be well marked and numbered.

3.3、 Component transportation

Qualified components can be packaged, marked for record, and pay attention to protect the coating film. According to the progress of the operation, choose the appropriate mode of transportation, and ship in stages, which will not affect the progress of the operation, and at the same time ensure normal delivery. After the components enter the site, they are stored according to the specifications and models, which is convenient for the assembly of the space frame.

3.4 、On-site assembly

According to the characteristics of the project and the construction period, the space frame is assembled on site in strips and blocks. After the assembly is completed, it is hoisted by three cranes. This method has the following main advantages: it can be assembled in strips on the flat space frame ground. The ground assembly of the space frame is easy to control the arching deflection, avoiding large errors during assembly, and flow operation can be carried out between each block, the assembly speed is fast, and the construction period is short.

3.4.1、 Preparations before assembly

Before assembling, check the axis dimension and elevation of the embedded parts in civil engineering, and start the installation of the space frame after it is correct. Since the space frame is supported by upper chords, the force applied to the space frame when assembled in the field is different from that after the net frame is installed. Therefore, it is necessary to check and calculate according to the form of the space frame and the ground support. After confirming that the requirements are met, the assembly can be carried out.

3.4.2 、Assembly process

Check the dimensions and specifications of the balls and rods one by one with reference to the construction drawings. According to the design requirements, assemble the lower chord, the web bar and the upper chord in sequence. Specific operation process: Assemble the lower chord unit on the ground, measure the size of the unit axis and diagonal according to the design requirements; assemble the upper chord, and support the web to stabilize the space frame. Due to the limited width of the site, each space frame is divided into two parts and assembled separately. After the space frame is hoisted to the top of the support, the docking is carried out. After the docking is completed, the space frame and the support are fixed on the pre-embedded steel plate of the column. During the assembly process, measure and adjust the diagonal size deviation of the elevation of the lower chord node by steel ruler, level and theodolite. The elevation of nodes can be measured and adjusted by the level instrument, and it is required to control the adjacent height difference within the range of ±3mm.

3.4.3、 Dimensional inspection

When the length of the strip or block space frame structure unit is not greater than 20m, the allowable deviation of the length of the splicing side shall be ±10mm. When the length of the strip or block unit is greater than 20m, the allowable deviation of the splicing side length should be ±20mm. During the assembly process, the allowable deviation of the node center offset of the small unit is 2mm, and the allowable deviation of the bending sagittal height of the rod axis is L1 (rod length)/1000, and is less than 5mm; the allowable deviation of the length of the chord in the small cone-shaped unit is ±2mm; the cone The allowable deviations of the height and the diagonal length of the chord are ±2mm and ±3mm respectively.

3.5、 space frame hoisting

Based on the structure and stress conditions of the space frame, in order to improve the economic efficiency under the premise of ensuring the quality of the work and the progress of the work, the space frame is assembled on the ground in strips and blocks, and the installation method of hoisting and continuous assembly until it is in place. The order of assembling the space frame is as follows: first, zone 1, zone 2, then zone 3, and zone 4, and assemble sequentially from the middle to both sides. Figure 1.