+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

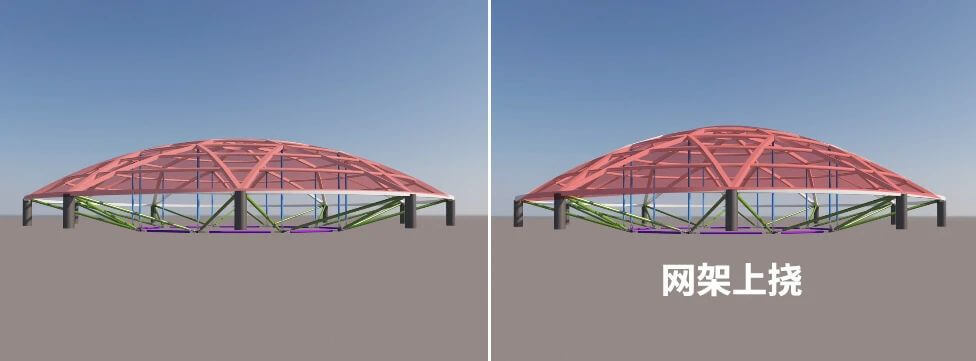

To construct a single-layer grid shell system that meets structural safety requirements, multiple factors must be considered. When designing a single-layer grid shell based on the petal profile, the cross-sectional dimensions of the members must be relatively large to ensure structural safety. This is due to the significant reaction forces at the supports of the grid shell, which necessitate additional reinforcement of the main structure. To address this, vertical struts are added below the petal beam nodes to act as supports, which reduces the span of the main beams and thereby decreases the cross-sectional dimensions of the grid shell components. Additionally, the grid shell structure includes circumferential and radial tie rods as support points, with both upper and lower nodes being hinge-connected. By adjusting the height of the struts and applying appropriate pre-stress, the structure can be fine-tuned for both shape and force, ensuring that it remains balanced under both initial and load conditions, with the lower members experiencing only axial forces.

In practice, applying pre-stress to the lower tie rods effectively reduces the outward forces generated by the grid shell. At the same time, the grid shell will experience some degree of deflection. When external forces act on the grid shell, this deflection can partially offset the downward deflection of the shell. The forces within the grid shell are transmitted through the struts, causing the tie rods to be in tension, which further reduces the impact of outward forces. This structural system is a hybrid structure that relies heavily on precise pre-stress application, accurate geometric design, and component precision.

The molding process during construction is a continuous dynamic equilibrium state that demands a high level of technical expertise from the construction team. The construction process is prone to sudden changes in component deformation, which places significant demands on the technical skills of the construction team. Every detail in the construction process must be handled with care to ensure stability throughout the entire construction phase.

In summary, designing and constructing a single-layer grid shell structure requires a comprehensive consideration of member cross-sections, support reaction forces, and the arrangement of struts. Through precise design and construction, the safety and stability of the structure can be effectively ensured. However, this process places high demands on the technical capabilities and experience of the construction team, requiring strict control of every aspect during construction to prevent component deformation or structural imbalance issues.