+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1 Support node deepening design

Space frame is generally resting on the top of columns, beams and other lower support structure, the support node refers to the support structure of the space frame node. The deepening design of the network frame begins with the support node, the elevation and position of the support node determines whether the construction of the network frame can be carried out normally.

The deepening of the support node needs to pay attention to the following points:

(1) The elevation of the top surface of the lower concrete structure or steel structure and the position of the embedded parts should be accurate.

(2) The form of bearing nodes need to be determined, common rubber plate bearing, basin type bearing, should pay attention to the direction of the bearing constraints.

(3) side bearing node is often close to the daughter wall, need to pay attention to the bearing node and the net distance between the daughter wall, generally keep more than 50mm.

(4) middle bearing large, often larger size of the base plate, need to pay attention to the lower concrete column or steel column section to meet the requirements, do not meet the requirements of the case need to expand the column head node.

(5) the top string support type space frame, support position rod is often easy to collide with the lower support structure need to pay attention to review, support ball node bottom to support the distance between the base plate should meet the slanting web and columns or beams do not collide with the requirements.

(6) the outer side of the space frame support need to take limit measures.

2 Ball node deepening design

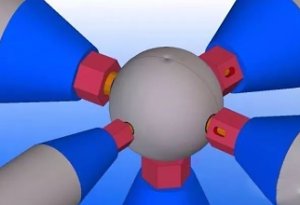

Bolted ball node model

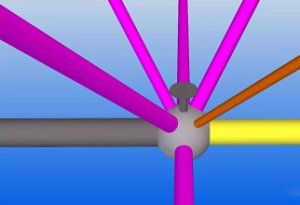

Welded ball node model

Space frame ball node form is divided into welding ball and bolt ball two kinds, bolt ball using high strength bolt fastening connection, welding ball is used in the field weld connection.

Ball node design deepening attention to the following points:

(1) Bolted ball node fittings vary among manufacturers, and the fittings data should be obtained before deepening.

(2) Bolted ball nodes in the steel ball, high strength bolts, sleeves, fastening screws, cone head or sealing plate materials should be in line with the design and specification requirements.

(3) The grade of high-strength bolts in bolted ball nodes shall be selected according to specifications.

(4) The diameter of the bolt ball should ensure that adjacent bolts do not touch each other in the ball and should meet the requirements of the sleeve contact surface.

(5) Bolt ball node in the rod end of the cone head or sealing plate using welded connections, connection weld bearing capacity should not be lower than the connection of the steel pipe; cone head cross-section and sealing plate thickness should be calculated according to the actual size of the force to determine.

(6) The welded ball is generally a hollow ball welded by two hemispheres, and it is necessary to determine whether or not to set up stiffening ribs according to the size of the force.

(7) welded ball outside diameter and wall thickness ratio, ball outside diameter and the main steel pipe outside diameter ratio, the ball wall thickness and the main steel pipe wall thickness ratio needs to meet the specification: the ball outside diameter and wall thickness ratio should be taken 25 ~ 45, the ball outside diameter and the main steel pipe outside diameter ratio should be taken 2.4 ~ 3.0, the ball wall thickness and the main steel pipe wall thickness ratio should be taken 1.5 ~ 2.0 and the ball wall thickness should not be less than 4mm.

(8) Welding ball and steel pipe connection should be beveled weld, steel pipe and the ball should be left between the gap to ensure that the weld penetration to reach and steel pipe and other strong.

(9) welded ball nodes connecting the number of rods, in order to reduce the diameter of the ball allows some of the rods to converge, but should comply with the specification requirements of the structure: the axis of all converging rods must be passed through the ball centerline; two rods converge, the cross-sectional area of large rods must be welded to the ball in full cross-section (two rods cross-section is equal to take the tensile rods), and another rod bevel welded in the phase of the intersection of the rod, but should ensure that there is a 3/4 cross-section welded on the ball! The other bar is beveled and welded on the intersecting bar, but it should be guaranteed that 3/4 section is welded on the ball, and the stiffening ribs should be set up according to the requirements; for the bar with large force, the supporting plate can be set up according to the requirements.

3 Support node deepening design

Support node is the link between the space frame structure and the enclosure structure, often arranged in the space frame chord and side.

The deepening design of support node needs to pay attention to the following points:

(1) Under the premise of meeting the force requirements, the support and ball connection try to use high strength bolts to reduce the amount of overhead welding.

(2) The top plate of the support should be set into a circle to ensure that the support can be rotated 360 degrees along the axis of the rod can be positioned and installed.

(3) When the height of the support is large, it is better to set up inclined support to ensure the lateral stability of the support.

4 Purlin gutter enclosure system deepening design

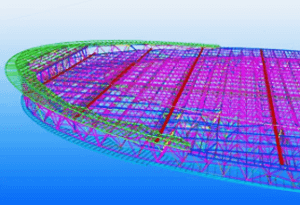

Roof purlin gutter enclosure system deepening modeling

The space frame purlin enclosure system often adopts the form of main and secondary purlin connection, the main purlin often adopts I-beam and rectangular tube section, and the secondary purlin often adopts C-type section.

The deepening design of purlin enclosure system needs to pay attention to the following points:

(1) The main purlin and support, main purlin and secondary purlin connection should adopt bolt connection.

(2) When rectangular tube section is used, attention should be paid to purlin end blocking to avoid rusting due to internal inconvenience of anticorrosion treatment.

The space frame structure has various forms, can present various shapes of building plan, and the building shape is light and beautiful, the sense of space is sufficient at the same time can meet the large span requirements with low steel consumption, so it is widely used in stations, airports, exhibition halls and other large buildings. The deepening design of space frame structure is different from other steel structure types, which needs to be completed by combining different software such as Tekla, 3D3S, MST, etc. The designers are required to be more comprehensive and able to utilize different tools and software to deepen the design of each detail in a seamless way.