+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

2.4、Space frame installation features and precautions

(1) The construction feature of the starting space frame is to rotate the supporting top chord ball in the column top support, so as to start in pieces, one end of the space frame with the supporting top chord ball as the axis, the other end can rotate up and down under the action of the crane,until it is lifted to the design elevation position for assembling. When assembling No.1 space frame,first fix the upper chord ball bearing on the pre-buried bolts of the support column according to the axial position, and then put the upper chord ball of the support point directly in the bearing (to be welded after the starting frame is assembled together), so that the ball can be rotated in the bearing. The upper chord ball on the upper chord bearing as the support rotation point,first put together a few sections of the space frame, then use the 25T crane to lift the end and then put down a few sections, shift the crane forward and then lift and then put together again,and so on, put together the space frame forward until the completion of the lifting area.

(2) In order to prevent the deformation of the space frame, it is necessary to set two ¢16mm steel wire ropes and hand chain hoist (5 tons) at the lower chord ball (the first lower chord ball from the support) to prevent the deformation of the space frame, and the tightness of the steel wire rope is appropriate to the arc of the space frame for the design size. The lifting point is chosen at the lower chord ball.

(3) According to the area required for the start on the ground for assembly, the construction of the start space frame is characterized by the rotation of the start space frame supporting upper chord ball in the column top support,so that one end of the block start space frame to support the upper chord ball as the axis of the other end in the crane upward traction role of the rotation of lifting, until lifting to the design elevation position for assembly.

(4) When assembling the other side of the 42.5m span space frame,set up the wire ropes in the same way (two wire ropes from the first lower chord ball to the 11th lower chord ball from the support). 42.5m span space frame span out of the support assembly,set up two lattice type temporary supports in the 42.5m span space frame,and fix them with the cable wind rope.

(5) After the completion of the space frame docking,immediately weld the welded ball and support at the fixed support body, respectively,with two cranes back to both sides of the bulk, when installing,starting from the support body at the first installation to the next support body at the vertebrae,and then from the installed support body at the extended space frame curvature direction into parallel to the direction of the bulk,until the installation to support body fixed,and then round-trip construction,until the space frame installation is complete.

(6) This project has an expansion joint in the space frame,and when the space frame is installed to the location of the expansion joint,it is immediately followed by the installation of the space frame at the expansion joint,and if one side of the space frame continues to be installed using the lifting method,it will affect the overall schedule of installation.

(7) Purlin installation is the key process of enclosure color board installation, the quality of which directly affects the flatness,beauty and connection strength of the color board and must be paid full attention to. Check the size,quantity and appearance quality of the material to ensure the construction needs.

(8) The installation direction of the color plate installation should consider two factors:one is the dominant wind direction of the area where the project is located all year round, and the other is aesthetic. In the absence of special requirements, the installation direction of the roof panel should be opposite to the dominant wind direction.

(9) Due to the high height of the project, the slope is large, the roof basically can not stand people,in the construction of the safety of personnel should be the first,the construction of machinery and equipment used and work equipment must be checked to ensure that the use of machinery and other intact. Personnel should use soft ladders when installing and fastening roof panels on the roof,and the construction personnel should set up double insurance,one is to set up safety nets at the bottom and outside of the space frame,and hang safety nets on the space frame directly below the operator,and the second is that the safety belt of the installation personnel must be worn correctly.

Summary of this coal shed construction:

(1) The inner side of the coal retaining wall is made into a flat type,and no facilities are installed on the inner side to avoid touching the columns and facilities when cleaning the accumulated coal.

Figure 5 Comparison of coal retaining wall column layout

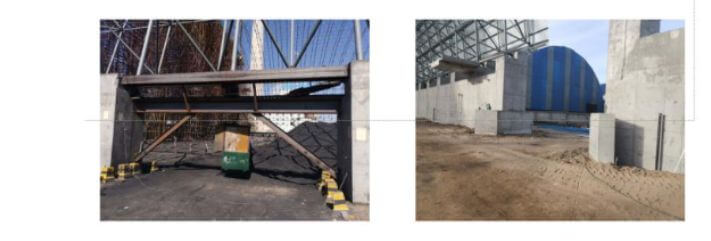

(1) Installation of anti-collision wall in the doorway area.

Figure 6 Comparison of doorway crash wall

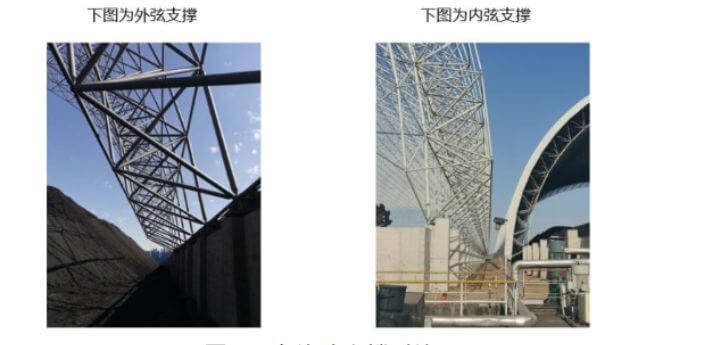

(2) Adopting inner chord support can increase the volume of enclosed area, and at the same time,it can avoid the mechanical collision of steel structure when stacking and taking coal operation in coal storage yard.

Figure 7 Comparison of inner and outer string support