+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The processing of steel pipe is divided into cold forming and hot processing, according to the type of seamless steel pipe and straight seam steel pipe.

1. Section requirements of round steel pipe diameter and wall thickness ratio should not exceed 100 (235/fy); at the same time need to meet the requirements of the diameter-thickness ratio, compression bending member of the diameter-thickness ratio of not less than the S2 level; at the same time need to meet the requirements of the length of the thin ratio of the length of the compression rod is not greater than 150, the length of the thin ratio of the tensile rod is not greater than 400;

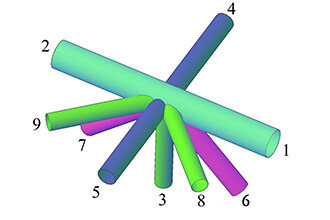

2. Coherent node requirements

(1) the external size of the main pipe should not be smaller than the external size of the branch pipe, the wall thickness of the main pipe should not be smaller than the wall thickness of the branch pipe, in the branch pipe and the main pipe shall not be inserted into the main pipe at the connection of the branch pipe.

(2) The angle between the main pipe and the branch pipe or the branch pipe axis should not be less than 30°.

(3) It is desirable to avoid eccentricity at the connection node of the branch pipe and main pipe;

(4) The end of the branch pipe shall be cut by an automatic pipe-cutting machine, and the branch pipe may not beveled when the wall thickness is less than 6mm.

(5) branch pipe and the main connection weld, in addition to the branch pipe lap should be consistent with the provisions of Article 13.2.2 of this standard, and should be continuously welded along the entire circumference and smooth transition; weld form can be used along the entire circumference of the fillet weld, or part of the use of butt weld, part of the use of angle weld, of which the angle between the branch pipe wall and the wall of the main pipe is greater than or equal to the 120 ° of the region is appropriate for the use of butt weld or fillet weld with beveling; fillet welding foot size should not be greater than 2 times the branch pipe wall thickness; lap branch pipe periphery can not be beveled. Angle weld foot size should exceed the branch pipe wall thickness of 2 times; lap branch pipe perimeter weld should be 2 times the branch pipe wall thickness.

(6) In the main pipe surface welding adjacent branch pipe gap should not be less than the sum of the two branch pipe wall thickness.