+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

In recent years, with the construction of the national new dry method production line in full swing. The steel space frame roof structure is more and more recognized by the majority of owners due to its short construction period and relatively high-cost performance in long-span structures. However, with the continuous expansion of the market demand for steel space frames, their prices have risen, the market competition has intensified, and various problems have been continuously exposed.

1 Consideration of the ash load on the roof area

According to the requirements of GB50009-2001 of the “Building Structure Load Code”, the ash load on the roof area of the workshop with ash source (kiln room, mill, combined storage, drying room, crushing room) should be included in the calculation.

(1) When the roof slope α<25° (such as a space frame with a flat structure), the dust load is 1kN/m2;

(2) When the slope of the roof is 25°<α<45° (steel space frames in the shape of ball castles, steel space frames with arched cross-sections, and other parts within this range) the dust load is 0.5~ according to the interpolation method Calculated value between 1.0kN/m2;

(3) Only when the slope of the roof is α>45° (for example, the steel space frame with a ball castle shape, and the steel space frame with an arched section with a slope within this range) can not consider the dust load.

Considering that most owners will not carry out regular dust removal measures on the roof, in the design of the roof space frame structure in the cement industry, the consideration of the dust load is quite strict. At present, many steel structure enterprises engaged in civil use and rarely involved in the cement industry tend to ignore or even ignore the influence of dust load when designing the space frame roof of cement plants. After combining the loads in this way, the self-weight of the designed structure will naturally be reduced. However, this will inevitably bury quality and safety hazards in the actual use process.

2. Consideration of wind load on space frame long storage yard and influence of wind tunnel effect

The most reliable data of structural wind loads are often obtained from experimental measurements, especially wind tunnel tests are the main research means, and the use of full-scale models for on-site measurement research can predict the wind loads of similar structures that are completely replicated by it under the same conditions Happening. In 2004, scholar Guo Wandong conducted a numerical simulation study on the wind pressure distribution on the surface of the greenhouse using the CFD method. In the design of industrial buildings, the influence of wind load on the greenhouse structure is often ignored, and even the dynamic effect of wind load on the greenhouse structure is ignored. The national standard “Design Loads of Greenhouse Structures” issued by my country in 2002 also did not consider the impact of wind vibration on greenhouse structures. This situation directly leads to the current engineering design only based on experience or reference to civil building codes, without considering some characteristics of greenhouses and long arch structures. According to the current domestic experimental research results, when considering the coupling effect, the wind pressure on the surface of the structure generally does not consider the factor that the wind pressure value has a large change during the coupling effect (where the wind pressure on the windward side decreases and the wind suction on the leeward side increases). , but for the fluid-solid coupling effect of the elongated storage yard space frame structure of the cement plant, the pressure difference between the fluctuating wind pressure and the average wind pressure is large, so when calculating the structural wind pressure, the wind vibration effect on the structure It should be considered, especially in coastal areas and areas with relatively high basic wind pressure. However, at present, some steel structure space frame manufacturing and design companies basically ignore the wind tunnel effect and wind vibration effect caused by the above wind loads and hide structural hidden dangers.

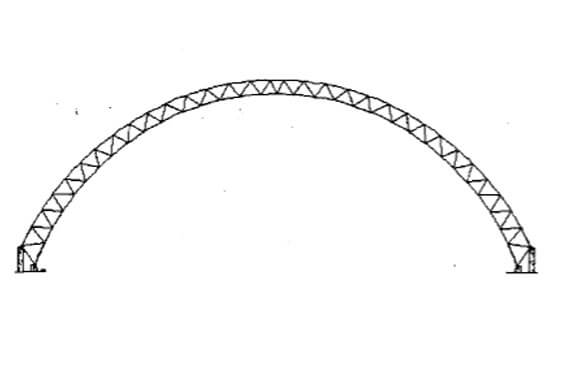

When designing the long arched  of the cement plant, we adopted the following three methods to deal with the influence of wind load on the structure. (1) The foundation is equipped with upper and lower chord double-row supports to strengthen the restraint of the supports on the space frame, as shown in Figure 1; (2) Seal the eaves on the two gable walls of the yard to greatly reduce the adverse effects of wind tunnel effects; (3) It is forbidden to randomly evacuate the bolt balls during the construction of the space frame structure in the long yard.

of the cement plant, we adopted the following three methods to deal with the influence of wind load on the structure. (1) The foundation is equipped with upper and lower chord double-row supports to strengthen the restraint of the supports on the space frame, as shown in Figure 1; (2) Seal the eaves on the two gable walls of the yard to greatly reduce the adverse effects of wind tunnel effects; (3) It is forbidden to randomly evacuate the bolt balls during the construction of the space frame structure in the long yard.

3 The height of the concrete foundation of the round castle space frame

For a space frame structure in the shape of a round pile ball castle (such as a circular limestone pre-homogenized storage yard in a cement plant), the foundation support of the space frame structure has a horizontal thrust on the concrete foundation, and the stacker-reclaimer equipment in the storage yard exerts a horizontal thrust on the concrete foundation. The curvature of the round castle space frame is limited. Based on this factor, some designers are used to making the concrete foundation top more than 5.00m to meet the equipment requirements. After further calculation, the concrete foundation can be lowered below the 2.00m elevation, and the upper part can be made into a space frame structure. This treatment can not only meet the use requirements but also improve the overturning resistance of the concrete foundation and reduce the workload of the concrete foundation by more than 30%. This approach has been applied in many cement projects.

4 Regular maintenance of steel space frame structure

The raw material storage yard of the cement plant, especially the raw coal storage yard, contains a high proportion of sulfur and is highly corrosive to the steel structure. Therefore, attention must be paid to the corrosion protection of the steel structure surface before and after the steel space frame in the raw coal storage yard is put into use. Work. Before the anticorrosion work, the surface should be cleaned to ensure a reliable connection between the paint and the surface of the steel space frame. It is recommended that the cement plant conduct an inspection every three years, and carry out anti-corrosion protection for the parts that have already been corroded. The steel structure construction unit should also take the initiative to carry out regular project quality return visits and strengthen the anti-corrosion inspection and treatment of the steel space frame.

While the steel space frame structure is being used more and more widely in the cement industry, as a designer and manufacturers, we must always pay attention to various quality problems in the design and construction process. As the owner, when bidding, one should not lower the cost one-sidedly.