+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

With the advancement of construction technology and the development of economic construction, more and more long-span and special-shaped structures are applied to large public buildings and industrial buildings. In order to meet the requirements of building function and structural safety , such buildings generally adopt spatial structural systems such as pipe trusses, string beams, and space frames. For space frame installation, there are usually 7 construction methods: high-altitude bulk method, strip or block installation method, high-altitude sliding method, overall hoisting method, overall lifting method, overall jacking method, and folding and unfolding overall lifting method. Among these 7 construction methods, except for the overall hoisting method, the overall lifting method, and the overall jacking method, the most commonly used installation methods are the high-altitude bulk method and the strip or block installation method, and support is required for such construction methods shelf. Due to the large spacing between the vertical and horizontal columns of the network frame, there are problems such as large support frame volume and low construction efficiency during the construction process. Aiming at such problems, this paper proposes a rigid support frame construction technology, which fundamentally changes the commonly used continuous support method by utilizing the rigidity of the space frame itself. At the same time, the rigid support frame has obvious advantages in terms of site occupation and support frame volume compared with other commonly used support frames, and is suitable for the installation of large-span space frame projects.

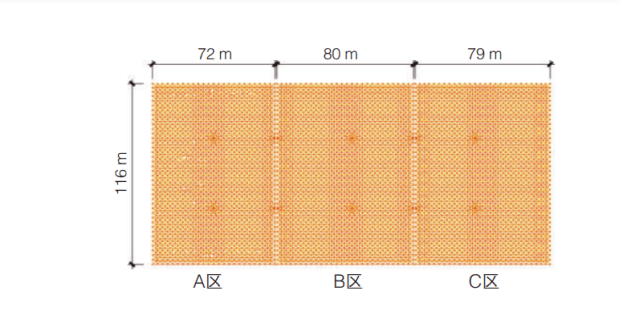

Hunan Tobacco Leaf Rebaking Co., Ltd. Chenzhou Rebaking Factory Re-baking Factory Re-location Technical Transformation Project, the roof space frame of the main workshop is a square square pyramidal bolt ball single-layer plane space frame, and the space frame plane is divided into A, B, and C areas (Figure 1). The total area of the three areas is 27069m 2 ; the distance between space frame columns is 9.00m, the maximum partition span is 45m, and the space frame size is 3m×3m. The form of slope finding is structural slope finding, with a thickness of 2.5-4.8m. The total mass of the space frame frame is about 1786t, the design steel content is 65kg/m 2 , and the local maximum steel content is 150kg/m 2 .

space frame layout

This project is a large-span space frame structure with a maximum column space frame size of 45m×45m. The methods often used in construction are piece-by-piece hoisting or high-altitude bulk construction. The supporting frames include full-wall scaffolding and sliding support frames. The construction method to be adopted in the project is a support method completely different from the above-mentioned support, that is, rigid support. Rigid support has two meanings, one is that the rigidity of the support frame itself is high; the other is that the support frame is rigidly connected to the lower chord of the network frame, making it integrated with the network frame.

2.1 Comprehensive comparison of construction technologies

2.1.1 Comparison of construction period

The construction period of the full hall scaffolding is 35 days, the construction period of the sliding operation frame is 51 days, and the construction period of the rigid support frame is 12 days. It can be seen that the construction period is the shortest when the rigid support frame is used, which is 23d faster than the full scaffolding and 39d faster than the sliding operation frame.

2.1.2 Quality comparison

Using different construction techniques, the quality standards, construction process quality control, and inspection methods for space frame installation are the same, and there is no obvious quality difference for space frame installation itself. The construction of full house scaffolding or sliding support frame is carried out on the operation platform; the construction of rigid support frame is carried out on the ground except for high-altitude bulk. Relatively speaking, the construction quality of rigid support frame is easier to obtain. ensure.

2.1.3 Cost Comparison

The project cost is relatively high when scaffolding is used, which costs about 1.8 million yuan; when using sliding support frames, it takes about 1.2 million yuan; when using rigid support frames, it costs 300,000 yuan. In terms of cost, it is more economical to use a rigid support frame for installation, which can save the direct cost of construction.