+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1 Project Overview

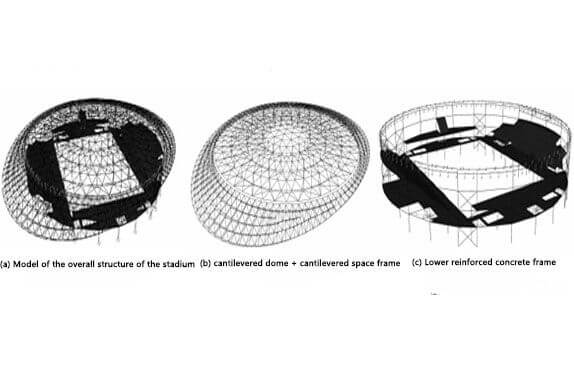

The suspended dome structure is a new type of mixed space structure proposed by Professor Mamoru Kawaguchi of the Japan University of Political Science and Law in 1993. It has been applied in large venues such as the Beijing University of Technology Gymnasium and Jinan Olympic Sports Center Gymnasium. The structure of the gymnasium introduced in this paper is divided into three parts: the lower reinforced concrete frame structure, the upper roof steel structure, and the external cantilevered space frame structure. The main roof adopts the long-span prestressed string-supported dome structure, and the cantilevered steel canopy adopts the double-layer space frame structure. The suspend-dome roof is supported on the outer concrete frame column or rigid ring beam. The overall structural model of the stadium is shown in Figure 1.

FIG. 1 Overall structure model of the gymnasium

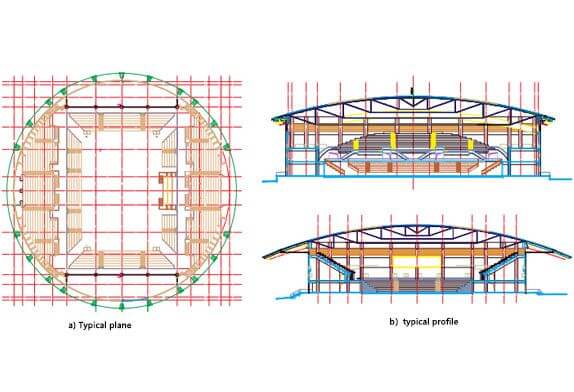

The middle part of the steel gymnasium is the sports field, surrounded by stands or functional auxiliary rooms. The roof is made of steel structure. The building plan and section of the gymnasium are shown in Figure 2. The building plane is circular, with a diameter of 75m, the plane size of the sports field is 38m × 53m, the surrounding stands, and auxiliary rooms are 3 floors, and the floor heights are 4.0m, 3.9m, and 9.2m respectively. An inter-story beam is set between the three-story frames to strengthen the integrity of the structure. The steel roof is supported on the lower reinforced concrete frame column or ring beam, and the top elevation of the frame column is 17.027m. This paper mainly introduces the steel structure design of the long-span string-supported dome steel roof.

FIG. 2 Stadium building plan and section

2 Roof structure layout

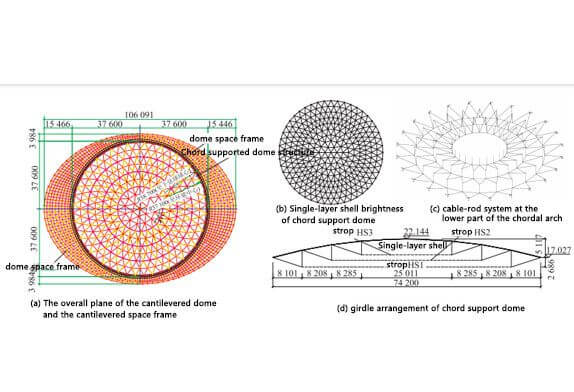

The steel roof of the suspended dome is composed of a single-layer circular reticulated shell on the upper chord, a ring cable on the lower chord, radial tie rods and vertical struts, etc., as shown in Figure 3. The span of the steel roof is 74.20m, the vector height is 5.12m, the vector span ratio is 1/14.5, and the projected area is 4321.93m2. The upper single-layer reticulated shell is composed of 8 rings of circumferential rods and 9 radial rods. The rods are all made of seamless steel pipes, which are made of Q235B steel. The reticulated shell nodes are all welded ball joints, and the reticulated shell nodes are rigidly connected. The lower chord is composed of 3-ring cables, 3-ring radial pull rods, and compression struts, etc. The ring cables are made of high-strength steel wire bundles, and the standard tensile strength is 1670MPa. The radial pull rod adopts an S850 high-strength alloy steel rod with a yield strength of 850MPa. The vertical pole is made of a seamless steel tube and made of Q235B steel. The whole structure is connected together by circular hoop cable to form a complete spatial structure system. The reinforced concrete frame column spacing of the supporting steel roof is 8.6m ~ 9.3m, the frame column is cylindrical, the column diameter is 1.0m, and the ring beam section size is 1000mm×2000mm.

FIG. 3 Structural layout of steel roof with suspend-dome

When the roof steel structure is initially built, the structure is deformed upward by applying pre-tension to the ring cable, and the support is subjected to a certain radial tension; when the structure is subjected to external loads, the overall force of the structure produces the thrust to the support. However, due to the existence of the ring cable, the lateral thrust of the entire structure to the lower-end restraining ring beam is greatly reduced, so the mid-span deflection of the structure can be greatly reduced; Due to the existence of struts, the vertical displacement and deformation of the upper reticulated shell are reduced, and the stable bearing capacity of the structure is greatly improved.