+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

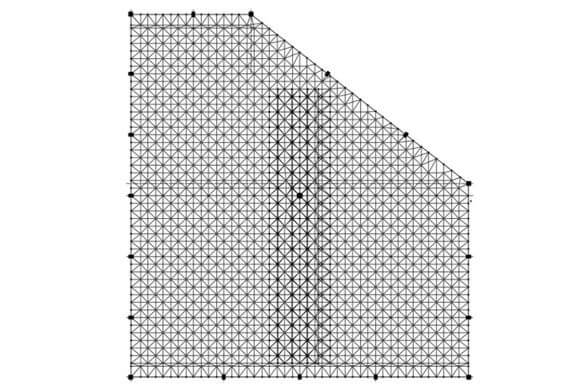

The longest side of the coal storage yard in the north-south direction is 130m, the short side is 66m, and the width in the east-west direction is 105m. Coal retaining walls are set around, the height of the retaining wall is 3m, and the clean coal storage capacity is about 40,000 tons.

There are three main types of coal storage yards in China’s current coal industry. These three forms are open coal yards, silo coal yard,s and spherical coal yards. Among them, silo and spherical coal yards are closed coal storage yards and meet environmental protection requirements. However, in the traditional open coal yard, the coal is exposed outdoors, which will not only lead to the loss of coal but also lead to the pollution of the surrounding environment. In order to improve the efficiency of coal yard storage and transportation, avoid environmental damage, and protect the surrounding environment, it is necessary to the open coal yard shall be fully enclosed in design and construction renovation.

The construction of an open coal yard is relatively simple. Generally, the soil layer is excavated to 1m, and compacted gravel is laid on the excavated part. Finally, 0.3m of compacted coal gangue is laid on the surface of the site to be used. It has the advantages of low construction cost, short construction period, and fast heat dissipation of coal, but has many disadvantages, such as coal is greatly affected by natural factors, which makes it difficult to control the water content of coal and causes serious environmental pollution.

Silos Coal silos (also called circular silos) are usually reinforced concrete structures with conical roofs, cylindrical silo shells, and inverted conical bottoms.

The spherical coal yard (also known as hemispherical coal storage bunker) generally has a spherical reticulated shell structure on the top and a reinforced concrete structure on the lower part. The diameter is often 80m-120m, and the stacking height can reach 30m. The reserves of a single spherical coal yard can reach up to 200,000. Ton. The spherical coal yard is also a fully enclosed coal yard, but the construction investment is large and the construction period is long.

This project belongs to a traditional open coal yard, which requires a closed design and construction of the original coal storage yard according to local conditions. The coal yard is not close to the railway, but its north site is close to the railway and meets the conditions for loading by the loader. Only car transportation can be used. According to the national policy, when the use of car transportation is gradually increased, the north side site can be used to realize the direct loading and outbound transportation of related by-products. The red arrow area is the reconstruction area of the project, as shown in Figure 1.

FIG.1 Coal Yard

A coal storage yard is an applied building type of spatial structure. In order to select the optimal spatial structure, the following requirements must be considered and comprehensively considered:

1) Meet the requirements of coal storage yard building functions

The architectural function of the coal storage yard is the original intention of designing the coal storage yard. Therefore, the functional requirements of the coal storage yard must be considered in the design, not only the ventilation and lighting of the coal storage yard but also the building shape and other factors. These factors all have an impact on the selection of the structure from a certain point of view.

2) Meet the requirements of coal storage yard structural safety

Coal storage yards of different structural types have different bearing capacities, so the basic parameters such as load size, structural support method, maximum span, boundary form, and final building shape suitable for each type of structure will be different. Under the safety premise of satisfying the bearing capacity and deformation, under the same load conditions, the mechanical performance of different structural forms will also show different states; within the design life of the building, the designer considers the possible structural Different loads will also lead to different mechanical properties even under the same structural form. Therefore, finding a structural form with optimal mechanical performance is an important reference in structure selection.

Meet the requirements of the feasibility of coal storage yard structure construction

Any design result is ultimately realized by manufacturing and installation. It can be said that the building function is ultimately reflected by the application of construction technology. Therefore, in the process of structure type exploration, it is necessary to combine the specific construction requirements of the site, to ensure the construction quality and construction safety, and even to consider the difficulty of construction, especially the structure production and installation method, the detailed drawings of structural nodes, the selection of construction machinery, In terms of construction period requirements, construction cost control, and the impact of construction site conditions, a practical and feasible structural form is obtained to achieve a seamless connection between design and construction.

4) To meet the economic requirements of coal storage yard construction

On the premise of satisfying safety and quality, the structural selection should take into account the construction economy, and should choose a plan with less steel, strive to reduce the construction cost and post-construction maintenance cost, and realize the rational use of resources.

5) Meet the reasonable span and width requirements of the coal storage yard

In daily production and life, people’s requirements for the span and width of buildings are getting higher and higher, in order to obtain more space for use, but the requirements for the span and width of each structural form are different, which requires When selecting the structure, consider the requirements of reasonable building span and width to ensure that the design work can meet the requirements of the building’s bearing capacity, deformation requirements and the requirements of no overall instability. Therefore, the most reasonable structural form must be considered when selecting the most reasonable structural stress. Factors of building span and width.

The above are just a few aspects that generally need to be considered when selecting the structure of the coal storage yard, but the angle considered in the actual work is not limited to this. The form is more reasonable, and it is inseparable from the comprehensive consideration of relevant factors, comparing different structural forms in terms of cost, construction, etc., and proceeding from the actual, comprehensive and comprehensive analysis to select the most reasonable structural form.

Due to the fact that this project is located in an irregular site, the terrain is relatively special, and the influence of existing buildings and structures around the site, under the condition that coal storage is required to be 40,000 tons, in order to be able to use the most economical investment to meet the maximum coal storage yard use function, and other factors affecting the structure selection, the final decision was made to select the structure suitable for this project by comparing the construction cost of one ton of coal with the lowest construction cost.

The formula for calculating the construction cost required to store one ton of coal:

A=C/T

(1) In the formula:

A – the construction cost required to store one ton of coal;

C – project cost;

T – the total amount of coal storage.

According to the calculation formula (1), the results are obtained and filled in Table 1. The construction function, construction area, project cost and coal storage cost are compared to determine the choice to build the coal storage yard with an irregular shape structure.

Table 1 Comparison of irregular shape structure and regular shape structure

|

Building style |

building function |

Building area/square meter |

Project cost/10,000 yuan |

Coal storage cost yuan/ton |

|

regular shape structure |

Unfavorable subsequent construction |

8800 |

2300 |

575 |

|

irregular shape structure |

Reasonable |

11000 |

2100 |

525 |

The structure is of great significance to architectural engineering and is an indispensable process for designing and researching work plans. Only after a scientific and complete structure selection process can it have a positive impact on the overall architectural design.

Three spatial structure models are established by computer, and the optimal structure suitable for this project is selected by comparison. As shown in Table 2:

Table 2 Choice of spatial structure system

|

serial number |

Spatial structure |

sketch |

Features |

|

1 |

Triangular tube truss |

|

Therefore, it is easier to play the role of materials, the consumption of materials is economical, and the structure is light. |

|

2 |

Portal steel frame |

|

Simple force, clear force transmission direction, high component production efficiency, easy batch processing, construction cycle shorter term |

|

3 |

Flat Pyramid Space Frame |

|

Fewer types of rods, easy to produce, mainly stressed along the axial direction, scientific force, material saving, high overall quality, high rigidity, and strong seismic performance |

After calculation, among the three schemes of triangular pipe truss, portal steel frame, and flat pyramid space frame, the flat pyramid space frame has the highest value coefficient, so the design of the flat pyramid space frame is the optimal solution.

4.2 Selection of space frame form

The flat space frame is divided into two types: cross truss system and pyramid system, of which the more reasonable is the pyramid system, which has stronger rigidity. The height of the space frame is proportional to the span length, and the size of the space frame matches the height of the space frame. The angle of the webs of the space frame is preferably 45°. The ratio between the height and the short span of the space frame is usually about 1/15, the members are usually made of steel pipes, and the node is usually a ball node. Common space frame forms are shown in Table 3:

Table 3 Selection of space frame form

|

serial number |

Flat space frame |

sketch |

illustrate |

|

1 |

Quadrangular pyramid system |

|

The inverted quadrangular pyramid is the constituent unit of the quadrangular pyramid system space frame. The upper and lower chord plane space frame structures are square, and the centroid of the upper chord space frame is the intersection point of the lower chord space frame. Inverted quadrangular pyramid element |

|

2 |

cross truss system |

|

The space frame structure consists of two or three groups of plane trusses. The upper and lower chords of the space frame are of equal length and are generally designed as a tie-rod system.rod under pressure, the angle between the inclined rod and the chord rod should be between 40° and 60°, and the vertical rod is shared by each group of plane trusses |

|

3 |

triangular pyramid system |

|

The upper and lower chord planes are all triangular meshes. The rods are uniformly stressed and are geometrically invariant. The overall torsional and bending stiffness is good. It is suitable for large and medium-span and heavy roofing buildings. When the building plane is triangular, Best for hexagons and circles |

To sum up, among the quadrangular pyramid system, cross truss system, and triangular pyramid system in the flat space frame system, according to the span, length and height of a coal yard, choosing the triangular pyramid system is more cost-effective than the other two systems in terms of cost, safety, quality, and efficiency. There are outstanding advantages in progress and use, so this system is selected as the system form of the flat pyramid space frame.

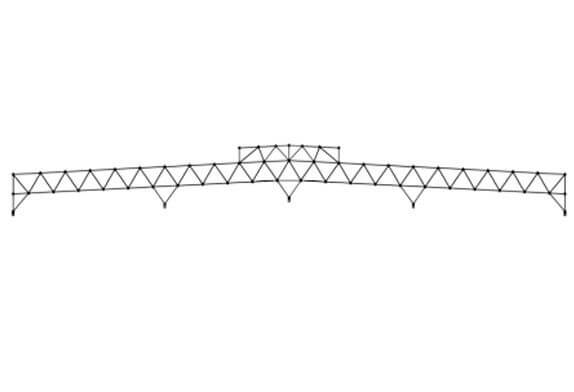

At present, the object design of complex situations (nonlinear, circular, dynamic geometry) has difficulties in the construction of geometric shapes and the design of each project stage. This project is an irregular spatial space frame structure, and the outer nodes of the space frame upper chord are supported on the concrete column top by plate support. Through consulting the relevant data of steel structure design of dry coal shed, it is found that the mechanical properties of dry coal shed are affected by many factors, among which the thickness of the space frame, the size of the space frame, and the position of the support have a great influence on the mechanical properties of the structure. This project adopts the form of a square cone, size 5m×5m, height 2.85m, using the bolt ball space frame node. The roof is supported by the upper chord ball joints of the space frame. The main purlin of the roof is C180×70×20×2.5, with a spacing of 5m, and the secondary purlin is C180×70×20×2.5, with a spacing of 2.5m. The spatial structure system adopts a bidirectional orthogonal steel truss as the load-bearing structure of the whole building roof. The upper and lower chord rods and belly rods of the roof truss are round tube sections. The positive plane and section of the roof truss are shown in Figure 2 and Figure 3.

FIG. 2 Positive plan of roof space frame of a coal yard

FIG. 3 Section of roof space frame frame of a coal yard

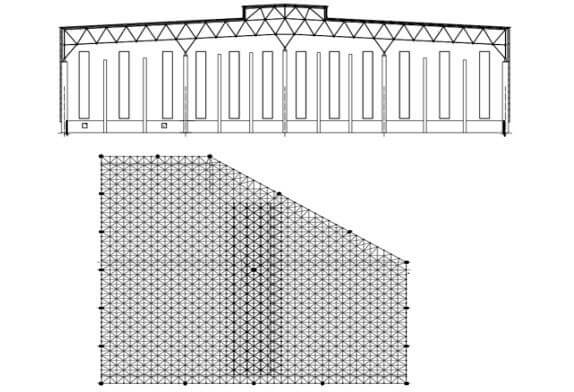

The size of the engineering structure is 111 meters in width from east to west and 119 meters in length from north to south. The middle supporting column is added at axis D/5. The size of the column is φ 1800mm and the height is 20.47m. The structure is in the form of a bolt-ball node is put quadonal double layer network frame, the surrounding multi-point and multi-point support in the middle column, the maximum net span of the network frame is 59.5 meters, the top elevation of the network frame is 24.275 meters, 3m high coal retaining wall and concrete column are set around (column spacing is 10 meters), and embedded iron parts are set at the top of the column to fix the spherical bearing. The roof is 0.6 thick grey single laminated color steel plate self-waterproof roof. See Figure 4 for the space frame structure.

FIG. 4 Section of space frame structure and space frame layout

This project is a typical irregular slope space frame structure type, and the influence of stress changes on the strength and stability of the space frame structure during construction is very sensitive. The more irregular the space frame structure is, the more complex the stress changes of the rod structure and the more uncontrollable factors of construction are, leading to the deformation and instability of the rod structure during the installation of the space frame structure.

In order to ensure the construction quality and safety of the irregular space frame, it is the key to determine a scientific and reasonable space frame installation scheme to ensure the construction quality of the irregular space frame. Due to the irregular shape of the steel space frame in this project, and the existence of slope in the design of the space frame structure, it is impossible to install a track for sliding construction, so it is improper to adopt the high-altitude sliding method. The maximum span of the space frame is 59.5 meters, although it does not belong to the large-span space frame (Note: The span of 60m is called a large-span space frame), because there is only one column support in the middle, if the method of slitting (block) will be limited by the support conditions, the division of unit block or unit strip has a great influence on the whole space frame structure, the structure can not be successfully installed and butt, so the slitting (block) method can not be used; The total weight of the entire space frame is about 600 tons, and there are other built buildings around the proposed building that limit the crane station, so the overall installation of mechanical equipment cannot be realized, and the overall lifting method is not appropriate. If the high altitude bulk method is used for construction, the maximum height of the lower string bars (including supports) is 20.475m, so a large number of temporary supports need to be set up in the installation area of the space frame, high installation cost, construction period extension, high altitude assembly workload, so it is not suitable to use only high altitude bulk scheme.

In order to speed up the construction progress and reduce the construction cost, ensure that the engineering quality and safety guarantee under the premise of production as soon as possible, careful analysis of the conventional method is superior to domestication, the irregular space frames artificially divided into two categories, rules and irregular area, general idea of irregular rack installation order from irregular to the rules, installation is difficult because of irregular region, many uncontrolled factors, security is low, It was decided to adopt ground installation and overall lifting in this area, and the other areas were divided into three regular areas, which were easy to install. High altitude scattered construction was adopted, and 3D3S software was used to simulate construction conditions. The construction data obtained were good.

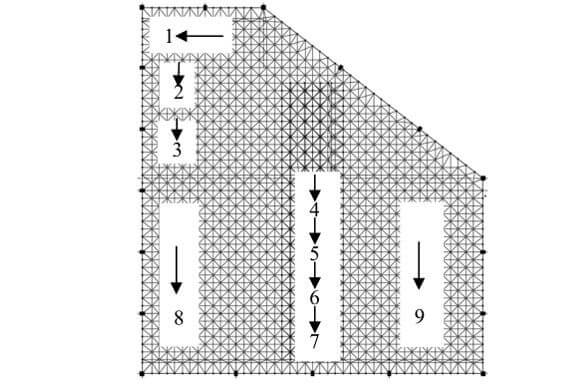

Therefore, it is determined to use the “combination of overall lifting of starter frame and high-altitude bulk” scheme for construction, and the installation sequence is shown in Figure 5

Figure 5 space frame installation sequence

According to the characteristics of the coal bunker project, and the load capacity of the lifting equipment, the overall installation of steel space frame installation ideas for the first

The whole lifting method is used to install the starting frame, and the starting frame is selected in the irregular area of the C-H axis /4-9 axis, and the steel network frame installation sequence After the starter is installed, follow steps 1 to 9 to complete the air bulk.