+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1. Space frame structure and its characteristics

The space frame structure refers to the connection of steel rods to build a shelf for building construction. There are double-layer space frame structures and multi-layer space frame structures with more layers.

①The space frame structure has the characteristics of high rigidity and good stability in the construction of buildings, so it is widely used in large-span buildings, such as gymnasiums.

②The composition of the space frame structure is relatively simple, mainly using steel rods, in the cost is much cheaper than the traditional building structure.

③ After the space frame structure is combined, it serves the building together and is also an independent structure. Therefore, when there is a problem with a small part of the space frame structure, it will not have an excessive impact on the overall function of the building.

④ During the installation of the space frame structure, the operation methods that the construction personnel need to master are relatively simple, and it is not easy to make mistakes.

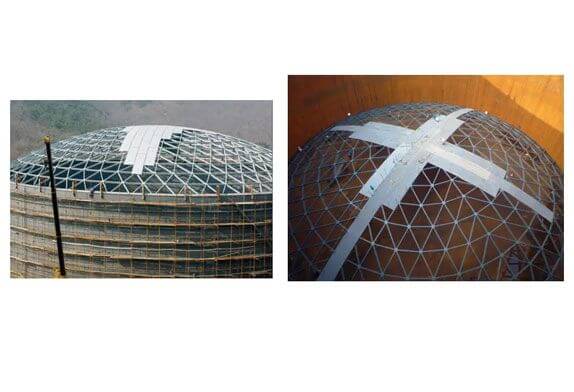

2. Reticulated shell structure and its characteristics

The main feature of the reticulated shell structure is the grid-like structure of its curved surface, which helps it to withstand more external pressure in building applications. Similar to the space frame structure, the reticulated shell structure is also divided into two types: the double-layer reticulated shell structure and the multi-layer reticulated shell structure. In addition, the reticulated shell structure and the reticulated frame structure are also more used in the construction of large-span buildings. In addition, the reticulated shell structure has some other characteristics:

①Compared with the space frame structure, the reticulated shell structure is more economical in terms of material requirements, and the corresponding cost will be smaller.

② The shape of the reticulated shell structure is more beautiful, and in addition, there can be various types of changes. The existing reticulated shell structures with different shapes include spherical, cylindrical, hyperboloid, etc.

③The external force on the reticulated shell structure can be evenly distributed on its entire surface, so the structural stability is very good.

3. Fabrication of space frame and reticulated shell structure

In the process of preparing the reticulated shell and space frame structure for building construction, firstly, design the required structural drawings of the reticulated shell and space frame structure according to the specific conditions of the actual construction, and select the appropriate structure type. After that, the various parts of the structure are processed according to the parameters of the drawing design. For example, if the design of a welded hollow spherical space frame, it is necessary to process the rod and the hollow sphere separately. In the process of rod processing, the rod must be guaranteed straight, and the length of the rod also needs to meet the design value, it is best to leave a certain margin in the processing process. The last step in the production of the reticulated shell and grid structure is to complete the assembly of parts according to the existing assembly technology after checking the quality of the processed parts

4. Assembling technology of spaceframe and reticulated shell

4.1 Check the quality of the space frame and the reticulated shell structure

In the process of building construction, in order to save the cost of transportation and try to avoid the damage to the space frame and reticulated shell structure, the parts of the structure will be directly transported to the construction site, and then assembled. Before the structure is assembled, the quality, type, material, etc. of the parts and components transported to the construction site need to be checked. Make sure that it is indeed the required structural parts, and that all parts are not damaged, and the dimensions and specifications also meet the construction standards, and then the structural assembly can be officially started. In addition, according to different construction techniques and building designs, the assembly of the parts of the space frame and the reticulated shell structure also needs to follow a certain assembly method for specific assembly, for example, the way of block assembly.

4.2 Assembling technology of welded hollow spherical space frame

If the construction of the building adopts the welded hollow spherical space frame structure, then in the assembly process, it is necessary to select the assembly sequence suitable for the type of space frame and try to avoid the structural deformation of the grid frame parts due to welding. When assembling the welded hollow spherical space frame structure, the assembly method is generally selected to spread from the middle to the surrounding, and sometimes the method of splicing from the middle to both sides is also selected. When this space frame splicing method is in progress, both ends of the space frame structure can be adjusted freely. After welding a section of rods, the construction personnel can check whether the size and shape of the completed structure meet the design standards. After ensuring that the construction quality of the former is up to the standard, the welding of the lower section members is continued.

4.3Assembling technology of bolted ball joint space frame

If the space frame structure selected for the building is the type of bolted ball joint, then in the process of assembly, it is necessary to start from the bottom chord, and only after confirming that the parameters such as its axis and elevation meet the design requirements, can it be fixed with bolts live. In the process of continuing to bolt the web frame of the space frame, it should be noted that the bolts used for fastening cannot be tightened at one time, so as to avoid the adjustment of subsequent splicing. The last step is to connect the upper strings of the space frame so that the space frame structure is only considered to be connected. At this time, the spacer at the lower chord can be used to adjust the entire grid structure as a whole. After the adjustment is completed, the bolts that have been left before can be completely tightened.

4.4 Assembling technology of reticulated shell

In the process of assembling the reticulated shell structure, it is necessary to use a professional auxiliary formwork to help the reticulated shell structure in the early stage of assembly, and first complete the assembly of small unit structures. The assembled formwork can help the splicing of small unit reticulated shells to make them more accurate in shape and structure. In the process of assembling the reticulated shell structure, the construction personnel need to accurately control the coordinates of each node, and the position of the nodes can be determined with the help of the instruments used for positioning and measuring distance. Select the assembly method and sequence suitable for the type of reticulated shell structure. For example, for the assembly of the double-layer cylindrical reticulated shell structure, it is more suitable to assemble from both sides to the middle of the structure, and pay attention to the symmetry of the structures on both sides during the assembly process.