+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

3.3、Construction technology

(1) Deepening design of the construction process → setting out and positioning → bracket production → bracket installation → wire duct and ladder frame installation → grounding connection → acceptance.

(2) In-depth design bridge construction occupies a large space, use BIM technology to communicate and coordinate with other disciplines before construction, grasp the possible intersection positions with steel space frames and steel horse roads during construction, and make sure the structure of the bridge installation position Have a preliminary understanding of load-bearing capacity, cable weight, length, specifications, etc. Carry out in-depth in-depth design, and cooperate with various disciplines to complete the layout of the bridge frame and the plan for the branches of the bridleway and the cable-stayed rods of the steel space frame for the bridge frame to ensure that the position of the bridge frame is correct after installation, the direction is reasonable, the operation is safe, and it is capable of construction. Operability and subsequent maintenance testing. The in-depth design must consider factors such as construction quality and safety, carefully review the design drawings, raise problems in the drawings in a timely manner, and hand them over to the design unit for processing as soon as possible.

(3) Setting out positioning According to the complex roof structure and the radial shape of the civil engineering positioning axis, it is extremely difficult to measure, position and set out the installation of the bridge. In order to ensure the quality of the bridge installation, the management team specially selected “BIM model lofting robot” to replace the conventional measurement The instrument performs positioning and setting-out for the installation of the bridge. In order to make the workers proficient in the operation skills of measuring and setting out, all workers have been trained on the theoretical knowledge of the installation quality of the bridge bridge and the operation training of “BIM stakeout robot”, and they can only work after passing the examination. Use BIM technology to deepen the layout of the bridge model, and input the electronic version of the deepened BIM model drawing into the stakeout robot, and the stakeout robot automatically reads the drawing data and intelligently positions the points. The survey work is done to complete an area or a system, and then recheck an area or system. The results show that the setting-out positioning accuracy of the setting-out robot is accurate and meets the requirements of construction and specification standards .

(4) Before the bracket production and installation, the management team decided to change the conventional bracket installation form and optimize the bracket form and installation mode after discussion and on-site comparison and selection of the bracket installation method. The galvanized angle steel is processed and manufactured, and the manufacture must match the designed bridge type. The special-shaped bridges and bends in special parts are assembled and prefabricated in advance. Special parts are specially processed in a small area on site.

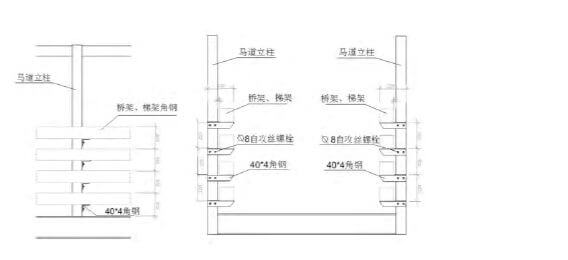

The support and hanger is fixed on the inside of the railing columns on both sides of the horseway with self-tapping bolts (2*Φ8), which has the advantages of zero welding, simple and convenient construction equipment, and firm and reliable fixing. The horizontal spacing of the supports is 1.5~2m, and the vertical spacing is not greater than 2m. See Figure 2 for the schematic diagram of the section and elevation of the bridge frame installation.

Figure 2 Schematic diagram of section and elevation of the bridge frame installation

(6)Bridge installation

1)Brackets or hangers shall be set at the ends of the horizontal bridge, at the corners of the junction boxes (cabinets), at the ends of turning and crossing deformation joints, at the three ends of the horizontal tee, and at the four ends of the horizontal cross, and The distance from its edge is not more than 500mm.

2)When the straight line bridge is laid along the wall, there should be no less than one fixed point between each slot box and ladder frame, and there should be fixed points at corners, branches and ends. Greater than 500mm.

3)When installing the horizontal bridge, ensure that the support and hanger is horizontal and vertical, the horizontal deviation of the metal box and ladder frame is not more than 2‰, and the total length is not more than 20mm.

4)The bridge frame and the ladder frame are fastened with connecting piece nuts, flat pads and claw type pads are complete, and the length of the nut exposed threads is the same.

5)The connection position of the bridge frame should be set reasonably to ensure the convenience of construction and maintenance.

6)The bridge frame is connected with the distribution box and cabinet, and adopts the method of entering from the bottom and exiting from the bottom.

7)The bridge frame is led up from the structural floating island to the steel space frame bridleway, and the prefabricated portal frame is set by the steel structure support tube, and the bridge frame is led up to the bridleway through the prefabricated portal frame.

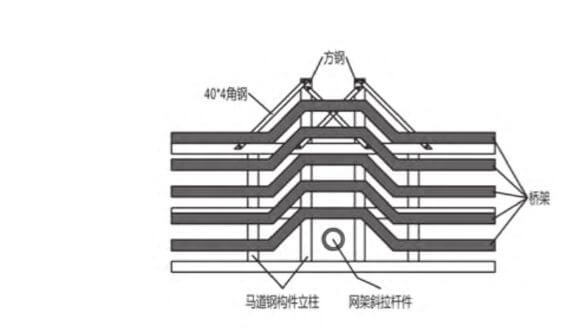

8)When the cable-stayed rods of the cable-stayed bridge frame and the cable-stayed space frame conflict, resulting in insufficient installation space for the bridge frame, the square steel that matches the cross-sectional size of the column should be used for full butt welding on the steel frame column where the bridge frame is installed, and the welds are fully welded , no meat biting phenomenon, brush anti-corrosion paint treatment, use two 40*4 angle steel to pull the square steel on both sides to make a stable support, the angle steel and square steel, and the railing of the horseway are fixed firmly with self-tapping screws. Supports and hangers are installed before and after the bridge is turned over (see Figure 3)

Figure 3 Schematic diagram of the cross-section of the conflicting nodes of the cable-stayed members of the bridge frame and the horse-way space frame

9)Near the branch of the bridleway, the side of the installation bridge is fixed with a flame-retardant metal groove box and the railing of the bridleway with self-tapping screws. The subpackage box is connected with the flame-retardant metal tank box at the bottom of the catwalk (one side panel is cut off), and all cuts and welds are treated with anti-corrosion. The flame-retardant metal tank box used to connect the sub-package box and the bridges of each system and the sub-package box are equipped with partitions to separate strong and weak current cables .

There are more and more super-large plane steel structure buildings, the structure of the bridleway is more and more complex, and the installation of the bridleway bridge is becoming more and more difficult. The connection method of the electric box, the branch method of the bridge frame at the branch of the horse road, and the safety control of high-altitude operations during the installation process. Therefore, before the construction of the super-large roof steel space frame inner bridle bridge, construction planning should be done, the necessary depth of in-depth design should be carried out, and the quality control in the process should be strengthened to ensure the installation quality of the super-large roof steel space frame inner bridle bridge, and ensure that the construction can be completed at one time .