+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The installation methods of steel space frame are mainly divided into overall lifting method, air sliding method, high-altitude bulk method, strip or block method, and various combination methods. The overall lifting method is to assemble the space frame on the site prepared in advance. After the assembly is completed, use the vertical and horizontal transport machinery to transport the space frame to the installation site for hoisting work. After the preliminary hoisting is completed, the overall adjustment and reinforcement will be carried out. It is large and requires high machinery, space and manpower, but the quality of the assembled space frame is high. The air sliding method uses a slidable frame to install the space frame. This method has certain safety hazards. The slidable frame may be deformed during the dragging process. The frame needs to be checked at any time, and the special supervision will also slow down the construction speed. The replacement of scaffolding by sliding frame body can save the cost of scaffolding. The high-altitude bulk method is to set up an operation platform in the construction area of the space frame. The operators use the operation platform to assemble the components of the space frame. The consumption of materials is relatively large, but at the same time it has relative safety. The strip or block method is to divide the space frame into strips or blocks, and each strip or block is a unit, and then hoisted to the corresponding position on the design drawing in turn, and then the overall installation operation is carried out. The strip or block units need to ensure No geometric deformation occurs, and the accuracy of the relative position is guaranteed. The construction is more difficult, but the requirements for the site and mechanical equipment are relatively low, and the construction quality and safety are guaranteed to a certain extent.

3、3D modeling of long-span spherical space frame structure

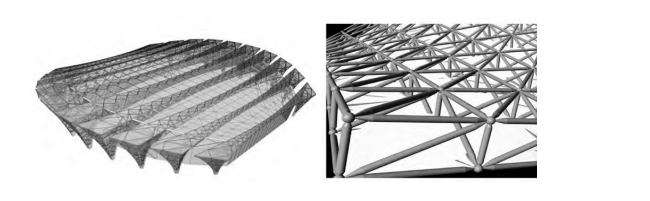

Nowadays, 3D technology is becoming more and more powerful and perfect. Using the current 3D modeling software, 3D modeling is carried out on the construction site according to the design drawings before construction (see Figure 2). Combined with the actual situation on the site, a construction simulation of the large-span spherical space frame structure is established, which is displayed intuitively and comprehensively from assembly to hoisting, and problems that may arise during construction are analyzed to make improvements to ensure the feasibility of construction technology.

Figure 2 Three-dimensional schematic diagram

4、Key points of construction operation

4.1 Construction preparation

1) First, inspect the quality of all components of the space frame to ensure the material quality of each component. The inspection contents include: model, specification, material, weight, factory certificate, inspection record, material inspection report, and observation of the shape for deformation and cracks , a large amount of corrosion, etc., to ensure that all components can meet the design requirements.

2) Number the corresponding components according to the design drawings, indicate the section number, coordinates, bar number, diameter, and length, and conduct a review after marking to ensure that the specifications and dimensions of the components are consistent with the installation parts, and it is the blanking work for the components Be prepared to facilitate subsequent component management and component installation.

3) Pollutant cleaning is required before space frame processing to remove pollutants such as scale and rust. In special cases, pickling and phosphating can be used to facilitate subsequent surface cleaning.

4) Conduct safety and technical disclosures to all relevant personnel involved in the construction, and set control points on site to control and correct the coordinate positions of space frame nodes.

5) Measures should be taken on the web of the lower chord during blanking to facilitate the increase of weld thickness. The inward position of the two ends of the lower chord should be set at a length of 30-50 mm, a liner with a wall thickness of 2 mm, and an outer diameter of the liner. Match the inner diameter of the lower chord, it should be 0.3~0.5mm smaller than the inner diameter of the lower chord, and expose the end of the lower chord by 3mm, so as to strengthen the quality of the welding seam.

6) The arching method of large and small space frames shall be arched in one direction (short side direction) after being approved by the design.