+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

4.2 Space frame assembly

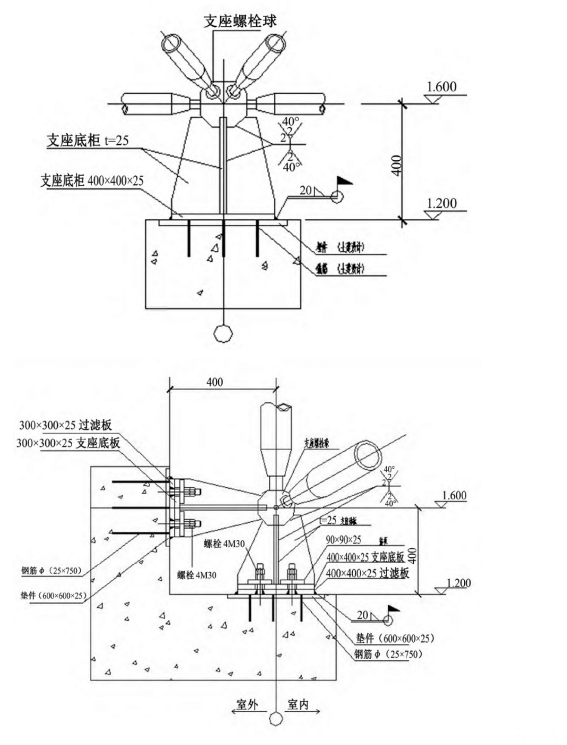

4.2.1 Space frame support installation

The space frame support of this project is a cross-rib type, and the bottom plate of the support is welded to the buried plate pre-buried on the top of the column (see Figure 3). The elevation and center line of the embedded parts need to be rechecked before the support is installed to ensure that the coordinates are accurate. The support is initially fixed with the edge line of the support combined with the cross center line. The fixation method is spot welding. The welding method is firmly welded to the support.

4.2.2 Space frame hoisting

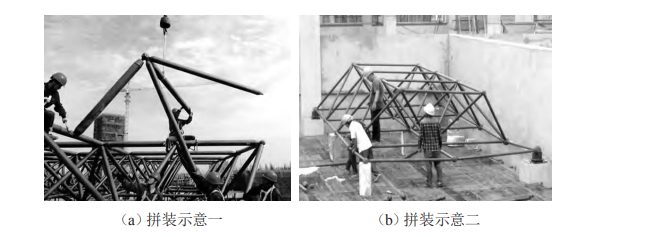

Each small unit assembled on the ground uses two 25t cranes to lift the assembled part to the embedded part on the top of the column as a whole, and then carry out high-altitude bulk assembly in the direction of the other end in turn. The assembly direction can be freely selected. Either end or mid-end is fine. The space frame between two adjacent supports is used as the starting point until the overall assembly of the space frame is completed. In the process of space frame high-altitude bulk assembly, start from the middle of the starting area, assemble the upper string quadrangular pyramid units, and gradually complete the assembly of the upper string quadrangular pyramid units. When the three upper string quadrangular pyramid units are assembled, the lower string quadrangular pyramid units can be assembled. Expand the assembly to both sides. After installation, it is necessary to inspect the plane size deviation, support point distance deviation, and adjacent support point height deviation of the space frame (Figure 4).

Figure 4 space frame assembly

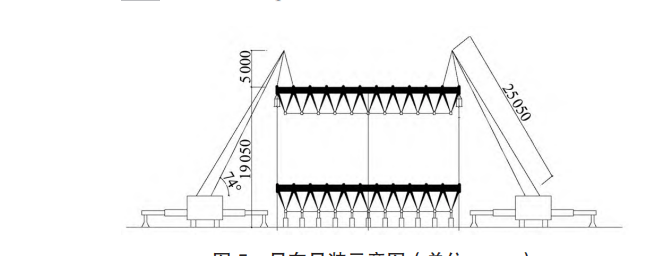

The included angle between the boom of the crane and the ground should be 72°~75° during hoisting (see Figure 5). The working range during hoisting is about 7m in radius. Should be above 24.6m. 4.2.3 Welding 1) Requirements for welding rods: The welding rods should be dry, and the welding rods should be dried in humid weather.

Figure 5 Schematic diagram of crane hoisting (unit: mm)

2) Welding seam requirements: Personnel with relevant skill certificates should be appointed to carry out the welding work, and the quality of the weld seam must be strictly required. Overburning, cracking, inclusions, and air bubbles must not occur, and the use of steel bars or other materials to mix into the weld seam is prohibited. The thickness of the weld seam is not high. Should be less than 6mm, and the welding seam of the component shall be inspected according to the requirements of the design drawings.

3) When welding the bearing ball, it is necessary to select a suitable electrode for welding according to the steel. Different sizes of bolt balls have different preheating degrees. The preheating temperature of bolt balls with a diameter of less than 200mm needs to reach 150-200°C, and the preheating temperature of bolt balls with a diameter of ≥200mm needs to reach 200-300°C, and the maximum temperature should not exceed 350°C.

4.2.4 Apply fire retardant paint

In order to ensure the quality of space frame components, it is necessary to use anti-corrosion coatings for anti-corrosion treatment of space frames, and to paint fire-resistant coatings. Fire-resistant coatings should be made of low-carbon and environmentally friendly materials, such as gypsum-based materials. The coatings used must be fire-resistant The management department appraises and approves and has quality assurance materials.

5、Comprehensive advantages of this construction technology

1) With the operation platform, the safety of construction operators has been greatly improved, avoiding potential safety hazards, eliminating safety accidents, and facilitating the overall operation of construction operators on the large-span spherical space frame construction.

2) The ground assembly and the painting of the paint play a role in guaranteeing the improvement of the construction quality, and also play a vital role in improving the project management level, construction technology level and acceptance rate. It improves the overall function of the large-span spherical space frame, strengthens the force on the space frame, and enhances the ability to withstand concentrated loads, asymmetrical loads, and local overloads.

6、 Economic benefits

Taking the construction period, manpower, machinery, and materials of this project as the starting point, using this construction technology shortens the overall construction period by 10 days compared with the overall construction period of 60 days, reduces the crane rental fee by 600 yuan/hour×6h×10d=36,000 yuan, and the scaffold rental fee is 3,220 yuan /d (converted cost) × 10d = 32,200 yuan, a total of 68,200 yuan, the cost of labor costs decreased by 16.7%, and the consumption of 180 man-hours in the construction process was reduced. The labor cost was 400 yuan × 180 man-hours = 72,000 yuan. Comprehensive calculation: the use of this construction technology saves about 140,200 yuan in labor, machinery, and material costs.