+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The upper part of the clinker storage in the cement factory area is mostly a large-diameter conical steel space frame structure, and the lower part is a large-volume concrete cylinder structure, and the building height of this type of building is generally relatively high, so that people can directly see it.

Huge structures The shape will bring a certain sense of oppression to the surrounding environment and vision. With the increasing call for “de-industrialization” of industrial buildings, this kind of large-scale cement building will slightly conflict with the new “beautiful factory”, so it is necessary to beautify the facade of the clinker storage in the factory area Lighting enhances the visual image of the structure.

2 Structural scheme selection

The so-called de-industrialization is to require industrial buildings to have architectural artistry like civil buildings, to create pleasant, beautiful, fashionable, and culturally connotative architectural spaces and environments, and to break the stereotyped rigid image. Based on this purpose, and in order to make full use of the local surrounding resources, adopt a layout method more suitable for the current environment and a more people-friendly structural form to create a more beautiful urban landscape, provide a more suitable sense of space and visual effects and based on the existing The volume of the building is redesigned on the facade decoration, and strives to achieve the integration of the architectural style and the local landform with the surrounding buildings. The visual experience of the tall volume is weakened through the design method, so that the building is closer to modern industrial buildings and surrounding industries. The style of the garden achieves the integration of architecture, landscape and local environment. The design adopts the expression method of modern architecture, so that the architectural style adapts to the local environment and buildings. The space frame structure selection is to surround the entire clinker warehouse with a cylindrical space frame structure, and the outer facade effect should be as light as possible. , High-strength and durable exterior wall materials, using hollowed-out facade treatment, minimizes the impact of wind load on the exterior wall and the entire building structure, thereby reducing the use of reinforcement and large cross-section components, reducing engineering volume and cost, and ensuring use Safety and durability, while enhancing the visual effect.

3 Project Overview

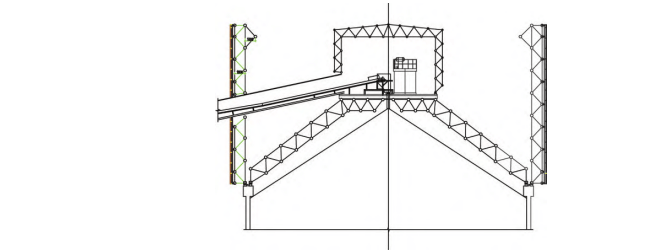

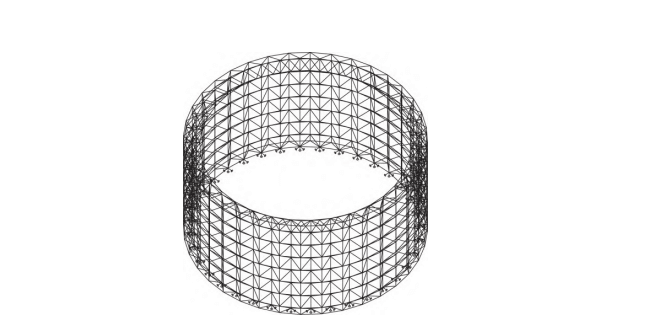

The location of this project is a cement factory in Anhui Province. According to the requirements of the owner, the steel space frame structure of a new clinker warehouse needs to be beautified and brightened. The main structure of the clinker silo is the same as the conventional one. The upper part adopts a conical steel space frame structure, and the lower part adopts a large-volume concrete cylinder. In order not to affect the use of the clinker silo space frame and achieve an aesthetic effect, many considerations have been made After making a plan, it was decided to use the concrete cylinder of the clinker silo, and add a cylindrical space frame around it to enclose the entire silo top space frame. The main section form of the overall architectural shape is shown in Figure 1. According to the process conditions and beautification and lighting requirements, the diameter of the cylindrical steel space frame is 41.44m, and the thickness of the space frame is 1.5m. In order to increase the overall rigidity of the space frame, a ring is added to the top of the space frame as a reinforcement ring. The height of the entire space frame It is about 22.75m. The cylindrical steel space frame support is arranged on the ring beam of the prestressed reinforced concrete warehouse wall. The ring beam elevation is 28.80m. Surrounded by a space frame structure, the three structural forms all adopt the form of double-layer upright square pyramid space frame, and the joint forms are bolt ball joints and welded ball joints. The cylindrical steel space frame structure calculation and modeling are set at the lower inner chord. 36 supports, the facade is decorated with a lightweight aluminum grille.

Figure 1 Sectional view of the overall architectural shape of the clinker warehouse

3.1 Design load and parameters

Load situation:

(1) The value of space frame dead load is 0.5kN/m2;

(2) Live load and gray load are not considered for the time being due to structural reasons;

(3) The value of the wind load is 0.35kN/m2, and the height of the space frame is queried according to the regulations, and the wind pressure height change coefficient is taken according to the type B site, and the wind vibration coefficient is considered to be 1.20;

(4) The temperature difference is +25°C, -25°C;

(5) According to the seismic code query, it is known that the seismic fortification intensity of this project is 6 degrees, the basic seismic acceleration of the structure design is 0.05g, the earthquake group is the first group, and the construction site category is II;

(6) Due to the installation of the aluminum grid during the construction stage, there may be hanging baskets erected on the inner and outer chords of the uppermost layer of the space frame and the ball nodes of the reinforcing ring, so the load of this part will be superimposed on the nodes in advance when the space frame is modeled and loaded. superior.

Material situation: Determined according to the provisions of the technical regulations for space grid structure:

(1) The rods, sealing plates and cone heads of the space frame structure are all made of Q235B;

(2) The bolt ball is selected from No. 45 steel that conforms to the current industry standard;

(3) The high-strength bolts are selected from the material 40Cr or 20MnTiB that meets the requirements of the “Alloy Structural Steel” specification, and the bolt grades are divided into M16~M36 (10.9S) and M39~M64 (9.8S). Design parameters: space frame structure design calculation parameters are determined by relevant specifications such as seismic design specifications, spatial grid technical specifications and steel structure design specifications:

(1) The average slenderness ratio of the tension and compression rods of the space frame is 180, and the rods of the support accessories are set as the key rods;

(2) The stress ratio parameter of the space frame is set to 0.93;

(3) The setting of the stress ratio of high-strength bolts and sleeves is consistent with the connected rods and is also 0.93;

(4) The deflection limit of the space frame is 1/125 span according to the regulations. Its calculation model is shown in Figure 2.

Figure 2 space frame calculation model

Load combination: The load combination of the space frame structure is carried out according to the load code and the seismic design code, and the horizontal and vertical earthquake conditions of the earthquake are considered.

3.2 Calculation result analysis

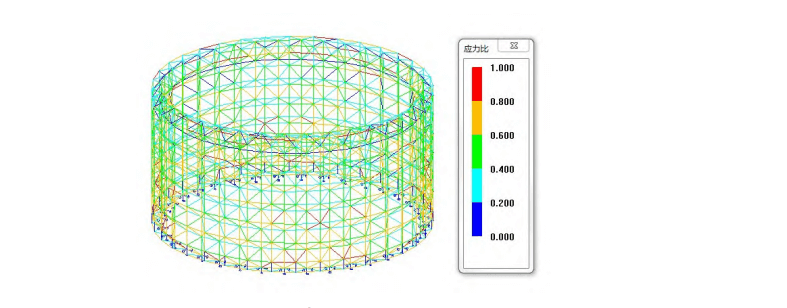

The cylindrical space frame structure adopts the space structure program MST software of Zhejiang University to carry out static analysis and calculation of the space frame, and then uses the steel structure program 3D3S software of Tongji University to carry out static analysis and calculation, and compares and verifies the results calculated with the MST software, and then uses the 3D3S software Dynamic analysis and stability calculations. Static calculation and analysis of the steel space frame shows that the rod specifications are Φ60mm×3.5mm, Φ76mm×3.75mm, Φ89mm×4.0mm, Φ114mm×4.0mm, Φ140mm×4.0mm, Φ159mm×6.0mm, and the high-strength bolts are M20, M24, M27 , M30, M36, the bolt ball joint specifications are Φ100mm, Φ110mm, Φ120mm, Φ130mm, Φ150mm, Φ180mm, the stress nephogram of the space frame member is shown in Figure 3, and the result meets the stress limit of the space frame. The maximum horizontal displacement of the space frame is 42.9mm in the X direction and the Y direction, which meets the displacement limit requirements of the specification. The total steel consumption of the space frame is about 65t, the design value of the maximum support reaction force is 260kN, and the radial level is 120kN. Under the same load, material and parameters, the results calculated by 3D3S software are almost the same as those calculated by MST software, so the accuracy of this model can be verified.

Figure 3 Stress cloud diagram of member

The rapid development of the cement industry puts forward higher requirements on the cement plant environment and its vision. Beautifying and brightening the cylindrical space frame is to weaken the visual perception of the structural form of the tall clinker storage.