+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The selection and construction of the space frame is an important part of the design of the space frame structure, which should be considered comprehensively according to the material supply, construction conditions and production and installation in order to achieve better technical and economic benefits. Jiaozuo City Staff Gymnasium is an indoor stadium with a capacity of 3500 people, with a construction area of 2016m2 and a flat-plate mesh frame for the roof structure.

1 Determination of technical parameters

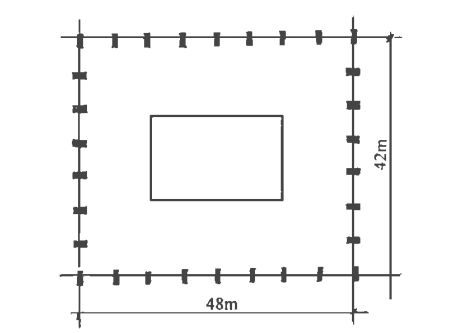

The gymnasium is located in the central part of Jiaozuo City, with a plan size of 48m long in the north, 42m wide in the east and west, and the west elevation facing the main street of the city, North Democracy Road. Its plan schematic is shown in Figure 1.

Figure 1. Stadium layout

According to the design and construction requirements of the space frame specification and the plane dimensions of the modulus, the space frame size is determined as follows.

Space frame thickness: h = (1/12~1/16)L.

Grid size of the upper and lower chords of the space frame: a = (1 / 10 ~ 1 / 16) L

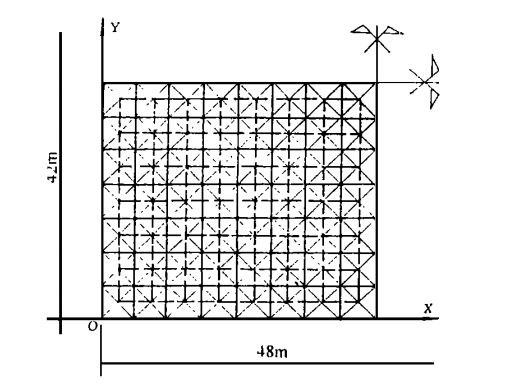

Where L = 42m, the short span size. After calculation, take h = 3.0m, a = 3∙0, so the grid size is 3m × 3m, a total of 14 × 16 grid.

2 Selection and characteristics of the space frame

Roof load: the external load is taken as 400kg/m2 (according to the roof to do legal); the self-weight of the space frame is 50kg/m2 (according to the specification initial junction).(1)According to the grid number and plane size, the two-way orthogonal orthotropic quadrangular cone space frameis used (mainly considering that the orthogonal orthotropic quadrangular cone space frame is used later to facilitate air assembly and parallel slip), and the grid plan section is shown in Figure 2.

(2)According to the requirements of JG7-80 “Design and Construction Regulations of Net Frame Structure”:f=u/200=210mm.

(3) In order to meet the roof drainage needs, the conventional upper chord of the grid frame is broken by the old method of finding slope drainage by putting small columns, and the upper and lower chords are taken to slope 3% at the same time to drain naturally to the eaves, and then concentrated by the downpipe to the ground drainage ditch;

(4) The boundary design constraints are only considered longitudinal constraints.

(5) A3 seamless steel pipe is used as the basic rod, the nodes are hot-rolled semi-drum-shaped ball nodes, and the bolts of connectors are 45# steel high-strength bolts.

3 rod calculation and selection

Using the discrete method of programming on the computer calculation, according to the results of the calculation, the rod selection: the largest pipe for Ø159mm × 10mm; the smallest pipe for Ø54mm × 4mm.

4 Node form

(1) The node of the net frame is an important part of the whole net frame design, it is the guarantee of the safety and reliability of the whole net frame structure, and also has a great influence on the cost of the net frame. General nodes of the mesh frame are commonly used hollow ball welding, solid bolt ball connection and flat welding nodes. A comparative analysis of several commonly used nodes was carried out in the design, as shown in Table 1.

|

Node form |

Half drum shaped ball |

Bolt ball

|

Welded hollow ball |

|

Geometric dimension/mm |

Ø250δ20 |

Ø250 |

Ø250δ20 |

|

Quality/kg |

9.0 |

51.4 |

12.4 |

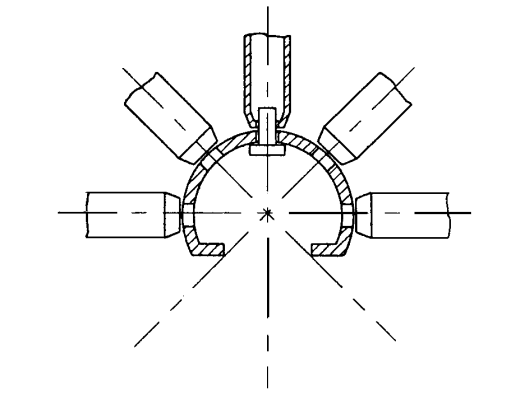

As can be seen from Table 1, the economic indicators of the half-drum ball node are better than those of other nodes. The node profile is shown in Figure3 .

FIG. 3 Node profile

(2) According to the size of the internal force of the bar and construction requirements, the design selected 45# steel special high-strength bolts, the minimum bolt selected M20, the maximum bolt selected M52.

(3) According to the assumption of the perimeter constraint conditions and the displacement of the steel due to the temperature change in Jiaozuo area, the perimeter support is designed to be fixed on one side and simply supported on the other side, and placed on the upper plane of the horizontal tie beam.

5 Mesh frame fabrication and site assembly

5.1 Mesh frame fabrication

Because the net frame is a super static space structure, the overall force performance is good, each rod is the second force rod, single rod member does not bear the role of bending moment, can give full play to the thick-walled steel pipe resistance to tension, pressure capacity

A large span of large area of the production of the network frame need to use dozens of different types of pipe. However, the more varieties chosen, the more the manufacturing process of the manufacturer, long processing cycle, high processing costs, but also not conducive to installation. After careful calculation and the best economic choice, more than 4,000 pipe fittings for the entire network frame selected six specifications of the pipe, namely: 050 × 4, 076 × 4, 0108 × 6, 0127 × 8, 0140 × 10, 0159 × 10, greatly facilitate the factory production, transportation and on-site assembly.

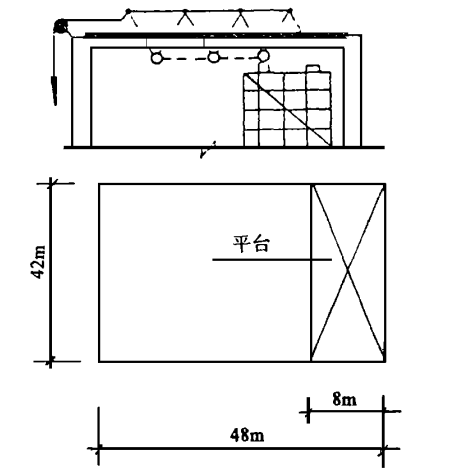

5.2 Mesh frame assembly

Due to the design of bolted connection, it brings to the site construction. Greatly convenient, during construction, according to the site conditions, a 43m×8m platform scaffolding was built, and two groups of hand-pulled inverted connections were used to assemble 1 section and pan 1 section. As shown in Figure 4. In order to reduce the friction between the support and the tie beam when sliding, the steel bar with a through-length of 1 020 was pre-buried in the upper plane of the support tie beam and coated with lubricating oil to make the sliding go smoothly. It took only 15 days to assemble all the grids in place, saving about 30,000 yuan of scaffolding cost and shortening the construction period by 45 days, which was jointly accepted by the Municipal Construction Committee, Municipal Engineering Quality Supervision Station and other relevant departments, fully meeting the design and national specification requirements.

Figure 4 Schematic diagram of the assembly platform

(1) The overall self-weight of the net frame is light, the whole net frame is about 85t, 30% lighter than the same type of net frame, the economic benefits are very significant.

(2) The bulbous ball node is light in weight, simple production process, good structural stress performance, easy to assemble and construct on site, and is a kind of node worth promoting.

(3) On-site assembly and translation, simple equipment, no large lifting equipment, occupy a short time for civil construction, reduce the cost of the whole project.

(4) For the factory production of building components, on-site assembly, played a good role in promoting.