+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

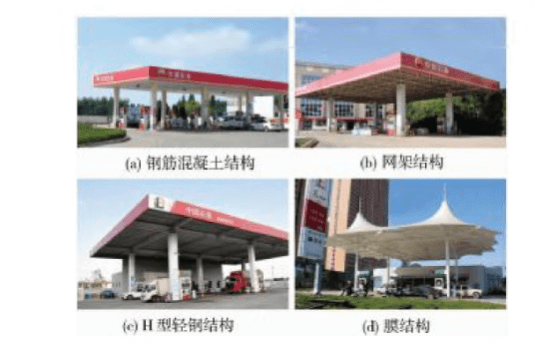

1 Structure type of canopy

Gas station canopy structure usually has a reinforced concrete structure, mesh structure, steel beam and column structure and membrane structure and other types. In fact, the mesh frame and steel beam and column structure belong to the category of steel structure, but the general customary saying in the steel structure refers to the steel beam and column structure.

1.1 Reinforced concrete structure canopy

Reinforced concrete structure canopy has high rigidity and stability, subject to the constraints of historical and objective conditions, this structure type was used in the construction of gas stations in the past [as shown in Figure 1]. However, due to the heavy load of the canopy beam plate itself and the difficulty of achieving a large inter-column span, can not meet the booming gas station industry in the pursuit of large gas station canopy space wide and open, while the reinforced concrete structure has a large impact by weather conditions, long construction cycle, higher cost and other disadvantages, so in the subsequent new gas stations have been less used.

FIG. 1 Application of structure awning in gas station canopy

1.2 Space frame structure canopy

Space frame is a high sub-super-stationary space structure system [as shown in Figure 1(b)] with steel pipe and cast steel ball nodes as the main material, which has the characteristics of large spatial stiffness, good overall performance, uniform force transfer between rods, strong seismic capacity, etc., and can withstand the load from all directions; diverse space shape, can construct various shapes; simple installation, fast construction; can provide a large span of space in the state of point support. This large span, low cost structure type to adapt to the construction of gas stations on the demand for large and medium-sized canopy, thus in the late 20th century in the construction of gas stations has been rapidly promoted, and with the application of color pressure-shaped steel plate as a roofing material, its overall structural performance has also been perfectly presented, a time the design scale of the canopy is increasingly large, and some even up to 2000m2 or more.

1.3 H-type light steel structure canopy

The use of H-light steel structure in gas station canopy started with the application and popularization of the structural type of H-light steel and cold-formed thin-walled steel as load-bearing materials in the domestic industrial plant field. The moment of inertia and bending resistance obtained in the same amount of steel used in the cross-section are also greater, especially for light-load structures of larger spans. Secondly, compared with the lattice steel structure load-bearing system, its structure is simple, convenient in construction and easy in quality control, especially the thickness of the structural layer of load-bearing members has been greatly reduced. This is especially important for the construction of gas station canopies such as Sinopec, CNPC and CNOOC, which have unified image standard requirements [see Figure 1(c)].

1.4 Membrane structure canopy membrane structure

It is a kind of space structure type which is made of various high-strength membrane materials and reinforcing members (steel frame, steel column or steel cable) to generate pre-tensioning stress inside it in a certain way to form a certain space shape as a cover structure and can bear the external load. In membrane structure, the weight of membrane material is only about 1/30 of traditional building material, which can fundamentally overcome the difficulties encountered in traditional structure on large span (unsupported) building and create huge, unobstructed visual space, and has the advantages of free and light shape, simple and easy production, quick installation, flame retardant and energy saving, safe use, etc. Therefore, it is applied in many occasions. Gas stations mostly adopt steel keel frame membrane structure and tensioned membrane structure [as shown in Figure 1(d)]. At present, this kind of light, stretching and small chic landscape shape is used to build small green island gas stations (in the green belt by the city road), which is a better way to solve the problem of difficult refueling in the city due to the rapid increase of vehicles and the increasing tension of land. However, due to the difficulty of forming a unified image effect with other structural canopies, this beautiful looking membrane structure canopy is rarely used in the construction of medium and large gas stations.