+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

3、Insulation cotton

Insulation wool has rock wool, glass fiber and other materials. Insulation wool has excellent thermal insulation performance, convenient construction and installation, remarkable energy-saving effect, and low thermal conductivity. At present, the roof system of domestic steel structure factory buildings mostly adopts: (1) steel wire space frame + aluminum foil insulation cotton + single color board; (2) two-layer color board + insulation cotton.

The following mainly introduces the construction method of steel wire space frame + aluminum foil insulation cotton + single color board roof:

Pull the stainless steel wire or galvanized wire crosswise into a rhombus or rectangular shape, fix it on the purlin with 215 cm long self-tapping nails, lay glass wool felt, the aluminum foil faces the indoor side, perpendicular to the purlin, and leave more space at the eaves on both sides 20cm roll of felt, fixed to the outermost purlins with double-sided tape. Use the reserved 20cm veneer to close the edge of the glass wool. Pay attention to the tension and alignment of the glass wool roll felt, and the tight seams between the rolls. When lap joints are required in the longitudinal direction, the lap joints should be arranged at the purlins. According to engineering needs, in order to avoid the generation of cold bridges, hard insulation materials can be considered on the purlins.

4、Gutter and cornice

According to the structure, the cornice can be divided into three types: the outer drainage gutter cornice, the inner drainage gutter cornice and the free fall gutter. The form of free falling water and external drainage gutter eaves can be preferred. According to the material, there are stainless steel gutters, steel gutters, and color plate gutters. As the main drainage system of the roof, the gutter determines the discharge of rain and snow and the normal use of the building roof.

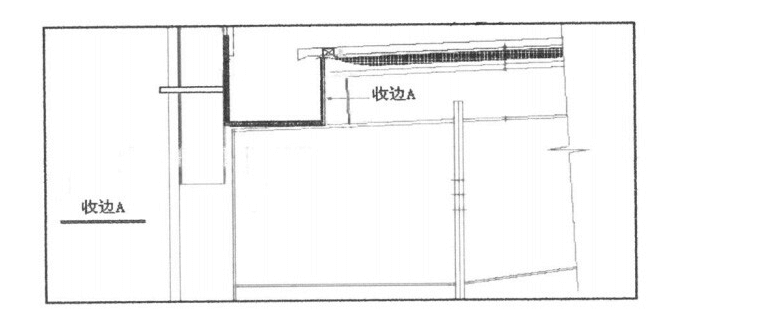

Figure 1 Sketch of Laying thermal insulation foam under the gutter

In cold areas, the temperature difference between indoor and outdoor is large in winter, and condensed water will appear under the inner gutter, so it is required to lay insulation cotton under the gutter, and the method shown in Figure 1 can be used during construction. The insulation cotton is fixed by hanging the purlins of the gutter. At the same time, add an edge (usually color steel plate) to the bottom of the gutter, such as edge A in the picture, which is not only beautiful but also can fix the insulation cotton.

In areas with little rain in the north and where the project does not have high requirements for cornices, free-falling cornices can be used. The cornices are protruded from the wall, and the actual protruding wall surface should not be less than 300mm. If the color board on the wall and roof is a single board, the saw tooth-shaped gap between the wall board and the roof board is sealed by a special board-type water retaining member. When the slope of the roof is less than 1/10, the edge of the trough of the roof panel should be bent downward by 5-10 mm with clamps as dripping water.

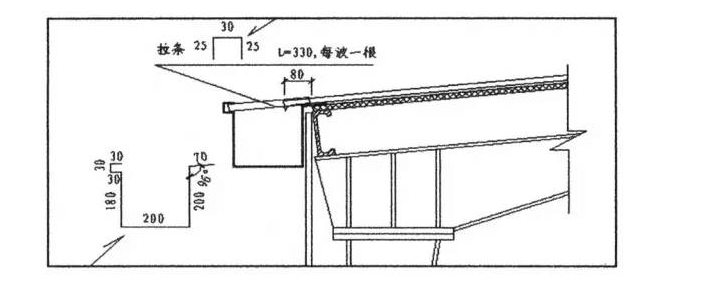

Figure 2. Cornice of outer drainage gutter

The eaves of the external drainage gutter are also widely used in engineering because of their good leak resistance and low cost. The outer drainage eaves and gutters mostly use color plate gutters. During the construction, the color board gutter does not need structural components to support it. The ditch wall can be directly close to the outer wall panel. The sections of the gutter are overlapped with each other, connected by rivets and sealed with sealant. The method shown in Figure 2 can be used in the project.

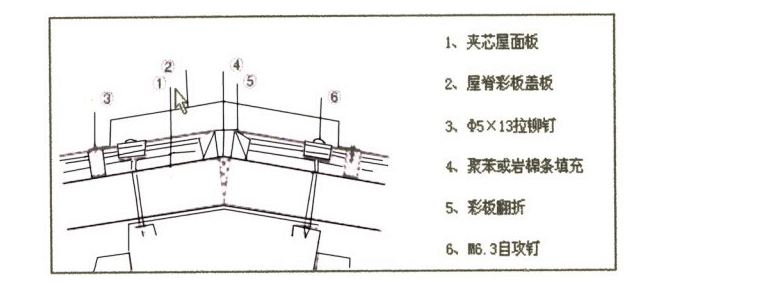

Figure 3 edge covering and flashing

5、Edge wrapping and flooding

Edge wrapping and flashing not only outline the lines of the building and affect the aesthetics of the building, but also structurally connect the building into a whole, preventing wind and rain, making the building stronger and more durable. See Figure 3 for details.

6、Summary and conclusion

Light steel structure has been widely used in factories, small exhibition halls and office buildings due to its characteristics of less steel consumption, short installation and design time, and high degree of industrial production. Its enclosure system often adopts color steel plates. It is of great practical significance to study and summarize the design and construction experience of color steel plate maintenance systems, and to propose economical and reasonable node structures and construction schemes.

For the outer building-style floor panels, the concealed buckle-type color steel plate structure should be used first, which can avoid the self-tapping screws being sheared due to temperature difference deformation, and at the same time avoid the temperature deformation and wind load vibration of the exposed self-tapping screws in rainy areas and typhoon areas 1. The aging of the rubber pad will cause the corrosion and water leakage of the board.

During the design and construction of the day lighting board, attention should be paid to its thermal expansion and contraction. There must be a cover plate at the connection between the lighting board and the self-tapping screws. At the same time, pay attention to the difference between it and the color steel plate. The lighting board should be processed with pre-punched holes (8mm holes are suitable).

In order to avoid the generation of cold bridges, it can be considered to pad hard insulation composite boards on the purlins.

In areas with little rain in the north and the project does not have high requirements for cornices, it is recommended to use free-falling cornices. It has good leakage resistance and low cost, and is widely used in engineering.