+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

In recent years, the environmental protection situation is getting tighter and tighter, from the central government to the local level, and environmental protection standards are constantly improving. Environmental protection has become an increasingly important issue in this day and age, and has attracted widespread attention around the world. With the rapid development of China’s national economy and the strengthening of the national environmental protection policy, the country’s requirements for environmental protection are getting higher and higher, especially the control of environmental pollution in the energy industry is more strict. In order to reduce the pollution of coal storage yard to the environment, improve the environment around the coal storage yard and enhance the ambient air quality, comprehensive treatment of coal storage yard is carried out to meet the environmental protection requirements. After sealing, it can reduce wind and rain damage, slow down the oxidation of coal pile in summer and reduce the loss, and also improve the environment and hygiene of the surrounding area and enhance the environmental protection image of the company.

1、Project Overview

Inner Mongolia Dengkou Jinniu Coal Power Co., Ltd. has a total height of 17 meters of wind and dust suppression net built around the coal yard, supporting a bucket wheel machine and coal unloading ditch on coal. This transformation of coal shed closure using double-layer bolts ball reticulated shell structure using square quadrangular cone structure, reticulated shell support method for the inner string support, inner string support structure can be more effective use of internal space of the structure, the length is 256 meters, the span is 119.5 meters, the structure arch height: 40.9 meters, reinforced concrete coal retaining wall height 2.5 meters, structure around the support column for concrete L-shaped column, roof and both sides of the mountain wall for single-layer color plate The structure is free falling roof system, positively put quadrangular cone, multi-point support, the construction area of coal washing shed is 30,592 square meters, divided into two areas of A and B construction, a construction joint, the node form is bolt ball, the roof purlins use galvanized C section steel, the roof color plate use galvanized color plate, the lower chord of the space frame has maintenance horse path.

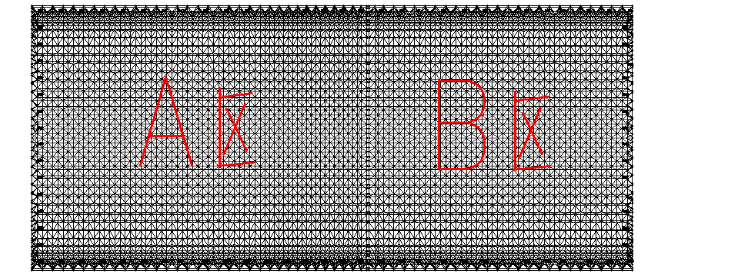

The space frame installation partition is installed as follows Figure 1:

Figure 1 Space frame installation partition plan layout

1.1、Construction site preparation

(1) The original plan was to start the project on April 1, 2020. Due to the delay in the start date, the space frame installation plan was determined to be a bulk installation plan in order to ensure the completion of the project as scheduled.

(2) The technical department of the company organizes production, engineering and technical personnel to review the construction drawings and carry out the secondary decomposition design of the production process, node deepening and material selection according to the requirements of the construction drawings.

(3) Materials, components (accessories), machinery and equipment are the material basis to ensure smooth construction, and the preparation of these materials must be completed before the start of the project. According to the demand plan of various materials, implement the sources of goods, install transportation and prepare them respectively to meet the requirements of continuous construction.

(4) The construction team organization adheres to the principle of reasonable and lean, and at the same time should be determined according to the labor force need plan formulated by the construction organization design. When the installation team is organized to enter the site, education on safety, fire prevention and civilized construction should be conducted, and various management systems of the site should be established and improved, and the personnel of each post should be assessed according to the various guarantee measures formulated by the organization design.

(5) Installation and commissioning of construction machinery. According to the construction machinery needs, arrange the plan, organize the construction machinery into the field, and place the construction machinery in the specified location or warehouse. For fixed machinery to be in place, shed, connect power, maintenance and commissioning. All construction machinery must be inspected and test run before starting work.

1.2、Material preparation

For the bolted ball node space frame, the processing of the rods is the focus of the entire space frame structure processing; the quality and accuracy of the processing by the rods directly affects the assembly and installation of the space frame site; the rods are either too long or too short for the installation of the space frame.

(1) Set up a quality management group, specifically responsible for quality acceptance and control.

(2) According to the construction plan of foundation and retaining wall, work with contractors to arrange the supply plan and production schedule of materials such as grids, purlins and color steel plates. According to the plan node, rush to the steel processing plant to supervise the quality situation and track the arrival situation, etc. Ensure that the process is carried out smoothly to avoid the work schedule being affected by the nesting situation.

(3) Summarize the schematic diagram, numbering, production process characteristics, and finished product acceptance standards of steel components into a table and submit it to the quality management team for review and acceptance in accordance with quality standards.

(4) Unqualified components are scrapped on the spot, and a unified storage location is specified to avoid confusion.