+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

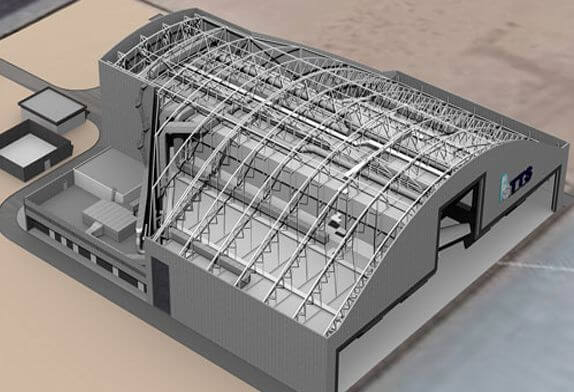

1 Maintenance Hangar Project Overview

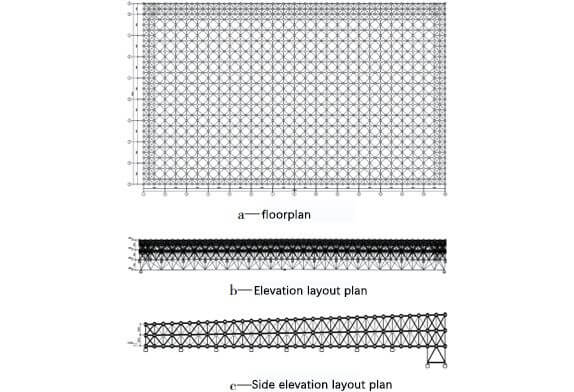

The structural form of the international airport maintenance hangar building is a steel-concrete column and space frame structure. The space frame size is 83.3m × 138.6m, section size of the steel-concrete column is 2.2m × 1.6m, 1.3m ×1 m, the building height is 34.85m, and the total construction area is 11 545.38 square meters. The structure of the space frame is inclined to put four Angle cones, the opening of the gate is strengthened by four side trusses, the maximum height of the space frame is 13.2m, and the connecting nodes are welded ball nodes supported by three sides. The top elevation of the steel reinforced concrete column is 34.85m except for the top elevation of the column at the gate, which is 24.9m. The layout of the space frame structure is shown in Figure 1. The installation of the main space frame structure adopts the secondary overall lifting technology.

space frame layout plan

2 Characteristics and difficulties of the project

2.1 Engineering Features

There are about 10,365 rods and 1,002 tons in the space frame truss project of the maintenance building of the international airport. The welding balls are about 2,609 pieces, the mass is 205 T, and the total mass of the space frame is 1,400 T.

The space frame installation of the maintenance building of the international airport adopts the secondary overall lifting technology. The gate truss and the central space frame are joined together on the ground. The central space frame is first raised to 5.0m elevation and welded together with the gate truss as a whole before the second lifting. The pipeline in the space frame, maintenance lane, roof purlin, etc., shall be installed together with the space frame, and other equipment shall be installed after the space frame is raised to a certain height. In order to ensure the stability and safety of the lifting process of structural units, according to the characteristics of the space frame steel structure, the simultaneous lifting and unloading position control strategy of “oil pressure balance at the lifting point, structural attitude adjustment, displacement synchronous control, and hierarchical unloading position” is proposed.

2.2 Key and difficult points of the project

(1) Large span (maximum span 138.6 m), large mass (1400 T), the conventional lifting method is difficult. The conventional piece-lifting construction method has poor safety and long construction period.

(2) there are many types of space frame rods (the number of rods is more than 10,000, and the number of balls is more than 2,000), and the welding quantity is large. Hollow balls, pipes, and balls, pipes butt weld welding quality requirements are high, are the first-grade weld.

(3) Monitoring is difficult. The number of rods and bolt balls, deformation in the construction process is complex, difficult to monitor; Hollow balls, pipes and balls, pipe butt weld requirements are the first-grade weld, for welding quality of weld quality detection is difficult; It is difficult to detect synchronicity during installation.

3 Space frame construction

3.1 Construction scheme selection

Project construction methods have high bulk method, block installation method, high slip method, the integral hoisting method and integral lifting method, integrally jack-up method and other methods, the construction of engineering application of the method has high dispersion method, block installation method, and integral lifting method, by comparing various solutions (table 1), finally choose the overall approach to the construction of ascension.

|

construction scheme |

Advantages and disadvantages |

|

High altitude bulk method |

This requires building a 280,000 m3 high-altitude support frame, which has a relatively long construction period. Besides, high-altitude assembly and high-altitude welding are difficult to construct, and the technical and economic indicators are poor, resulting in great safety risks. |

|

Section mounting method |

When assembling in sections, two cranes of more than 350 t are used for lifting. The synchronization of the operation of the two cranes is poor, and it is easy to lead to an overload of the crane when the load is biased to one side. The crane model is larger, the service time is more scattered, and is not cost-effective. When assembling in sections, there are many post-assembling segments at high altitudes, which is not easy to control safely. |

|

Integral lifting method |

The space frame is assembled on the ground, which is fast and easy to operate. The hoisting machinery used is smaller and the cost is lower. The ground assembly is of high safety, the synchronization of the overall lifting, the load-bearing of flexible steel strand, and the self-locking of the hoist have the advantages of safety and reliability. |

3.2 space frame construction process

The assembling process of the space frame is divided into three parts: the gate truss, the middle truss, and the rear truss, in which the construction of equipment such as the bridle path and pipeline is installed synchronously with the space frame. First, the middle space frame and the gate truss were assembled on the ground, and one post-assembling segment was set between them, and two post-assembling segments were set outside. The installation of the space frame adopts hydraulic synchronous lifting technology, and two times to lift: after the completion of the gate truss assembly, the temporary lifting frame is used to lift the lower chord of the central space frame to 5.0m elevation, and the connection with the gate truss is realized through the assembly of a post-assembling segment so that the space frame forms a whole; After assembling, carry out the second lifting, lifting height directly reach the design elevation, and then carry out the installation of the second post-assembling segment.

The construction of space frame structure in the international airport maintenance building provides the following experience for similar projects:

(1) in the span of a large, rod system, complex form of roof construction, the need for the characteristics of the space frame to select the right lifting point or support point, in the most reasonable place of lifting, can reduce the impact of lifting process on the structure. (2) Attention should be paid to real-time monitoring in the construction process of the overall lifting of the space frame. Any deviation of the superstructure will have an impact on the subsequent construction process, which requires real-time monitoring and real-time correction.