+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

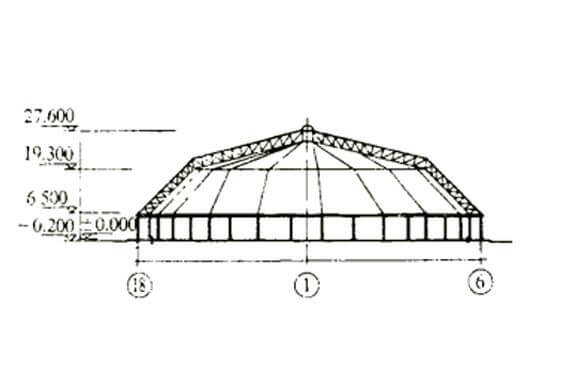

The pre-homogenized limestone storage shed of Shuangyang Cement Plant is a steel structure with a large span dome. The structural plane projection is 18-sided (generally called round storehouse), with a diameter of 86. 616m and a central vector height of 27.6m. It is the largest dome steel structure with the largest span that has been completed in China.

For the first time in the design of this project, the installation method of steel tube structure without joint plate truss and torsional shear high-strength bolt splicing is adopted. The technical and economic index of the project is advanced, and the calculated steel quantity index is 49kg/m2. Due to the novel structure, the design of the use of new technology, new technology, the structure of the production and installation of high requirements, its production accuracy and installation deviation requirements have been higher than the current state of construction and acceptance of the provisions.

For the first time in the design of this project, the installation method of steel tube structure without joint plate truss and torsional shear high-strength bolt splicing is adopted. The technical and economic index of the project is advanced, and the calculated steel quantity index is 49kg/m2. Due to the novel structure, the design of the use of new technology, new technology, the structure of the production and installation of high requirements, its production accuracy and installation deviation requirements have been higher than the current state of construction and acceptance of the provisions.

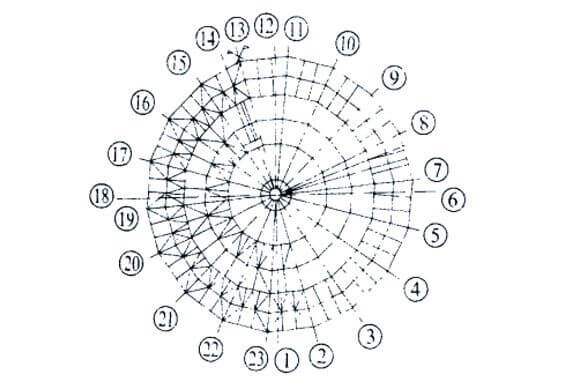

Because Xiangyang cement plant is located in a remote mountainous area, the components are overweight and long, and long-distance shipment is inconvenient, the site production scheme is determined through scheme demonstration and cost calculation. Officially lifting, 8 sets of crane is in 2-3 axis respectively, 9-10 shaft lifting at the same time, the left and right sides of the triangle element to reserve position accurately in place after the first triangle unit cell and the surrounding ring beam coupling, to join the upper center steel GJ5 cooperate with high strength bolts in an early twist, then remove 2-3 axis and 9-10 of the bottom of shaft 4 cranes to 17-19 axis on both sides, will be arranged After the connection of the segment assembled triangular units, the lifting is in place. After the bolts are fitted, the three triangular units are finished at the same time. Two theodolites were used for simultaneous detection on the ground to ensure that the axial verticality and horizontal displacement of GJ5 were controlled within the allowable range during the final protection. Thus, the lifting of three units in the first round was completed. The lifting of trans-triangle units was completed. After hoisting of 9 triangular units, hoisting of 9 empty span brackets and support high-strength bolts shall be carried out in the same sequence as above, but final protection shall not be carried out. After all, bolts are fitted, final twisting shall be carried out from inside to outside.

Steel frame assembling and hoisting order

in recent years, large-span steel structure dome with its advanced technical and economic indicators, novel and unique structure show the broad prospects for development of this project adopts the construction method to overcome the disadvantages of the traditional hoisting method to determine the solution is to meet good structure stability, low cost, operational principle, a reliable technical and economic argumentation, select the best structure lifting scheme, namely 120° Angle lifting method, lifting stability is very good, to ensure the overall stability and safety of steel structure, minimize the amount of aerial work. In the tightening of high strength bolt, the manual heavy-weight-moving hand is used for primary and final twisting, and good technical and economic results are obtained.