+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1.1 The quality control of the bolt ball space frame

The bolt ball is composed of bolts, pipe sleeves, pins, cone heads or sealing plates, and is connected by high-strength bolt balls with steel bolts to form a space truss structure, which carries a load of baseball space frame. Any quality problem component will endanger the overall safety structure; this should be a good quality component.

Strict quality space frame components should be done before assembly to eliminate unqualified components to ensure the quality of the most important part of the project space frame structure. When the space frame components enter the site, they must check the delivery certificate, make a good entry and acceptance records, and conduct sampling inspections between each group in accordance with the regulations. In addition, rod inspection and testing can not be ignored.

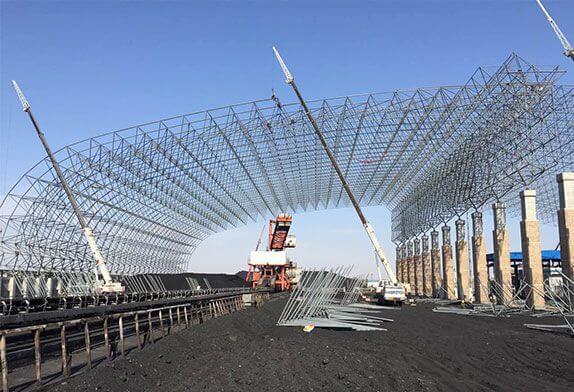

1.2 Quality control of space frame assembly and hoisting

In order to ensure the correctness of the formal construction, pre-assembly work is required. During pre-assembly, the site should be leveled and compacted, and the samples should be accurately staked out. The specifications of the bolt ball and the correct position of the compression member should be carefully compared with the design model of the drawing to prevent errors in the position of the tension and compression members. When assembling, the lower string should be assembled first, and then the elevation and axis of the lower string should be corrected and tightened and positioned, and then the web rod connection and the upper string assembly should be performed. During the assembly, the tightening should be prevented from being too loose or too tight to avoid the resulting Assemble residual stress. For decorative ceilings, fire-fighting pipelines, horse tracks, heavy equipment and temporary construction erection, bolts are required to be suspended on the ball joints (it should be noted that all suspended objects need to be designed and calculated, and the weight and quantity cannot be increased randomly), Welding connection is not allowed. It is very dangerous to prevent the weight of the equipment from hanging directly on the rods, especially the heavy equipment suspended in the middle of the pressure rod.

If the equipment is suspended in the middle of the rod, it is equivalent to adding a concentrated force in the middle of the rod span. The heavier the corresponding concentrated force, the greater the damage to the rod, which may cause bending damage, causing the space frame to lose stability and cause overall collapse and damage.