+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

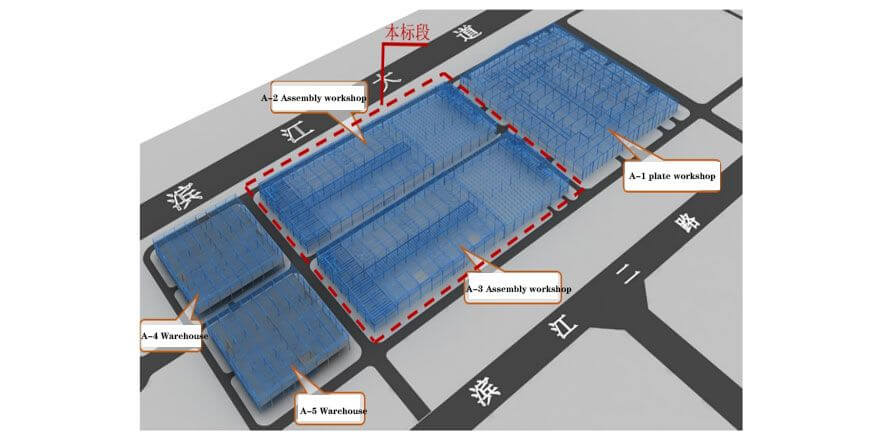

Total construction area: 50380m², of which A-2: 24782m², A-3: 25598m². The number of floors of the main body structure is single-story, and the battery warehouse and auxiliary buildings in the workshop are two-story reinforced concrete structures. The main steel structure is in the form of a single-layer truss + space frame + frame composite structure, and the overall distribution of the steel structure is shown below.

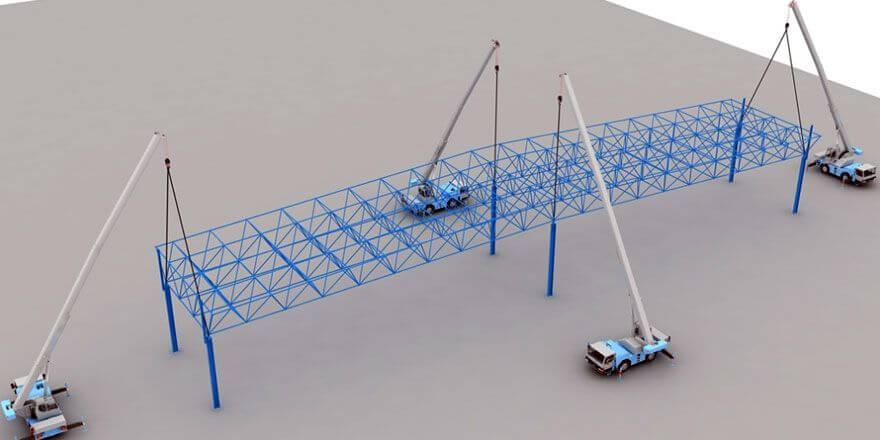

Prefabricated steel structure hoisting. The steel structure of this battery warehouse building project is a single-layer steel structure with a large span and column spacing. Before the structure is installed, it is very easy to cause overall instability and overall collapse. Therefore, the choice of steel structure hoisting scheme is Key consideration for this prefabricated steel frame battery warehouse project

1. Arrange a reasonable installation sequence for the steel structure. The installation of the rigid frame starts with the distance between the supporting columns so that the structure can form a space stability system as soon as possible during installation, and then expand the installation based on the stability system to ensure that the overall structure is always stable during the installation process. stable system;

1. Arrange a reasonable installation sequence for the steel structure. The installation of the rigid frame starts with the distance between the supporting columns so that the structure can form a space stability system as soon as possible during installation, and then expand the installation based on the stability system to ensure that the overall structure is always stable during the installation process. stable system;

2. After the steel column is hoisted into place temporarily, it is temporarily fixed with a cable wind rope; in order to prevent the steel beam from being too deformed and unstable outside the plane, the roof truss beam is hoisted with the help of a horizontal hanging beam (commonly known as an iron pole), the first roof truss beam After hoisting, fix it with cable wind rope;

3. Immediately after hoisting a roof truss beam, install tie rods, supports, and some purlins with the previous roof truss beam, and take lateral support measures in time to prevent component instability.

The roof of this project has a long single slope, the enclosure system is a double-layer slab structure, and the roof bottom is hidden (that is, the bottom board under the purlins), the quality of the node treatment is directly related to the appearance and waterproof performance of the building, therefore, the envelope structure Installation quality control is the focus of this project.

1. The roof panels are rolled and formed on-site to avoid longitudinal joints of the panels, and the flashing panels are made according to a length of 8m.

For installation, use special waterproof glue on the overlapping joints of the flashing boards to prevent leakage at the overlapping joints;

2. Strictly control the verticality of the reference plate in the plate installation project, and do a good job of re-inspection and correction at any time;

3. When installing the bottom plate, make a light-duty hanging cage, hang the cage on the purlins, and move the hanging cage with the installation progress of the bottom plate;

4.The details and corners of the profiled steel plate are treated according to the atlas and combined with actual experience to optimize the treatment to ensure that the nodes are beautiful and

It has a good waterproof effect.