+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

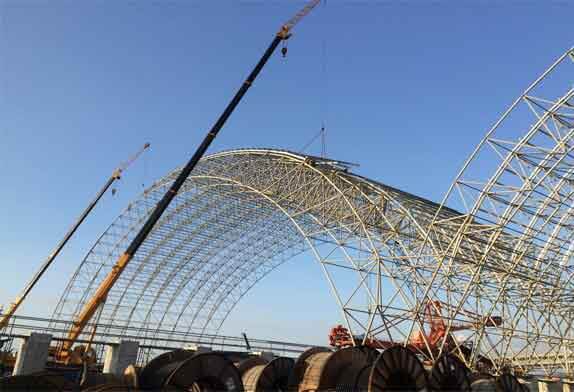

The space frame arch roof structure of the coal storage bunker in the power plant has a length of 126m, a span of 103m and a height of 47m, a surface area of about 33000m², and the lower concrete retaining wall height of 3M, single color plate enclosure, steel volume of about 700T.

2.1 Construction process flow construction preparation → measurement and layout → support installation → starting unit ground segment assembly → starting unit aerial docking → small unit high-altitude bulk → main body acceptance.

2.2 Support tower installation

2.2.1 In order to facilitate recycling, the supporting tower should be made into a tool-type movable frame connected by bolts.

2.2.2 According to the height and bearing conditions of the support, simple caps can be made of road logs and steel plates below 15 meters, integral steel caps can be made from 15-30 meters, and concrete caps can be made above 30 meters.

2.2.3 Install the supporting tower according to the design position and elevation, and fix it firmly with the cable wind rope. The top of the support tower should be a non-slip fulcrum with adjustable height to ensure reliable support for the lower string ball of the space frame.

2.3 Installation of starting unit

2.3.1 The spaceframe starting unit is to firstly form a space structure unit with a certain rigidity to bear the construction load. In order to reduce the accumulation of errors, it is generally selected in the middle of the entire grid shell with a width of 4 to 5 grids.

2.3.2 The starting unit is generally divided into three blocks A, B and C when assembled. First, the assembly is completed on the ground near the installation location. Since the blocks are arched during assembly, support should be done to prevent deformation, and the blocks should be assembled with finishing paint for the last time before hoisting.

2.3.3 Installation of Sections A and B

Lift the assembled sections A and B to the design position first, with one end fixed on the support, and the other end temporarily fixed on the already installed support tower.

2.3.4 Installation of Section C

After the installation and adjustment of Sections A and B are completed, use four cranes to lift and install Section C, and connect with Sections A and B in the air to complete the overall closing of the starting unit.

2.3.5 When docking in the air, the bolts between the sections must be fastened in place to form a whole, and finally closed into a stable arch structure. If there is an error in closing, the inverse chain uniform tension adjustment is used to eliminate the error to complete the closing, and then the parameters of the closed arch structure are inspected, and the next process can be carried out only after meeting the requirements.

2.4.1 After completing the closing of the space frame, it will enter the high-altitude bulk loading stage. The crane is used for cantilever installation on both sides at the same time. It is required that the cantilever installation must be closed in a circle, and the support should be fixed according to the design requirements to ensure the overall stiffness of the reticulated shell.

2.4.2 In order to speed up the installation progress, the high-altitude bulk loading of the space frame adopts the method of advancing from the middle of the reticulated shell to both ends along the length direction. During high-altitude bulk loading, firstly fix the support according to the design position, and then install it from bottom to top and close it one by one, gradually, extending towards both ends until all is done.

2.4.3 In the case of high-altitude bulk loading, the installers can be divided into two parts for each working face, one part is assembled with small ground units, and the other part is installed at high altitude. The installation procedure is: first, the ground assembly personnel shall install the space frameto be installed on the ground according to the requirements of the drawings. Assemble into small units, use a crane to hoist the small unit to the corresponding position of the installed space frame in the air, and complete the connection between the small unit and the grid by high-altitude operators.

2.4.4 Ground assembly of small units

The ground unit is also called a pyramid, that is, a small unit composed of a node ball and ~5 rods on the ground, and the small unit is divided into a lower chord unit and an upper chord unit. When assembling on the ground, all rods should be installed tightly in place.

2.4.5 Installation of small units

Tie three tethers to the ball end and the upper (lower) chord respectively, (see above) the length of the three tethers should be controlled so that the hoisted tripod is close to the actual installation position in the air. The deflection angle should not be too large, so as to facilitate the response of high-altitude installers. Use a crane to lift the small unit to the installation location. After receiving the corresponding installation rod, the installer will connect the high-strength bolt with the bolt ball hole. When installing the bute-frame. The high-strength bolts should be tightened to the support, and no gaps visible with the naked eye are allowed on the contact surface of the unthreaded nut. During the initial connection, three to five buckles should be screwed in first. After the ball is installed, fasten the high-strength studs in place together to avoid one or two high-strength bolts being tightened first, which will make it difficult for other high-strength bolts to be installed in place.

2.4.6 Large span coal bunker arched steel roof building space frame in the process of high altitude assembly due to the dead weight of the space frame will produce a certain degree of deflection, if the deflection is too large, it will affect the normal installation and construction safety, to solve this problem generally adopt scaffolding or installation support tower, with a thousand JTS top support, the installed mesh shell deflection control within the allowable range.