+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

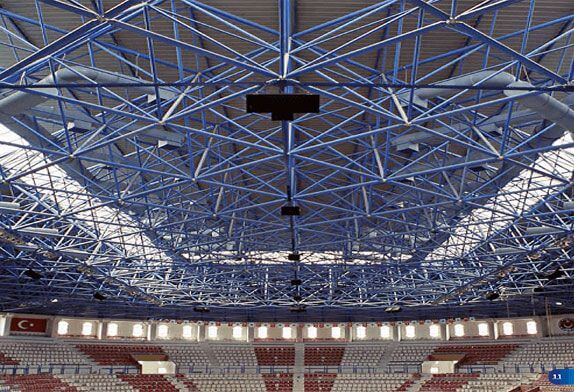

Steel structure building in our country has a certain proportion in the building, especially big frame transportation building, industrial building, tall building, gymnasium, exhibition hall, and so on. Under high fire temperatures, the steel structure without fire protection will collapse in about 15 minutes, causing significant damage. In order to achieve the design fire resistance limit of steel structures, GB51249-2017 “Technical Specification for fire prevention in Building Steel Structures” stipulates the fire protection measures that can be adopted by steel structures, including spraying fire retarding coatings, coating fire boards, coating flexible felt materials, and outsourcing concrete. Steel structure fire protection needs to maintain good physical and chemical properties for a long time in order to play a protective role in the fire. The durability of the coated fireproof board is good, and it is currently applied in the prefabricated steel structure building. The disadvantage is the high cost and the building area are reduced. Daily steel structure fire protection detection and tracking services found that many engineering designs for steel structure fire protection coating, painting early, coating appearance and physical and chemical properties are good, as time goes by, cracks, falling off, and other phenomena, serious impact on the steel structure fire limit, some projects within half a year coating is such a situation, or even completely lose the basic function of fire protection.

The coating shedding of steel beam of an office building

Steel structure building is being promoted massively in our country, and a lot of problems exist in the use of fire protection all the time, which should be solved.

1.1 The design and construction of the steel structures must be based on the drawings issued by the design institute. Some steel structure buildings pass special fire protection design in the design stage, and steel members above 8m do not carry out fire protection. At present, there are no relevant cases of fire collapse of steel structure buildings through risk assessment using this kind of method. At present, there is no standard for this kind of design. There are also some problems in the selection of fire protection methods for steel structures. Some buildings such as Beijing Universal Studios Theme Park, National Stadium, Olympic Park multi-functional studio tower, Beijing Fengtai railway station and other steel structure building steel beam, due to aesthetic, time and other requirements, the design description of 100% specified related components using expansion steel structure fireproofing, this kind of coating thickness is generally less than 5mm, After the fire expansion, the thickness of the dense carbon layer is more than 5 times the original one, which protects the steel structure. However, there are many fake and inferior products on the market, and there is the possibility of failure of fire protection when used for a long time. According to GB14907-2018 “Steel structure fireproofing”, expansive steel structure fireproofing can be divided into two categories, water-based and solvent-based steel structure fireproofing. Among them, water-based fireproof coating often peels off within two days of construction due to weather reasons; In the application process of solvent steel structure coatings, it is difficult to meet the requirements of the limit of harmful substances in JG/T415-2013 “Limits and detection methods of harmful substances in Architectural fireproofing Coatings”. Designating this kind of paint for protection at the time of design is not only difficult to meet the requirements of the above line, but also poses a huge risk to the fire safety of steel structure buildings for long-term use.

1.2 Fire protection materials do not meet the standard requirements of steel structure fire protection engineering application is increasingly widespread, and unqualified materialand construction phenomena are Some fireproof materials enterprises develop and produce high-quality materials. Enterprises obtain relevant fire resistance limit reports through system certification, but the price is higher. Cheap and high-quality materials are used in the actual project to reduce costs and affect the quality of the project. In particular, some construction units or individuals attached to the qualification use very low prices to bid, the use of fake and shoddy products in the project, the source of goods is not from the brand manufacturers, greatly reducing the fire safety performance of steel components. In engineering construction, the thickness of fireproofing coating is insufficient, partial leakage is applied, the fireproofing board is shoddy, and there are problems in the tightness of the corner position and the connection position of the component.

1.3 The inspection personnel of the institution do not meet the regulatory requirements in their work.

Some inspectors think that steel structure protection detection once and for all, in the detection work of joint construction, supervision unit fraud. Steel structure fire protection testing personnel do not need professional qualifications for steel structure, the type of steel structure members, fire limit requirements can not be clearly grasp. It is not uncommon for subcontracted construction units to entrust testing institutions to carry out engineering testing, which violates relevant regulations. The testing unit shall issue a qualified testing report for projects with insufficient thickness of non-expansive coating and no expansive coating effect. A project construction unit entrusts a third party organization to conduct engineering testing and obtains a qualified report with a thickness of 6mm. However, related problems were found after audit, and the owner re-entrusts another testing unit, and the testing result is less than 2mm, which cannot meet the design requirements.

1.4 Fire protection of steel structure is ignored in the acceptance link.

Beijing, Hebei, Shandong and other places have long implemented the supervision and acceptance process of steel structure fire engineering. Shanghai has incorporated the quality of fire spray engineering into the scope of fire control acceptance of steel structure construction engineering completion since May 2008, and implemented program inspection and quality random check. Some provinces and cities in our country lack the inspection of the project at present.

1.5 Lack of management and maintenance responsibility system in project use.

The project is accepted in accordance with relevant standards, and there should be no serious quality problems in the short term. Projects that should be used for five to ten years often have serious quality problems within one or two years and must be rebuilt, which greatly increases the social cost. The reason is that the late maintenance management and quality identification of fire protection projects lack of standards that can be based on, can not form closed-loop supervision, and no construction personnel and other relevant responsible persons bear the due maintenance costs of the project. After a fire protection project is put into use, the large piece of coating falls off and affects the normal work. The coating quality problems that appear in half a year should be borne by the construction and construction units, but the relevant personnel shirk responsibility, can only be borne by the owner all losses, pay the maintenance costs, and carry out maintenance and construction and testing of the building.

1.6 There is a lack of databases for the long-term use of steel structure buildings in different environments.

Under different environmental conditions such as indoor, outdoor, petrochemical, and so on, the durability of steel structure protection materials is different. In civil buildings, some steel components are in humid environments, equipment rooms, and other environments, and the durability response of the coating is also different. Fire-fighting facilities, other building components, materials, and other relevant national standards for the use of the corresponding materials, identification, maintenance, etc., such as the use of building foundation, from the design, construction, acceptance, and identification of existing projects have clear standards, to ensure the basic state of use. The designed service life of steel structure reinforcement rubber is mandatory to be no less than 50 years0 “Civil building energy saving regulations” clearly stipulate that under normal conditions of use, the minimum warranty period of insulation engineering is 5 years. However, there is no service life of steel structure fire protection materials. At present, in the process of various building fire risk assessments, the content and system of steel structure fire protection evaluation lack integrity and scientificity. Once there is a problem in the existing untested project, it is difficult to trace back the inspection and acceptance report and the violation of engineering construction supervision, and it is difficult to determine the responsibility period and the responsible person of the inferior project.

The above six types of problems belong to the direction of technology or management, involving design, construction, testing, acceptance and other links, and different countermeasures should be adopted according to different situations.

2.1 Choose protection measures with good durability in the design phase

Some steel structure buildings which do not do fire protection, should summarize the relevant cases, set up relevant standards for tall buildings steel structure fire design clearly, can make a more clear judgment of the relationship between the existence of fire hazards and building safety. In view of the improper selection of steel structure fire protection design, in the early stage of steel structure engineering design, should consider the choice of fire protection mode, designers should recommend good durability of fire protection measures, steel structure engineering design service life is generally more than 50 years, hidden steel structure fire protection measures failure, it is difficult to maintain; In addition, during the maintenance of steel structure buildings in use, equipment shutdown and personnel evacuation are generally required, resulting in large losses.

Therefore, in the design stage of steel structure buildings, in addition to strictly implementing the relevant provisions of GB51249-2017, when designing fire protection measures, the durability of protection measures in the long-term use of steel structure buildings should also be considered to reduce later maintenance expenditures. When choosing the coating for fire protection, it is recommended to choose high-quality non-expansion steel structure fireproofing and water-based fireproofing with good durability. In harsh outdoor environment and petrochemical field, it is recommended to use epoxy fireproofing for expanded steel structures. In T/CECS24-2020 “Technical Regulations for the application of fire retardant coatings for Steel structures”, it is recommended that non-expansive and epoxy coatings be used for components with fire resistance limits greater than 1.5h.

These two kinds of coatings have good durability and can better meet the requirements of steel structure architectural design. Some high-quality coatings have more than 20 years of engineering practical application experience in foreign countries, which can maintain a complete state and truly play the role of fire protection.

2.2 Commissioning independent third-party testing units to carry out construction phase testing Chinese laws and regulations stipulate that construction units should take primary responsibility for project quality. Specific to actual projects, there should be perfect standards and regulations to supervise the construction process, supervise the construction personnel to strictly control the purchase channels, and strictly implement the construction methods stipulated by manufacturers and standards. The project can be managed through the supervision of the construction process by a third-party testing unit.

2.3 Improve the requirements for testing personnel and continue to improve the testing methods

Our country at present does not have the qualification requirements for steel structure fire protection engineering testing personnel, but steel structure fire protection engineering testing personnel should have the basic post ability, such as clearly distinguish the name, position, fire resistance limit requirements of steel structure related components. The written record of on-site inspection has been specified in the relevant testing requirements, but there is no requirement for video recording at present. Some steel structures belong to hidden works, and complete video data records should be recorded before concealment to prevent fraudulent paper records. Designers can cooperate with construction and testing units to spray different color blocks of red, yellow and blue about 2cm for steel members with different fire resistance limit requirements of 3,2.5 and 2h, especially for key components of special load-bearing parts. This method has been used in related engineering testing and achieved good results.

2.4 Inspection report shall be examined in the acceptance of steel structure project.

During the acceptance inspection and on-site supervision of steel structure engineering, the fire limit test report and factory qualification report of steel structure fire protection materials should be checked. Combined with the design documents, the fire protection mode of steel structure members should be confirmed, including the type and thickness of paint, and the construction mode of fire protection board keel, screws and other supporting fixed parts. The focus is on the project inspection report, which shows that the project has been tested and identified by an independent third-party inspection agency and that the quality is guaranteed.

2.5 Compile maintenance and construction standards for steel structure engineering.

The problem of management and maintenance in the use of the project can be solved through the preparation of relevant standards so that the fire protection identification and maintenance have rules to follow. Engineering maintenance also needs to formulate corresponding measures, such as different coatings in various circumstances, you can choose to re-paint on the original base, or the original paint will be removed, re-paint anti-rust paint, and fireproof paint. Among them, the construction of hidden works is relatively difficult. There should be standards for maintenance, testing, and construction, and the organization, implementation, and safety measures of engineering projects should be stipulated. The testing unit shall intervene in the maintenance and construction phase to ensure the quality of the project. When an office building is repaired, because the office is in a separate state, the construction personnel of each floor office are different, and the construction quality is different. According to the field situation, the third-party testing unit detects the protective layer according to the office separation in the construction stage, so as to ensure the quality of the project.

2.6 Improve the user management and maintenance means of steel structure engineering.

It is necessary to record the fire protection situation through the site investigation of the existing steel structure building, establish the steel structure protection database, record and evaluate the fire protection measures of the existing building steel structure, and determine the grade and division to determine whether the fire protection of the building steel members is effective. The relevant standard specifies the corresponding service life, which is an important basis for ensuring the fire safety of steel structure buildings.