+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

The total construction area of an Olympic training hub is 71,166 square meters, of which: the construction area of the training building is 31,635 square meters (23,371 square meters above ground, 8,264 square meters underground), and the construction area of the comprehensive building is 39,531 square meters (34,216 square meters above ground, 5,305 square meters underground).

The pursuit of maximizing activity space has always been an important part of human construction history, which has created many excellent long-span buildings. At the same time, because of the beautiful shape of the long-span space structure, the shaping of the internal space and appearance of the building has been sought after by many architects. With the rapid development of our national economy, the demand for sports venues is increasing day by day. The construction of sports venues is hot like tea all over the country. However, as a local landmark building, how to measure the merits and demerits of large-span space structure design? What makes a great stadium? This requires our structural designers to select its structure. For the large-span roof, the structure selection is an important part of the whole design process, the purpose is: to ensure that the building function and shape meet the requirements of the premise, minimize the amount of steel, reduce the cost of the project, through the concept design to achieve the safety of the building structure, reasonable structure, complete function, economic beauty harmony, and unity.

One of the selection criteria for the China Steel Structure Gold Award” is “reasonable structure selection, clear force transmission route, simple and easy joint structure, convenient construction operation and quality assurance: reasonable design parameters, appropriate material selection, reasonable use of steel, Economical and applicable; advanced technology, with demonstration effect”. As an application of long-span space structures, stadiums have many factors influencing the selection of structures, mainly including the following points:

The sports stadium training building has one basement floor and four floors above ground, with a building height of 23.950 meters. Frame-seismic wall structure, the roof of the training building is a long-span space frame structure. The anti-seismic fortification category of buildings is Class B. The load-bearing structure of the large-span roof of the training building adopts a welded ball-node space frame structure. The space frame length is 72m, the width is 60m, the space frame is in the form of a quadrangle, the size is 6mX6m, and the height is 4m.

The pursuit of maximizing activity space has always been an important part of the history of human construction, which has resulted in many excellent long-span buildings. At the same time, due to the beautiful shape of the long-span space structure, the shaping of the interior space and appearance of the building has always been sought after by many architects. With the rapid development of my country’s national economy, the demand for sports venues is increasing day by day. The construction of sports venues is like a fire all over the country. However, as local landmark buildings, how to measure the pros and cons of long-span spatial structure design? How can we make excellent sports venues? This requires our structural designers to select its structure. For long-span roofs, structural selection is an important part of the entire design process. The purpose is to minimize the amount of steel used and reduce the construction cost on the premise of ensuring that its architectural functions and shapes meet the requirements. Through conceptual design, the harmony and unity of building structure safety, reasonable structure, complete functions, and economic beauty are realized.

Meeting the requirements of architectural functions is the root of the structural design of stadiums. As landmark buildings, different gymnasiums have different technological requirements due to their different functions and shapes. Therefore, when designing, the functional requirements required by various competitions and the like should be met.

Structural safety requirements. Since different stadium structures have different mechanical properties, they are suitable for different loads, structural shapes, structural spans, and boundary conditions. Therefore, the structural safety requirement is to maximize the consistency between the overall resistance and scope of application of the stadium structure, the characteristics of the specific scheme, and the requirements of the environmental conditions, while ensuring structural strength, stiffness, and stability.

Considering the feasibility of construction for any stadium, its technical performance and functions need to be realized by manufacturing and installation. Sports venues with different structural forms have a variety of installation and construction schemes. However, different construction plans have different requirements for the elements of construction feasibility analysis. These elements include the quality of fabrication and installation, the quality of the construction team, construction machinery, construction period, and construction cost.

Considering the economy requires that the selection of any stadium structure must be affected and restricted by the economy. It is dangerous to choose the structure of the stadium without considering the economic cost and blindly pursuing technological advancement or other performance requirements. The selection of different structural systems has corresponding requirements for the cost of construction of the structure of the stadium, daily maintenance costs, reinforcement, and the loss cost of the building’s expected disasters, and the comprehensive realization of these costs constitutes the economic performance of the stadium structure macro control. The above-influencing factors do not exist alone but are related to each other, restrict each other and depend on each other. The choice of any kind of stadium roof form is inseparable from the comprehensive evaluation of the above basic principles. In order to determine a better structural form, it is necessary to make a comparison of steel structure towers in terms of use, construction, structure, material selection, and construction. And proceed from reality, weigh the advantages and disadvantages, comprehensively analyze and consider comprehensively, and choose the optimal solution reasonably.

Space steel frame

The space steel frame, is mainly compared with the plane steel frame. The space steel frame is more complicated than the plane steel frame. The degree of freedom of each node increases from 3 to 6 or more. And there will be a balancing effect among the axial force between the members, bidirectional bending and torsion.

The space steel frame system mainly adopts the structural form composed of primary and secondary two-way radially connected steel curved beams and cross beams. The section form of the main steel beam mainly adopts the inverted trapezoidal box section, and the secondary steel beam mainly adopts the box section. The main steel beam is rigidly connected to the steel-concrete column supported by the roof, and the secondary steel beam is rigidly connected to the main steel beam. The cross-beam structure increases the number of statically indeterminate beams, makes the rigidity of the roof uniform, and allows the load to be transmitted to the surroundings in a dispersed manner. It often has good results when used in large-span roofs.

The total steel consumption of the steel roof is calculated to be 324 tons, and the steel consumption per square meter is 75kg/m2. The cross-sectional dimensions of the main components are shown in Table 1-1:

Table 1-1 Sectional dimension of main components

|

|

Steel main beam, steel main pipe |

steel secondary beam, steel secondary pipe |

steel bone column |

concrete beam connected to the top of the column |

|

steel roof |

Inverted trapezoid:2500x(700~400)x16x30x52; Inverted trapezoid:2000x(700~400)x16x25x44; Inverted trapezoid:1500x(500~300)x14x20x34; box shape:1500x400x14x25; variable section box:(2000~800)x400x14x20; variable section box:(1500~800)x300x14x20; box shape:800x400x14x20 |

box shape: 1500x400x14x25; box shape: 800x200x14x14; box shape: 600x300x12x12 |

1200×600 |

800×1500 |

Space frame structure

The plan projection form of the roof structure of the training building is a rectangle, and the upper chord is connected with the surrounding columns. Due to the use of square pyramids, the number of nodes and rods of the space frame is the least, the steel consumption is saved, and the roof drainage treatment and skylight setting are also more convenient. The spatial rigidity is larger than other quadrangular pyramid space frames and two-way orthogonal vertical space frames, the force is uniform, and the ductility is better, so it is advisable to use square pyramid space frame. The load-bearing structure of the large-span roof of the training building adopts a welded ball-node space frame structure. The space frame is 72m long and 60m wide. The space frame adopts the form of a square pyramid, the size is 6mX6m, and the height is 4m. The total steel consumption of the steel roof is calculated to be 280.2 tons, and the steel consumption per square meter is 65kg/m2. The method of assembling and installing the space frame has a significant impact on the selection of the space frame and even the cost and construction period of the entire project. The construction requirements should be taken into account when selecting the type of space frame structure so that the space frame structure can be safe, economical and reasonable.

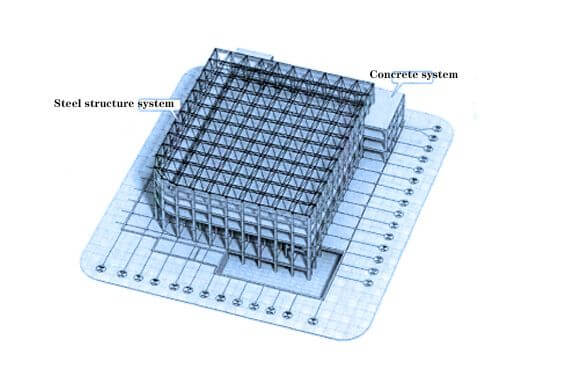

Figure 1-1 The overall 3D axonometric view of the roof space frame of the training building

Comparison of space steel frame and space frame structure

According to the influencing factors of structure selection, the comparison of space steel frame and space frame analysis is shown in Table 1

|

Structure type |

Building function |

Force performance |

Economic performance |

Construction feasibility |

|

Space steel frame |

Impact headroom |

Reasonable |

More steel consumption |

Easy construction |

|

Steel space frame |

Reasonable |

Reasonable |

Less steel consumption |

Complex construction |

From the comparison in the above table, it can be seen that although the space steel frame structure has relative advantages in terms of construction convenience, it has more advantages in terms of the simplicity of the internal space of the space frame, as well as the construction period and the adaptability of the construction plan. Therefore, considering factors such as architecture, materials, and construction, the final plan chooses the form of the space frame structure.

According to the structural characteristics and construction conditions of this project, the steel space frame roof adopts the construction plan of “assembly of platform parts-first hydraulic lift→second hydraulic lift”. Adopt the technology of “steel strand suspension load-bearing, computer synchronous control, and hydraulic jack group lifting” to carry out the overall continuous lifting of the network frame. The method is to set the hydraulic jack on the lifting bracket, the upper end of the suspended steel strand is fixed with the hydraulic jack, and the lower end is connected with the lifting object with an anchor, and the hydraulic jack clamps the steel strand to lift it up, just like lifting water in a well. The lifter mentions the installation height. The advantage of this scheme is that it uses the lifting bracket to bear the load, meets the characteristics of different elevations at each point, overcomes the difficulty of crane operation, facilitates the simultaneous implementation of assembly and quality control, and saves the construction period.