+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

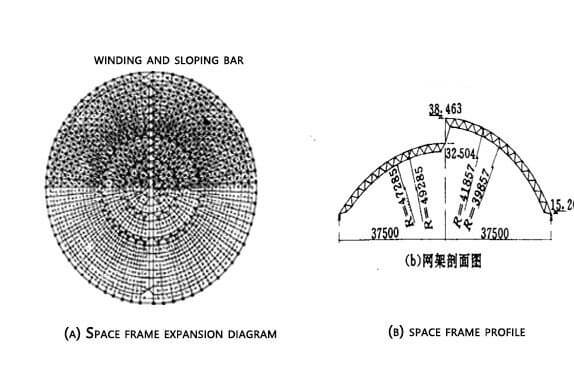

The water amusement park is an extra-large-span steel structure dome building. The dome adopts a spherical space frame with bolted ball joints scattered at the front and back, with a diameter of 75m, and is installed on a ring beam with an elevation of +15m. It is currently the largest double-layer special-shaped ball space frame with the largest span in China. It is not only difficult to design and manufacture, but also has great difficulties in installation technology. After the technical demonstration and careful organization of construction, it only took 42 days to complete the installation task with high quality and high speed and achieved good benefits.

1Project overview

The space frame of the Summer Palace is composed of two nearly quarter spheres with different radii scattered in the front and rear (as shown in Figure 1). The amount of steel used is 47kg. The vector height of the front shell of the space frame is 17.304m, and the vector height of the rear shell is 23.263m. The form of the space frame is basically a quadrangular pyramid, the space frame size decreases from bottom to top with the arc, the thickness of the space frame is 2.0m, there are 558 kinds of rods, 6365 rods, the largest steel pipe diameter is 4219X20; bolt balls 442 kinds, 1367 The maximum ball diameter is 250mm; the maximum high-strength bolts are M56; there are 69 supports, which are divided into four types: sliding supports, fixed supports, arch supports and front shell inclined supports. The load values of the space frame design are: static load (including the self-weight of the space frame) 2.7kN/m², wind load 0.4kN/m2, live load 0.7kN/m2; the seismic fortification intensity is 7 degrees, and the temperature difference change is ±32℃, the design stress is 190N/mm2. 190cm。 Structural calculation: the maximum axial tension of the rod is 372.85kN, the maximum axial pressure is 1471.76kN, the maximum plane displacement is 4.196cm, and the maximum vertical displacement is 8.190cm.

Figure 1 The dome space frame of the water amusement park

2 Selection of space frame installation scheme

The elevation of the highest point of the front shell of the space frame of the Summer Palace Hall is 32.50m, and the highest point of the rear shell is 38.46m, so the installation of the space frame has considerable technical difficulties and safety risks. Given the stress and structural characteristics of this space frame, we have comprehensively considered quality, safety, progress and economic effects, and combined with local construction technical conditions, we compared two space frame installation schemes:

Option 1: Component cantilever installation method In this method, an assembly scaffold with a width of about 8m is first erected on the inner ring of the reinforced concrete ring beam at the +15m elevation, and the space frame is assembled into a ring space frame with no less than three internodes by the bulk method. When the ring space frame can bear its own weight and has a structural system with overall rigidity, the long-arm large tower crane is used to hang the pre-assembled components on the ground to the circle to complete the installation of the entire structure.

Option 2: High-altitude bulk method This method uses fastener-type steel pipe scaffolding to build a complete operating platform within the scope of the 75m diameter leisure hall. Installation and structural characteristics, comprehensive consideration of quality, safety, progress and economic effects, combined with local construction technical conditions, we compared two space frame installation schemes: Scheme 1: Component cantilever installation method This method is first at +15m elevation The inner ring of the reinforced concrete ring beam is erected with an assembled scaffold of about 8m wide, and the space frame is assembled into a ring space frame with no less than three internodes by the method of bulk and assembly. When the ring space frame can bear its own weight and has a structural system with overall rigidity, the long-arm large tower crane is used to hang the pre-assembled components on the ground to the circle to complete the installation of the entire space frame. Option 2: High-altitude bulk method This method uses fastener-type steel pipe scaffolding to build a complete operating platform within the scope of the 75m diameter leisure hall. Install.

Comparison of the two schemes:

(1) For the cantilever method, three large tower cranes with an arm length of more than 50m must be set up. If this condition is met on site, only part of the steel pipe scaffolding needs to be erected, which saves time and costs. The bulk method must set up a large number of steel pipe scaffolding. Time consuming and expensive.

(2) The cantilever method has little influence on the civil construction inside the Leisure Hall. When the bulk method is used, the interior of the Leisure Hall cannot be constructed.

(3) When assembling by the cantilever method, the workers must stand on the installed space frame and work in the air, which is not as safe and reliable as the work directly on the scaffolding operation platform when the bulk method is assembled.

(4) When the cantilever method is used to assemble, the space frame is easy to generate large deflection and internal force during the installation process. Once a large assembly deviation occurs, it is difficult to correct. When assembled in bulk, temporary supports can be set between some nodes and the operating platform during the installation process, which is easier to avoid the possible drawbacks of the former, and the quality of the space frame assembly is easy to ensure.

(5) The bulk method has a sufficient assembly operation platform. If the personnel are reasonably organized, the installation period can also be appropriately shortened.

According to the above plan comparison and the actual situation on site, we finally decided to use the high-altitude bulk method to install the structure