+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1Project overview

The clearance requirement of a certain warehouse is 170m long, 80m wide and 75m high, closed on three sides, with a gate of 80mx65m on one side and a 5t electric hoist on the top. The building has the characteristics of a large span, high structure, super long, strict investment control, etc. In the design, it is necessary to analyze and compare the use of functions and construction conditions, as well as the aspects of structural force, functional modeling, economy, and constructability. On this basis, a structural plan is constructed to achieve the purpose of a safe and reliable structure, integration of structure and functional modeling, convenient construction, controllable quality, and good technology and economy. There are many large-span structures and towering structures at home and abroad, but there are few structures with both large-span and towering structures. Different from the general long-span structure, the large-span high-rise building has to bear a large horizontal load, which has high requirements on the lateral force resistance system of the structure. In addition, the building is equipped with an 80mx65m gate, and the stress and deformation of the door body on the structure are proposed. The high requirements have increased the difficulty of structural design.

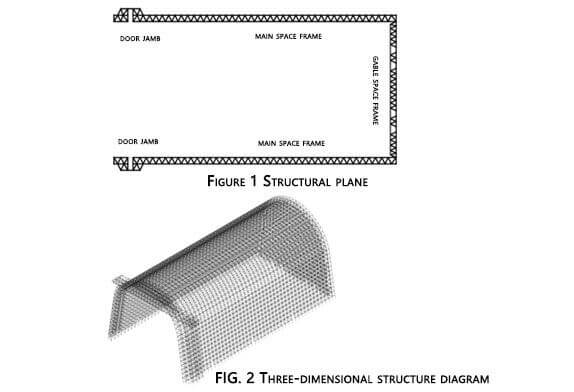

In the design, in order to give full play to the overall mechanical performance of the structure, the roof structure and the vertical support are integrated into consideration, the main shape fits the product requirements, and the mechanical performance of the arched design is fully utilized. Coordinate with the rigidity of the gable structure to reduce the torsional effect of the structure, and together with the main arch form a spatial space frame structure with good spatial performance. Figure 1 and Figure 2 show the structure plane and 3D model.

2 Main structure design

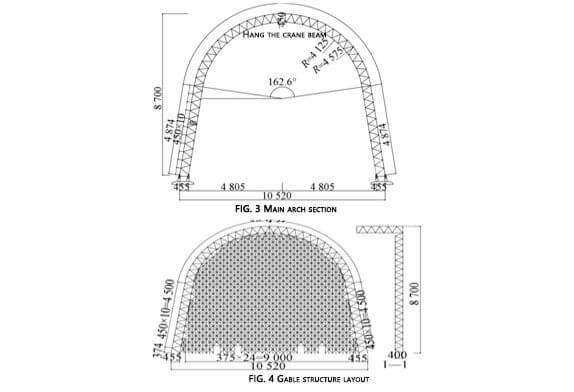

The main arch adopts an arched double-layered square pyramid reticulated space frame structure. Figure 3 shows the section of the main arch structure, the upper part adopts a cylindrical double-layered lattice shell structure, the cylindrical latticed shell is tangent to the inclined space frame column, and the column inclination angle is 7.5°. 5m, the height of the arrow is 4.5m. The axis of the outer chord column at the bottom of the building is 105.2m wide, and the outer chord arch is 87m high. Due to the curved surface shape of the arch, the internal force of the section is dominated by the axial force, the peak value of the bending moment is small, and the change is gentle. Under the action of horizontal wind load, the design value of the bending moment of the column foot is small, the arch frame is compressed as a whole, and the material utilization rate is high. The minimum diameter of the rod is 102mm. The upper arch space is used to lay out the hanging equipment, and after the column is tilted, the lower space can be used to arrange the measurement room outside the building in the building, which is beneficial to the development of the work.

3. Expansion and cumulative lifting construction

3. Expansion and cumulative lifting construction

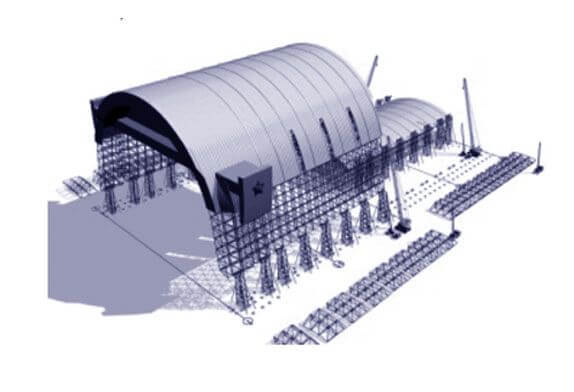

The structural height of the project is high and the span is large. According to the characteristics of this kind of engineering, the construction methods such as the integral lifting method, block assembling method, and integral tire frame slip method are often adopted. After careful consideration of construction difficulty, safety, quality, cost, and other factors, the project adopts the construction scheme of expansion and cumulative lifting, using the overall hydraulic synchronization, and lifting technology for installation. Expansion lifting construction in the plane will be divided into two zones for construction successively :(1 ~@) axis and (25~48) axis, the middle of the two zones 3m distance is the steel structure after the filling rod, as the construction closing joint; (①-@) axis area is provided with 8 groups of lifting equipment on both sides of the structure; In the (25-48) axis area, 8 groups of lifting equipment are arranged on both sides of the structure; In the process of outward expansion, a total of 6 lifting support replacement operations were carried out, and the high arch structure was vertically divided into 7 parts for lifting. Each lifting unit was further lifted three times, each lifting about 6m. FIG. 5 shows the construction axis side diagram.

FIG. 5 Side diagram of construction shaft

The first unit on assembling platform assembly is completed, and then the use hydraulic jack will increase 1 unit to a certain height, then improve 2 unit assembling, raise 2 after the completion of the unit is assembled, space frame setting in supporting the whole horse stool, then improve the stand down to the second unit lifting point, improve unit 1, 2, to a certain height, Then proceed to lift the construction of 3 units. According to the above construction method, units 1-6 are successively lifted, and installation unit 7 is directly installed in place by means of block lifting. It has obvious advantages to adopt the expansion cumulative lifting construction scheme and adopt the integral hydraulic synchronous lifting technology for installation. First of all, the grid structure of the main assembly, welding, and painting work near the ground can be used for small car crane parts assembly, multiple operation surface parallel construction, high construction efficiency, construction quality is easy to ensure, is conducive to the overall project period control. Secondly, the auxiliary sub-structural parts on the structure of the network frame (roof label, horse way, and part of the roof board) and so on are installed with the network frame, on the installation, which can reduce the workload of aerial lifting to the greatest extent, shorten the installation construction cycle. Third, the use of hydraulic synchronizing lifting construction technology “very large components hoisting large span steel structure, mature technology, improve the construction process of safety guaranteed, through the factory network frame integral hoisting, high altitude work will come to a minimum, combined with the hydraulic lifting operation absolute time is shorter, can effectively guarantee the overall construction of the steel structure installation.