+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

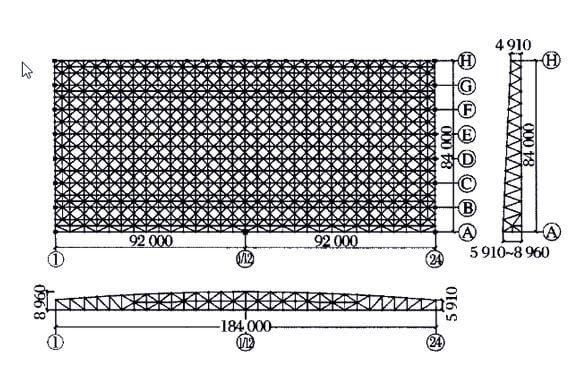

Hangar no.11 of Guangzhou Southern Airlines is composed of a steel space frame of hangar roof, supporting column, and support system between columns. The plane size of the roof steel space frame structure is 184 m×84 m, and the center elevation of the lower chord ball of the space frame is 20m. It is a double-layer diagonal four-angle steel space frame with a space frame size of 6m×6 m and a height of 5.91 ~ 8.96 m. The overall structure is supported by 28 concrete columns.

The structural plane layout of the hangar hall in this project is shown in Figure 1. The supporting column is made of a reinforced concrete column, ○H axis supporting column distance from 8,12,16, 24 m, ① axis, and ○24 axes supporting column distance from 12m. The support between columns adopts double-leg lattice steel support.

Figure 1 Overall plane and side diagram of the hangar

The core-piercing hydraulic hoist is used to lift the assembled space frame to the design elevation, and local rods are repaired after lifting in place. Finally, to remove the temporary support of the space structure, the specific construction steps are as follows:

1) Ground assembly. The center of the lower chord is 1 m from the ground. The space frame is symmetrically assembled from the middle to the east and west sides.

2) Installation of lifting support and equipment. After the construction of the civil concrete column reaches the specified strength, install the lifting bracket and lifting equipment.

3). After the completion of space frame structure assembly, all hoisting equipment has been installed in place. After checking all the system is normal, lifting will be carried out. The overall lifting will be completed in three steps. A. Trial lift: after the first lift of 200 mm, stop for 12 h, check and monitor the deformation of the lifting system, equipment and space frame. B. Formal lifting: the lifting speed is controlled at about 4 m/h, the lifting height is about 19 m, and the lifting process shall be monitored in real-time. C. Lifting in place: after lifting the space frame to the design position, stop, and fine-tune each lifting point to accurately lift the space frame to the design elevation.

4) Local rod repair. After lifting in place, the rod is installed after repair. The top joint and support of the column are repaired first, then the top joint and rod around the support are repaired, and the remaining rod is repaired finally.

5) Remove temporary support. After all the welding is completed and inspected qualified, the temporary support of the whole space frame shall be removed by classification.

6) Remove temporary structures. To complete the removal of the space frame support, remove the structure outside the structure (lift, lifting platform, temporary rod, etc.).