+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

With the continuous development of construction projects, the application of steel structures in the construction field is widely used. In the process of highway toll booth canopy construction, the use of steel structures gradually become a relatively mainstream trend in China. With the continuous development of social needs and the continuous renewal of construction engineering technology, various personalized steel structure charges have emerged, prompting highways to be more distinctive and more beautiful. A steel structure highway toll canopy is a type of structure used at toll booths and other roadside locations. It is designed to provide shelter from the elements for workers and customers. It typically consists of a steel structure with a color steel plate roof, sides, and back to protect from the sun, rain, or snow. The canopy may also feature awnings on the sides and back to provide additional shade. These canopies can be custom–designed to meet the specific requirements of a particular location.

Figure.1 highway toll canopy

The preliminary planning of a highway toll canopy is planned at the national highway section, located at the intersection of a highway at a certain city-level city. Combined with the construction plan, the appearance of the charging canopy presents a wave-arched style, and the tie rod is set on each side to make the appearance style more symmetrical and balanced.

The structural span of the highway booth canopy is 42m, the other direction span is 14m, and the net height of the building is 15.5m. The main construction difficulties faced by the project in the actual construction process are the large span of the building. In order to ensure the safety and reliability of the structure, it is necessary to go to the construction site for the survey. In order to reflect the modeling effect of the building, the project department combines the scene on the scene. The actual situation proposes two different design solutions. The first plan is designed with a quadrilateral truss structure; the second solution is designed with a box arch structure. These two design schemes are tentatively used to use Q355B steel.

In the process of toll canopy steel structure construction, the main steel is low alloy high -strength steel, and the proportion of alloy elements should be less than 5%. At the same time, the yield strength is less than 275MPa. Welding construction can be performed, and the molding performance is good. Low -alloy high -strength steel has not been heating treated and cutting and has an important proportion in my country’s entire steel structure project. The quality control content when making components includes the fetal frame, assembly operation positioning, and the benchmark line construction. The technicians must also strictly control the control according to the operation specifications. In the process of making components, overall stability must be guaranteed. The calculation formula of the main parameter λ is as follows:

λ is the length of the component, m; r is the radius of the section,

λ is the length of the component, m; r is the radius of the section,

In order to ensure the scientific and accuracy of the research, the research model is built with the help of the MIDAS GEN software, using the beam unit for simulation, and restricting parameters such as short value tests, so that the unit can only bear the tensile force and pressure, and all nodes are based on the characteristics of the force. Set to compare.

In terms of the relevant content in the (GB 50009-2012) (GB 50009-2012), the structure of the building is as follows.

(1) Dead load: excluding the weight of the main structure of the building itself, the upper and lower chords of the weight calculation standard value of decorative decoration materials are 0.40kN/m², and other loads shall not be suspended on the steel members to prevent structural damage caused by the force exceeding its design value.

(2) Live load: 0.50kn/m².

(3) Basic wind pressure: 0.60kn/m², the reappearance period is 100 years, and the ground rough sugar is B.

(4) Basic supervisory pressure: 0.35kn/m², the reappearance period is 100 years,

(5) Earthquake load: Design the earthquake intensity 6 degrees into the first group, class Ⅱ venue.

(6) Construction load: 1.0kn.

(7) Landmark text load.

According to the load requirements and the requirements of the building, the facade establishes the relevant model, in the case of meeting the requirements of strength, stiffness, stability, preliminary square, and case comparison. In the case that the deflection of standard load wear meets the requirements, the deflection of scheme one is slightly larger than that of scheme two, the maximum stress of the beam element in scheme one is slightly larger than that of scheme two, and the maximum horizontal reaction force of the support and the amount of steel used in scheme one is significantly smaller than that of scheme two. Further, although the deflection of the scheme one is slightly larger than that of scheme two, the performance of other aspects is more ideal than that of scheme two. After the multi-faceted tradeoff, the first scheme is determined as the final structure scheme.

The specific process of steel structure optimization is as follows: reasonable hypothesis→analysis of the actual situation →scheme comparison → determine the optimal scheme, scheme comparison is the most important link in the optimization process, it needs to judge whether the various schemes can effectively meet the actual construction needs, if it fails to meet the construction needs, part of the rules should be revised. In order to achieve the goal of the optimal design scheme. The optimal design of a steel structure can be roughly defined as determining the known parameters and obtaining the design values that satisfy all the constraints.

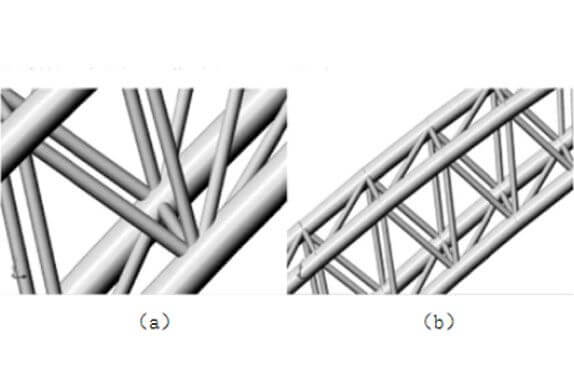

Combined with the above results, the quadrilateral truss structure was finally determined. The connection method of the first designed truss arching surface rod is shown in Figure 1 (a), that is, connecting through three web chords. This connection method will cause many construction difficulties in later construction. Therefore, in order to provide convenience for construction, and strengthen construction efficiency and construction quality, the three web chord need to be changed to 2web chords. The specific form is shown in Figure 1 (b) Figure 1. Optimization of the structure form of the web chord

Figure 1. Optimization of the structure form of the web chord

In the process of optimizing the steel structure, a physical research model should be constructed, which can intuitively reflect the spatial relationship of each component of the steel structure, can effectively avoid the emergence of cross-phenomena. Steel structure as far as possible does not use large diameter steel pipe or pipe walls too thin steel pipe. When optimizing the steel structure, the bearing capacity of the connection point should also be calculated. For parts that do not meet the design needs, measures can be considered to take measures such as thickened tube walls.

The overall optimization idea is to reduce the weight of the overall structure or reduce the price reasonably. First of all, you can calculate it from the perspective of the load. After accounting, the upper and lower string can be reduced from the original 0.40kn/m2 to 0.35kn/m2, and the constant load is reduced by 12.5%. In order to reduce the structure and ensure the unity and coordination of the facade outside the building, the steel column section can be set to the steel truss column. In addition, for the trussed rod and part of the string rod with a small stress ratio, you can also use the method of replacing steel to reduce the overall cost, such as changing Q355B steel to Q235B steel.

The section not only needs to ensure the strength of the structure itself, but also to ensure the stiffness of the structure, and should be estimated to the convenience and economy of the actual construction. This is because the construction industry is developing rapidly, and some practitioners may not know much about new technologies or new materials. In this case, although the designed products may effectively meet the needs of structural stability, the designer has not considered the scene at the scene. The difficulty of actual construction has prompted the installation of the final design to be very difficult. On the one hand, unreasonable sections may lead to increased construction costs; on the other hand, when the construction process cannot effectively meet the design requirements, the security of the structure may not be effectively guaranteed.

When optimizing the cross-section design, the Midas Gen software can be appropriately used. This can ensure that the deflection of the section meets the design specifications, further reduce the section stress ratio, and keep the cross-section stress ratio of 0.80 to 0.85. After optimization, the consumption of steel can be effectively reduced by 15%.

For nodes with a large number of rods and a small angle, or in a scene where the node structure is relatively complicated, welding can be used for steel plates or profiles. However, this welding method is difficult to operate and cannot be guaranteed in quality, so cast steel joints can be selected. The steel-casting nodes are all formed at one time, the appearance quality is relatively high, and they can withstand greater external forces, but their costs are relatively high. If a node of a steel bars hook is relatively large, the use of axis nodes may produce a large force, which may promote the steel structure to face a certain potential risk. At this time, it is more appropriate to choose the joint bearing node. At this stage, the frequency of joint bearing in the construction of steel structures in domestic construction engineering is relatively high. In actual purchases, you should pay attention to the life cycle of the node.

During the construction of a greenhouse steel structure, it can be connected by welding in the slopes. The main beams and steel columns are welded when connected, and the upper and lower wing margins are used to connect to the upper and lower wings. When welding the beam pillar, the order, bottom, and middle order. The two components are connected according to the main components and secondary components. The work components are constructed in the order of the upper wings, wing margins, and abdomen. The anti-corrosion treatment of steel components is the most important, and it will have a greater impact on the safety and durability of charging greenhouses. In the construction of the steel structure of the charging greenhouse, you must choose the appropriate anti-corrosion measures. The common way is to apply the protective layer. This method can ensure that the steel electrochemical anti-corrosive performance is excellent and can be coated with metal.

Optimizing the steel structure can not only reduce construction costs but also better ensure the stability and intensity of the steel structure. The optimization of the steel structure must be fully considered the purpose of the structure, the weather environment, the technical level, the construction conditions, and the stress performance. Steel structure operators must master comprehensive theoretical knowledge so that they can design better products. After a comprehensive contrast analysis, it is found that the performance of the arched structure of the truss is significantly better than the box-type structure. The project uses Midas Gen software to analyze, and the analysis results show that all structural indicators meet the design requirements.