+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

1Project overview

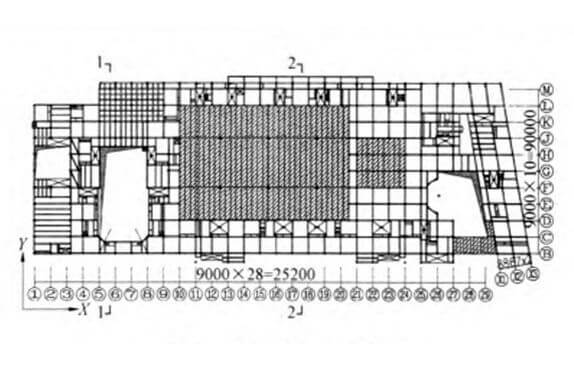

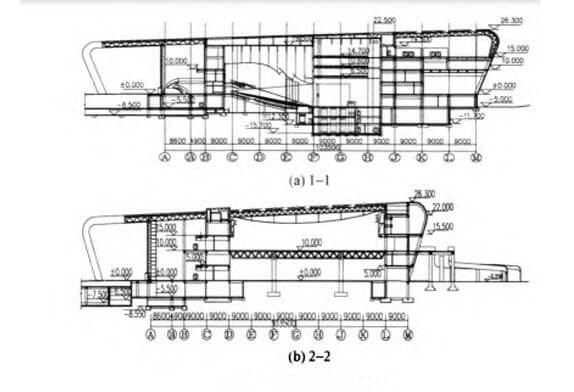

The single main buildings of the Cultural and Sports Center include the Convention and Exhibition Center and the Stadium. Among them, the exhibition center has a construction area of about 98238m2, 1 underground floor, and 4 above-ground floors, with a total height of about 25.4m and a plane size of 119.6mX302.5m. There is no permanent joint as a whole, and the cast-in-place reinforced concrete frame-shear wall structure is adopted. The part of the exhibition hall on the 3rd floor spans 27m and adopts a steel-concrete column and steel truss system. The roof of the exhibition center adopts the steel structure of space steel pipe truss and steel pipe string truss, the maximum span of the roof truss is 64m, and the maximum length of the roof truss cantilever is 25m. The typical plan of the convention and exhibition center is shown in Figure 2, and the cross-section is shown in Figure 3.

FIG. 1 The real scene of the Cultural and Sports Center

FIG. 2 Typical plane of the exhibition center

FIG. 3 Section of exhibition Center

2 The main design difficulties of the project:

(1) The plane size of the structure is too long, and permanent joints cannot be set up, so the seismic resistance and crack control of the structure are the difficulties and the key points of the project.

(2) Engineering buildings have complex functions and large differences in building space. Different structural forms need to be selected to achieve building space requirements. Therefore, it is often necessary to combine multiple analysis programs for analysis. Different structural forms often need to adopt different connection methods to ensure structural safety. .

(3) In order to reduce the size of the large-span space and the large-span cantilevered members, a number of technologies such as prestressed steel structure and prestressed concrete structure are used in the design to make the structure light and not clumsy.

3 main structure design

3.1 Main material and component size

The lower part of the exhibition center is mainly a concrete structure. The strength grade of concrete for shear walls and frame columns is C40, and the strength grade of beam and slab concrete is C30.

The exhibition center mainly adopts a steel structure roof, the steel strength grades are Q345B and Q345C, the steel cables are plastic sheathed semi-parallel steel wire cables, the main cable section is 151∅5, and the breaking stress is 1770MPa.

3.2 Analysis of the overall structure

The convention and exhibition center integrates various functions such as exhibition, theater, technology center, dome theater, and banquet hall. 64m and other spans, with two major earthquake-resistant adverse factors, large-area openings, and plane torsion irregularities, belong to Class B buildings. In order to effectively improve the overall seismic performance of the structure, the overall use of cast-in-place reinforced concrete frame after comparison of plans. In the shear wall structure system, a total of 24 shear wall tubes of different sizes were set up, and special attention was paid to the setting of shear wall tubes around the large opening floor slabs, which effectively alleviated the adverse effects caused by the differences in seismic performance of various functional areas.

3.3 Steel structure design of the front hall

The plane size of the steel structure of the front hall is 49m×300m, and the maximum cantilever length is 25m. The bidirectional anti-side system composed of triangular space steel pipe trusses can effectively resist vertical and horizontal loads.

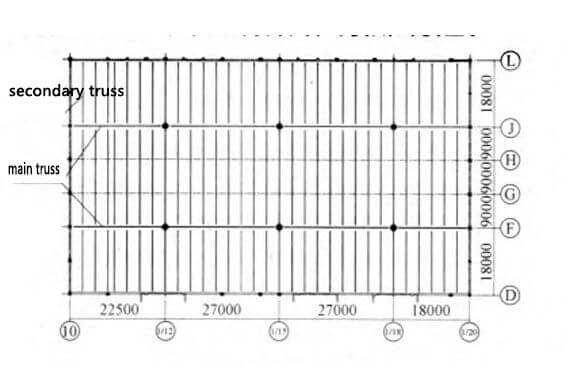

3.4 Design of the steel structure of the exhibition hall floor

The floor plan size of the exhibition hall is 63m×94.5m. According to the exhibition requirements, the floor live load reaches 15kN/m2, and the span is divided into three types: 18, 22.5, and 27m. The combination of an H-shaped steel truss + closed profiled steel plate is used. The floor system and frame columns are made of steel-concrete columns. The secondary truss adopts the upper bearing type H-beam steel truss, which can prevent the concrete beam connected to the truss from generating large torque, and at the same time can ensure that the lower chord is in a tension state.

FIG. 4 Main and secondary truss layout in the exhibition hall