+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

I. Overview of the stadium

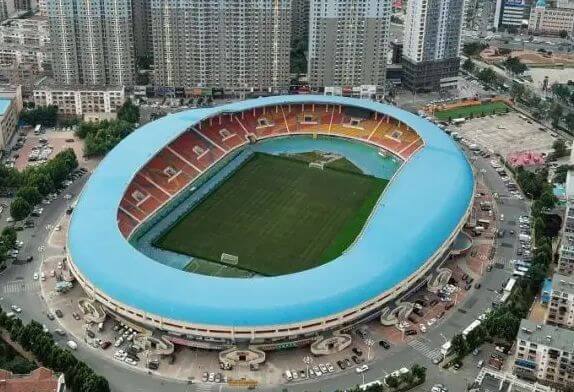

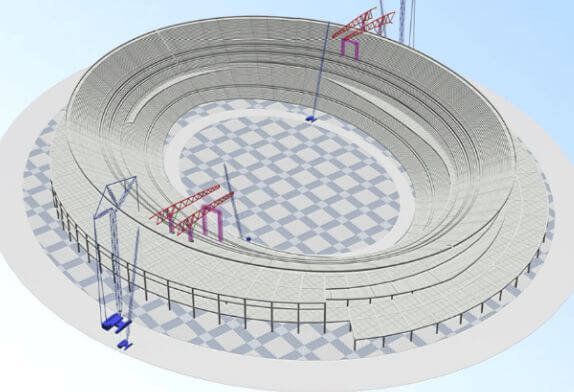

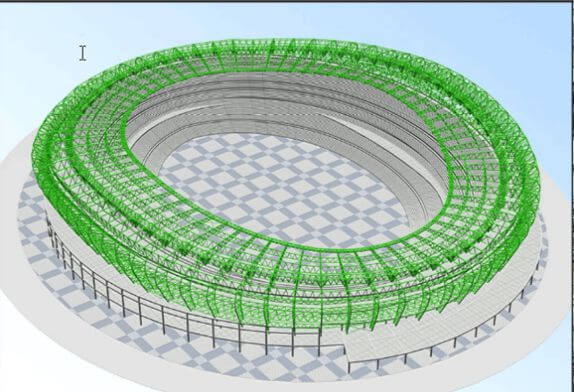

Dalian Stadium, 319.792 meters long, 293.145 meters wide, steel structure bottom elevation 7.100 meters (hinge support); The high point net height is 45.442 m, and the low point net height is 30.950 m. It is mainly composed of 68 main trusses and 6 tie ring trusses. The roof is purlin with rectangular steel tubes. Each of the main trusses is rigidly connected with the ¢700*30 hemispheric support at the bottom (the top of the grandstand) and hinged with the support at the rear. The heaviest single truss is 65.4t (HJ-1) and the lightest is 48t (HJ-18, HJ-19). The ring truss has 6 rings. Nearly 9000 tons of steel structural members. As the length of the pipe truss is about 60 meters, the main truss is mostly divided into 4 sections and the ring truss is fragmented and part of the rods are delivered in bulk. Due to the installation needs, the main truss spliced two welds on the ground and assembled a weld in the air. Part of the ring truss is assembled on the ground, and the four ends are assembled in the air with the main truss. The steel structure should be coated with two primers in the factory and the remaining intermediate and topcoat on site.

II.the basic idea of installation

The main truss shall be installed from the horizontal strut element to both sides to reduce accumulated errors during installation. The main truss fixed end for a total of two points, but because of its small on the big, after the completion of application to install cable wind rope fixed, until the installation in nature, fixed end after the installation of ring truss, forming a stable unit is on to the next unit of construction, in the main truss structure of fixed end another installation process for the first unit installed cable wind rope shall not be removed, Radial and tangential measurement control points or lines are marked at the fixed end for inspection at any time. For mass welding, at least two units should be installed behind time, and the overall truss offset after welding should be monitored for time adjustment. The ring truss is divided into six bands, which are just connected with the main truss as a whole stable structure. The steel tie rod mechanism is a mechanically connected flexible mechanism, which also ensures the stability of the whole truss. Purlin systems are made of rectangular steel tubes rigidly joined together as a whole with steel connections to the main truss (or ring truss support) joints.