+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

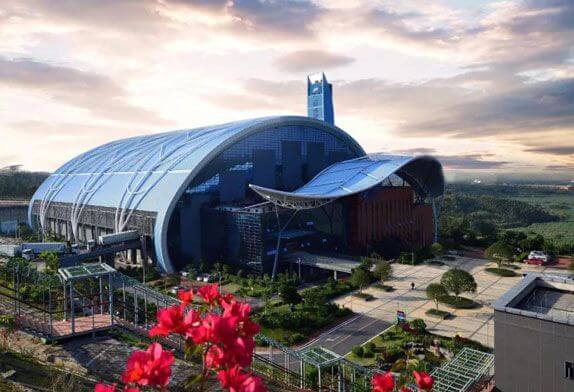

Figure 1 Industrial workshop space frame roof

The industrial workshop roof construction project has a space frame of 140.5 meters in length and a span of 122 meters, using around the support of the chord column point support, is a square pyramid structure, bolt ball and welding ball mixed node space frame. The elevation of the top of the column is 9.6m, and the vector height of the space frame is 4.80m. Structural form: positive quadrangular pyramid space frame; node type: mixed with bolt balls and welding balls. The total area is 16,950 square meters. The installation of the space frame is divided into three areas. The maximum weight of the space frame in the area is about 378 tons.

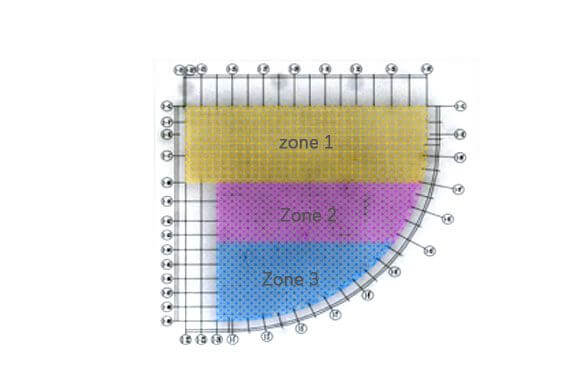

Figure 2 schematic diagram of partition

Due to the large installation area, large span, complex structure, and the large area of the enclosure structure of the space frame of this project; a large amount of material procurement; a large number of components, large production volume, high precision requirements; large amount of welding; hoisting difficulty, in order to ensure the quality and safety of an installation, after technical and economic comparison, the ground is assembled in blocks, and the construction is carried out by the overall lifting method of multiple groups of pulling rods. The engineering construction technology is complex and the quality requirements are high

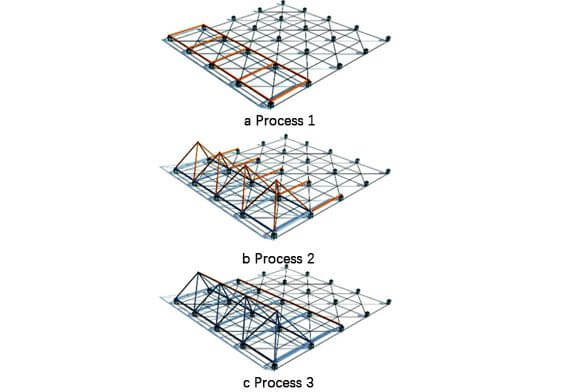

The lifting of the space frame is carried out in stages. The lifting of the space frame is an important stage of the installation of the overall space frame, and the lifting height should meet the requirement that the space frame falls on the embedded parts of the reinforced concrete support column. After lifting into place, first, assemble the rods and bearing balls at the support position of the space frame in high altitude and bulk, and then place the space frame as a whole on the fulcrum of the column.

3.2.1 In the first stage, the floor of the space frame in Zone 1 is assembled, and the lifting rod is set symmetrically. A zone space frame is assembled in the site, and 10 groups of 18-meter-high lattice rods are evenly arranged within the range of the zone space frame.

3.2.2 In the second stage, the space frame in the first area is raised to an elevation of 10.2 meters.

3.2.3 In the third stage, the space frame of the second area is assembled on the ground, and the lifting and pulling rods are evenly set at the same time. The space frame in the second area is assembled on the ground, and the connecting rods in the adjacent parts of the second area are temporarily vacated. After the space frame in the third area is raised to the design elevation, the second area is lifted for aerial closure.

3.2.4 In the fourth stage, the steel roof structure space frame in the third area is raised to an elevation of 10.2 meters to connect with the space frame in the second area. Use a spirit level to level the elevation of each docking point, and adjust the axis and level before carrying out high-altitude bulk docking. The bulk docking is carried out with a construction crane, and the bulk docking is carried out from the middle to the two sides. After the docking is completed, retest. After adjusting the axis and level, the space frame is seated; after the seat is placed, check it, and after meeting the various technical requirements of the space frame design drawings, the support is in place and fixed.

Construction preparation→review of support fulcrum→ground assembly space frame→block lifting→high-altitude closing→calibration→support welding→repainting and fire-resistant paint→acceptance.

4.1.1 Ground assembly and wiring. Use the total station to release the orthographic projection line of the “space” on the ground as a control line for the ground assembly of the “space”.

4.1.2 The erection of the assembled tire frame. The assembled tire frame adopts concrete short columns to ensure that the strength, rigidity, and stability of the short columns meet the requirements, and the height is generally 500mm.

4.1.3 Steel structure workshop construction process of space frame ground assembly:

4.2.1 The setting position of the lifting rod should be close to the force condition of the steel structure space frame when it is in use. At the same time, the position of the button pole should be symmetrical and evenly distributed, and the wire should be laid out accurately.

4.2.2 In order to ensure the verticality of the button pole, theodolite should be used in the installation process of the button pole. The single button pole should be adjusted and fixed at any time with the cable wind rope during the installation process.

4.2.3 The bolts and diagonal braces of the button pole should be installed in time and evenly tightened during the assembly process.

4.2.4 After the overall installation of the pull rod is completed, it should be checked as a whole with the theodolite.

4.2.5 In order to prevent the center point from shifting after the button pole bears the load, the end of the button pole must be tightened with cable wind ropes in series, and pay attention to the uniform force of the cable wind rope when tightening, and fasten it with a buckle.

4.2.6 The end of the cable wind rope of the button pole should be fastened with the ground anchor or building, and the burying of the ground anchor should refer to the relevant technical specifications.

When the steel structure roof space frame is assembled on the ground, the corresponding number of lattice-type well-shaped frame pull rods are arranged according to the positions specified in the lifting point diagram. After the installation of the button pole is completed, after the space frame is assembled and accepted, it will be lifted. Each set of pull rods is set up with 10T×4 reverse chains for lifting. the chain back shall have no broken marks and be smooth, and the product shall be qualified. When lifting, hang 8 steel tape measures at the appropriate position of the space frame, check the lifting speed of each point in time, and ensure the synchronization of the lifting of the space frame. In order to ensure the safety of the civil structure after the pulling rod is lifted and bearing the load, an 800mm×800mm×20mm thick steel plate is placed at the position where the pulling rod is set. In addition, the ends of all pulling rods are fastened in series with Ф14 steel wire ropes to ensure the integrity of the pulling rods. The four corners of the end of the button pole shall be provided with cable wind ropes. At the height of 10 meters of the pulling rod, four (two main and two attached) cable wind ropes shall be set and fixed on the building structure or on the pre-set ground anchors. When fixing on the building, the fixed points should be wrapped with angle steel or square wood and reinforced. When lifting, the horizontal position of the grid frame should also be set with 8-10 5-10T inverted chains to control the slight swing of the grid frame during lifting. resulting errors.

After the steel structure space frame is lifted and assembled in stages to the column point position, the axis size of the entire grid should be corrected. First, correct the axis size of the lifting rod, and then use the rod to correct the axis of the grid after the correction. Re-measure the axis and elevation of the top of the concrete column in advance, and if any problems are found, they will be dealt with according to the design requirements of the specifications until they meet the requirements of specifications. Place the transition plate of the support and the hollow ball on the top of the column, and install the space frame rods connected to the hollow ball according to the figure, so that the space frame is initially stabilized on the surrounding column. After the docking of the space frame and the installation of the rods are completed, the axis of the entire grid frame should be adjusted, the space frame should be raised again by 30mm, and then slowly dropped. During this process, the displacement value and elevation value of each support should be checked in detail. Securely install the support transition plate. The installation of the space frame should pay attention to the force of the support, and the construction of the support of the space frame should be carried out in strict accordance with the design requirements and product instructions. The support pads, limit plates, etc. should be installed in the specified order and method.

The method of block lifting has the following advantages in this industrial workshop project:

(1) It is not necessary to support and reinforce the concrete floor that has been poured in a full range, and only support and reinforce the part where the lifting handle is set, which reduces the need for reinforcement. difficulty and scope.

(2)Since the assembly of the space frame is carried out on the ground, it is convenient for the quality inspection department and the supervision company to supervise and inspect the installation quality, and the problem of vertical transportation is also solved. This can undoubtedly greatly improve the quality of installation and shorten the construction period of the installation project in the construction site where there is no large hoisting equipment available.

()After the spaceframe is installed on the ground, after self-inspection and inspection, it can wait for the paint to be repainted and the fire-resistant paint to be painted before upgrading. It greatly reduces the construction difficulty of the subsequent process, can improve the construction quality, and at the same time provides a working surface for the subsequent roof panel installation as soon as possible, thereby greatly shortening the construction period.

(4) The preparation time of lifting and drawing rod set is short, the removal is convenient and the cycle is short. To sum up, this paper analyzes and expounds the relevant contents of steel grid installation and technical points of industrial plants from different aspects and angles, so as to achieve the maximum comprehensive benefits, and to the development of industrial industry, but also to give certain support.