+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

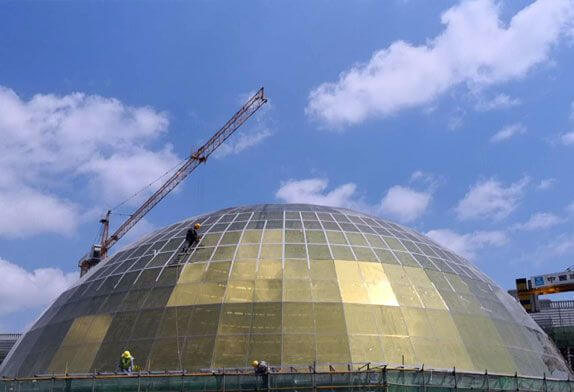

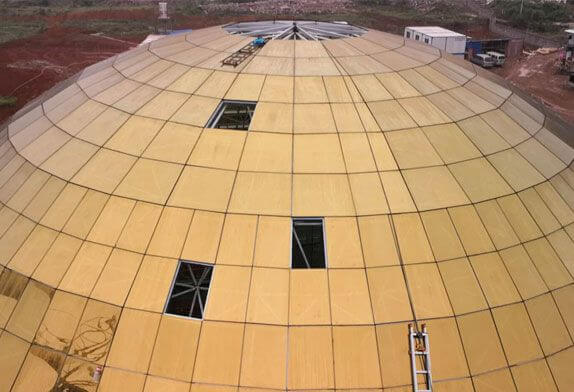

In the process of steel construction of long-span domes, the construction of steel structures is mainly carried out in areas with large span spaces. Designers should scientifically carry out relevant design work according to structural characteristics, improve the construction mode and mechanism, and improve the design. Simultaneously with the construction, the engineering construction level is improved, highlighting the structural advantages and functions of large-span dome steel, and achieving the expected design and construction goals.

In the construction process of large-span domes in the field of modern architecture, the previous single structural form has been transformed, and a diversified combined structural mode has been formed. During the rapid progress of steel structure technology in my country in recent years, the previously adopted single structure form has begun to transform into a diversified structure form, in which many new technologies have been used. Stress technology creates a dome steel building structure with a high span, which provides certain support and guarantees the effective construction of the overall project.

Generally speaking, for long-span domes, the scale during the construction period is relatively high, and the structure is composed of many components, the largest number of which can reach hundreds of thousands. There are certain differences in the size and length of the components, which will lead to The construction of the project facing many difficulties. During the construction of complex structures, especially some twisted dome steel structures, professional design work and test work are required to enhance the construction effectiveness of the project. Provide certain support for the good construction of the dome steel structure.

At present, many national-level key engineering fields in my country have begun to apply long-span dome construction technology, especially in the construction field of some stadium projects. Due to the high requirements for construction quality, in order to better meet the high standards, Strict requirements, it is necessary to ensure the accuracy of construction work, improve the accuracy of the structure to the highest extent, and control the construction of welding seams to the first-level standard, which will increase the difficulty of construction and must be strictly controlled.

In the process of actual design, the stability calculation of the dome steel structure roof should be carried out scientifically. According to the technical regulations of the space frame, the stability calculation activities of grid lighting should be carried out accurately. In the initial stage, the geometric nonlinear analysis method should be used to study the defect situation. Data values for the initial imperfection are extracted in the first mode of buckling. In the process of carrying out the stability calculation work, it is necessary to focus on setting the permanent and variable loads in the node area equivalently, use the means of displacement control to analyze reasonably, combine the information and content of the nonlinear working condition to clarify the highest displacement node, and regard it as It is the main control node in order to effectively perform stability calculation work. Designers also need to focus on the work related to structural calculations, and calculate permanent load data values, hanging load data values, wind load data values, earthquake action data values, and temperature data values to ensure the accuracy of calculations. In the design work, finite element software should be used reasonably to carry out calculation work, improve the calculation model, obtain accurate results, and facilitate relevant design activities. ,

Designers should focus on the platform design of temporary support and high-altitude operations in their work to ensure the stability and rationality of the overall platform. During the design process, the column section data value, horizontal tooling data value, diagonal bracing data value, tooling tie rod data value, maximum height data value, etc. should be clarified. At the same time, the angle steel processing design and installation design of the web bar should be clarified. Reasonably design the truss scaffolding platform around the tooling, and specify the specifications of the truss section, material section, and web material, so that an accurate basis can be provided for the construction of the project under the condition of reasonable design.

First, during the specific cumulative sliding process of the dome steel structure slip unit, the slipping structure needs to have a guiding function and Heaviness acts to achieve the restrictive purpose of making displacement. The outer ring part should be designed as a reinforced concrete column structure, and the concrete column is combined with a truss-type sliding beam to make it a full-length slideway. The inner ring part needs to be designed with a temporary support part, and a ring is designed in the top area. trail of. Secondly, in the design of the track elevation, attention should be paid to quickly opening more obstacles, considering the sliding girder as a temporary part, and directly setting the slideway on the surface area of the girder. Finally, attention should be paid to the coincidence between the centerline of the track and the axis of the girder during the design period to prevent the problems of horizontal propulsion and excessive self-weight load during the sliding process, reduce relevant data values, and ensure the effectiveness of the design. It should be noted that the track should be designed using hot-rolled steel channels welded to the girder surface area. In the domain, the baffling part is designed on both sides so that it can form resistance to the lateral thrust during the sliding process of the support.

During the steel dome design of the bearing, you can choose to use the permanent structure as a sliding bearing, in which a temporary bearing part is designed, connected to the upper part of the gable column, and a high-quality connection with the ring truss. Designers need to pay attention that the part around the support needs to be parallel to the tangent line of the centerline of the slideway and have interconnected pores with the inner wall area of the steel channel, which play a certain sliding guiding and restrictive role.

In the specific construction work, attention should be paid to the reasonable installation of the outer way. Due to the high length, the measures of segmented installation can be adopted in the project area. In order to improve the level of the slideway, reduce the friction coefficient, and prevent the problem of obstruction, the installation During the process, a large number of surfaces and the lower surface of the slideway should be reasonably padded with the help of thin steel plates. For the welded part of the steel channel segment, single-sided welding technology can be used to grind the welded part with a grinding wheel to carry out slippage. Grease lubricating treatments are also utilized during the testing campaign. In the specific installation work, the track should be installed in the lower part of the ring truss. There are two types of inner track and outer track. Installation activities are carried out with the support of After that, measurement and setting-out should be carried out, and setting-out should be carried out at the construction site according to the project conditions to obtain accurate measurement data values and provide corresponding data content and information for subsequent construction.

For the dome steel components, attention should be paid to the sliding installation of the dome truss steel structure during the specific construction period, and they should be closed to enhance the construction effectiveness of the dome steel part. First of all, in the process of component construction, the simulation analysis of component slippage should be focused on. In the simulation work, the three-dimensional real scale of the space is selected as the calculation model, and the degree of freedom of the grid steel structure is set. According to the situation, one degree of freedom can be set. , two nodes. In the specific construction simulation work, it is necessary to study the bending internal force, shear internal force, compressive internal force, and twisting internal force of the structure to obtain the data value of the structural deformation characteristics. After completing the simulation analysis, it is necessary to carry out temporary support in it For some construction activities, the observation control points are set at the position with the highest force deformation data value, so as to reasonably complete the monitoring work of slippage construction, and the construction personnel is required to use the detection data information as a basis to strictly prevent the dome steel during construction. The stress and deformation of the structure can improve the quality of the project while ensuring the safety of the component. Secondly, during the construction, the sliding control of the dome steel truss structure should be carried out, and computer technology should be used to carry out synchronous construction control, and the hydraulic system should be used for reasonable processing. The reason is that the transmission acceleration of the relevant hydraulic system is relatively low, which can form a good control effect. , maintain the stability and safety of engineering construction, and facilitate operation work, so construction personnel can use the hydraulic system combined with computer technology to observe the entire process of slipping synchronously, use the man-machine interface to effectively operate, and combine manual and automatic control methods Integrate into it, use the electric operation method to process the hydraulic pusher, and adjust the specific construction status of the accumulated slip in real-time, so as to improve the construction effectiveness of the project.

For the dome, the lifting construction operation in the field of long-span buildings should accurately install the lifting machinery and equipment, and scientifically carry out the lifting test activities of the steel structure. After the test, if the standard is met, the lifting process can be formally carried out. It can also ensure the effectiveness of the lifting treatment of the dome steel structure, and provide a certain guarantee for the reasonable construction of large-span construction projects. First of all, in the work of installing the lifting equipment, after the completion of the steel structure assembly task, the overall lifting technical measures should be used. The tower structure uses a 2000kN oil cylinder, and the top part uses steel beams to effectively carry out the connection processing work. During the setting of the peripheral lifting points, the shell gusset plate is mainly welded to the lug plate. In the middle area, the corbel part is set on the ring beam, and then the lifting equipment is installed. Before installing the lifting steel strand part and the hydraulic cylinder part, measurement and analysis should be carried out on site. , the height of each lifting point must meet the requirements. During the specific installation process, the steel strand should be set in the upper and lower anchorage areas of the oil cylinder, and then fix the clamping plate. During this period, the hydraulic pump system and computer control system should be reasonably set up. During the installation of the hydraulic pump station, the hydraulic oil pipes should be connected according to the characteristics of the mechanical equipment, the hydraulic oil should be fully inspected, and the backup oil should be prepared. After the installation of the control system is completed, the overall hoisting system needs to be debugged to clarify the performance and various indicators, to understand whether the functions of the mechanical equipment meet the standards, and to ensure that the hoisting system can meet the specific hoisting requirements of large-span dome steel. Secondly, the lifting test of the steel structure should be focused on, and the lifting work should be carried out according to the site conditions. Immediate detectors should be installed in the support frame system and the dome structure to detect the specific stress conditions and strain data values of the steel structure, etc., and propose a lifting method. It is suggested that after the lifting test, if the standard is met, the lifting work can be officially carried out, and the installation and construction of the dome steel can be reasonably carried out to form a good construction application model in the field of long-span buildings.