+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

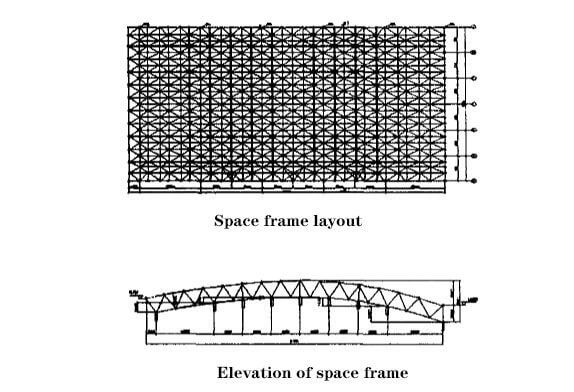

Figure 1 Basketball Stadium Steel Structure

China University of Geosciences Basketball Stadium is a comprehensive stadium with three floors above ground and one floor underground, with a building area of 16952m². The roof structure of the gymnasium is a steel structure with a peculiar shape, resembling a “bird head”. The steel space frame of the gymnasium is a regular square pyramid steel space frame, and the connection form is bolted ball connection. The east-west span of the roof space frame is 60m, and the north-south span is 47.6m. The elastic support is connected, the space frame of the steel space frame is a square with a side length of 4m, and all the rods are made of Q235B steel. Figure 2 shows the plan and front elevation layout of the space frame.

Figure 2 Basketball Stadium Space Frame

Analysis of basketball hall engineering characteristics and difficulties

(1) The construction environment is complex. The site is narrow, and the large-scale lifting equipment used to hoist the space frame does not have the installation conditions, which makes the construction more difficult.

(2) The construction period is tight. Due to the tight construction period and the winter construction period, the construction period of the steel space frame part is only about 50 days, and the construction needs to be carried out quickly and efficiently. (3) The space frame span is large. The steel space frame is in an arc shape, and the concrete columns have different elevations, making construction difficult.

Comparison and selection of steel space frame basketball stadium construction schemes

The commonly used methods for the construction of steel space frames in modern gymnasiums include a high-altitude sliding method, a high-altitude bulk method for full scaffolding, an overall lifting method, a block installation, a high-altitude docking method, an overall lifting method, and a high-altitude bulk method.

There are many difficulties encountered in the construction of the space frame project of the basketball hall. In order to ensure the progress, quality, and safety of the project, in line with the guidelines of economical, scientific, and reasonable, advanced technology and simple methods for the construction plan, the above-mentioned constructions were selected comprehensively. The advantages and disadvantages of the method, select the essence, removing the dross, and finally, this project adopts a new construction method – the high-altitude expansion assembly method.

The characteristics of this construction method are ① simple operation, wide applicability, and no need for large-scale construction machinery; ② less labor, scaffolding and other construction materials are required, which saves money and improves construction efficiency.

space frame construction technology

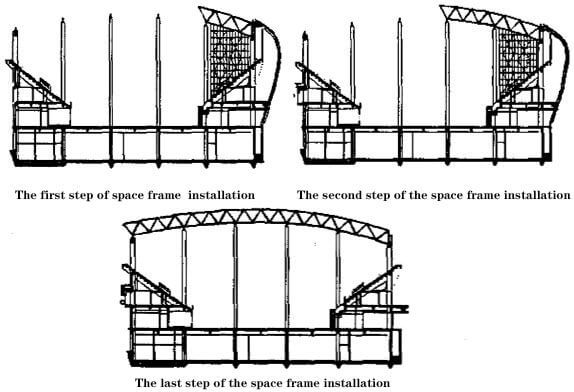

Figure 3 Space Frame Construction Steps

Step 1: In combination with the structural form and construction characteristics of this project, build a construction platform for assembling the space frame on the right stand of the basketball hall. The height of the construction platform should be 30cm lower than the lower chord point of the space frame. ), in order to ensure the accuracy and safety of the installation of the space frame construction platform, a leveling concrete cushion should be poured on the stands before erection. After assembling part of the space frame on the operation platform, it is connected and fastened to the support after checking. The effect diagram of the first part of the space frame is shown in Figure 3.

Step 2: On the basis of the assembled space frame, assemble from right to left, and hoist the small unit assembled on the ground to the operating platform on the support frame body. The small unit is based on a regular square pyramid. It is advisable to use a tower crane or a chain block to hoist the small unit into the air. The installer cuts the safety rope and sits at the node to find out the upper string ball hole and the lower string ball hole corresponding to the bar of the unit node, and quickly tightens the high-strength bolts between the bar and the ball in place, requiring the upper and lower bars to be connected with the bolt ball Work must be done concurrently. After assembling a unit node, move the spreader to another installation location, and repeat the above method until the installation of the entire axis space frame is completed. The effect diagram of the second part of the space frame is shown in Figure 3.

Step 3: Continue to install from right to left until the entire axis is installed. Do a good job of connecting with the support.