+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

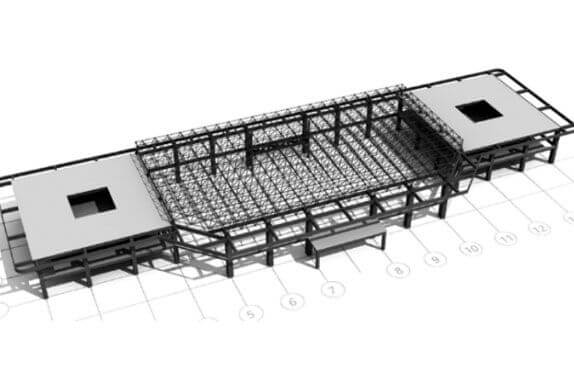

The new high-speed railway station steel structure building in Huidongnan Station is 144.0m long and 43.2m wide. The passenger building area is 7990.6m², the total building height is 17.15m (outdoor ground to roof cornice), and the number of floors is 1 above ground. (Part 2), Part 1 underground. The main body of the station building adopts a cast-in-place reinforced concrete frame structure. The basic column space frame size of the frame is 10.4m×11.2m. The roofs on both sides are made of concrete, and the embedded end of the upper structure is the foundation top surface and the partial basement roof. The steel roof of the waiting hall is 80m long and 43.2m wide. It is supported on the reinforced concrete column through the bottom chord bearing. The overall axonometric view of the station building is shown in Figure 1.

In the process of steel structure space frame construction, various technologies must be effectively applied. In the early stage, the corresponding construction units and construction personnel need to use the on-site splicing technology, optimize the roof construction technology, and improve the station building curtain wall construction technology. For effective improvement, the related technologies are analyzed below.

In the actual construction process of the new high-speed railway station building at Huidongnan Station, the application of steel structure space frame technology is relatively large, and the use of steel structure space frame on-site splicing technology has effectively improved the construction quality. In fact, due to the large workload of the station space frame as a whole, on-site welding is generally required. For the intersection of the truss and the sphere and the steel pipe, equal-strength butt welding is generally used. Fillet welds to improve the safety of construction work. For the weldment with the thickness of the pipe wall greater than 4mm, the interface needs to be treated as a groove. When assembling, the corresponding construction personnel should install it first, and then the lower chord will be installed. After that, the welding of steel pipes can be carried out. Since there are many influencing factors in actual weldings, such as welding heat input, welding method, welding seam cross-sectional area, etc., will cause certain obstacles to the welding operation. If it is not controlled, it will be lead to deformation problems. Therefore, the construction unit should reasonably use the on-site splicing technology of the steel structure space frame to reduce the influence of related factors and improve the overall level of construction operations.

In the process of the practical application of steel structure space frame roof construction technology, it is necessary to have a comprehensive grasp of the structure of the station building, and then comprehensively consider various environmental conditions in the actual construction process to ensure that other factors will not be affected during the construction process. influences. In the actual construction process, the corresponding construction personnel must master the technical points of the steel structure space frame roof construction and apply the steel structure slip technology. Save manpower to a certain extent, so as to ensure construction efficiency. At the same time, after the assembly work is completed, the corresponding construction unit also needs to carry out verification work, which is mainly for the internal force and mid-span deflection value of the rod. After obtaining accurate data, the corresponding construction personnel can determine according to the actual data. Sliding position, which can provide certain data support for subsequent construction operations, and can also largely ensure the safety of construction operations. In addition, in order to ensure the realization of the technical value of the steel structure space frame roof construction, the corresponding construction units and staff should also pay attention to the inspection of each link of the construction work during the actual operation process, reduce the influence of other factors, and ensure the space frame’s performance. Assembly quality.