+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

Airport Maintenance Hangar Construction

1. Project Overview

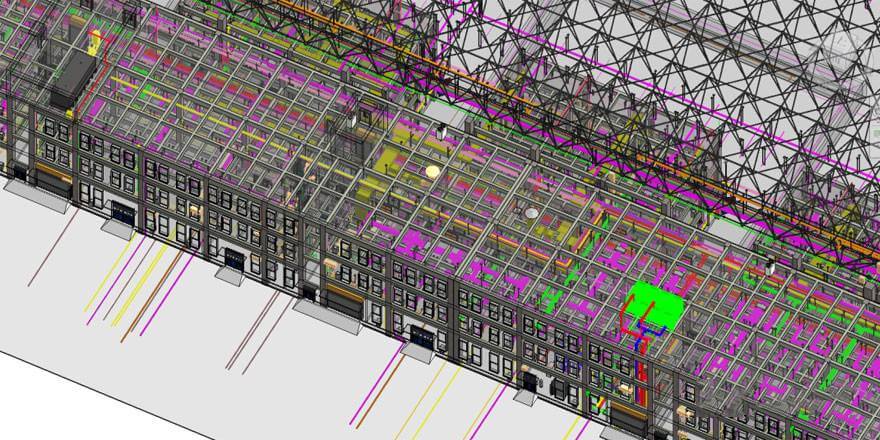

The project is divided into three phases with a total construction land area of 81,384.1 square meters. The construction land is about 336 meters long from east to west and about 227 meters wide from north to south (partially 108 meters). The new structures of the hangar project include the maintenance and painting of hangars and annexes, power stations, dangerous goods warehouses, waste warehouses, gatehouses, and outdoor works.

Rendering of the north side of the maintenance airplane hangar

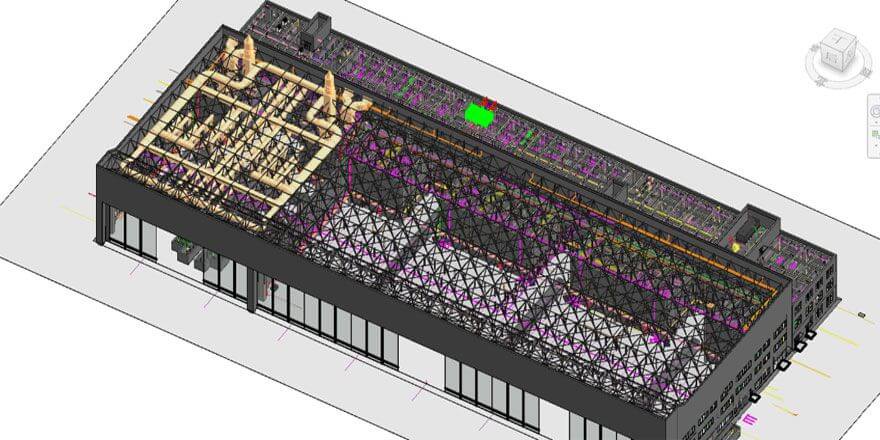

BIM comprehensive model of the maintenance hangar

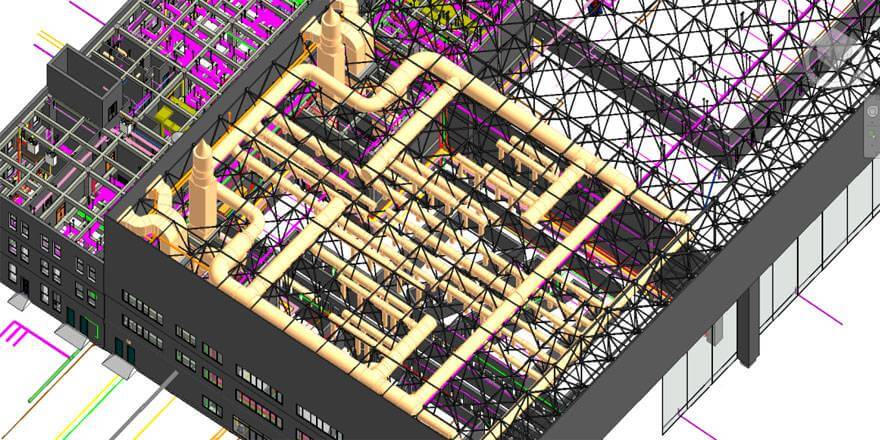

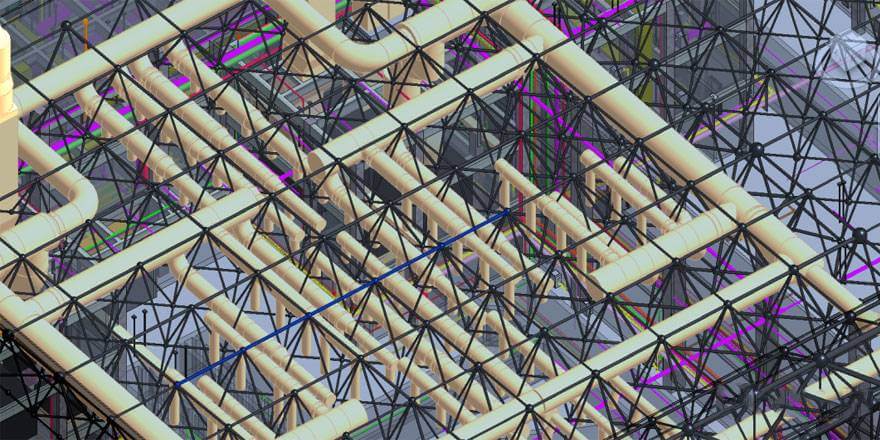

Air nodes above the aircraft painting hall in the maintenance hangar

2. International airport BIM model

In the picture above the aircraft painting hall of the maintenance aircraft hangar of the international airport, since the building span here is 123 meters, the roof adopts a two-layer oblique quadrangular pyramid space frame. The resulting problem is: there are relatively dense and large-sized air ducts in the air above the aircraft painting hall. How to ensure that the space frame will not collide with the ventilation system after the overall hoisting has become the problem that this project needs to solve. important question.

In the establishment of the BIM model, follow the principle of avoiding the large by using the small, making full use of the gaps in the space frame, and arranging the system with a large size first, and then arranging the system with a small size. Fully communicate and coordinate with structural designers and HVAC designers, integrate and eliminate unnecessary components as much as possible under the conditions allowed by the regulations, and finally achieve zero collision between the space frame and the ventilation system, and reduce the construction cost by 8%.

Prev: 105-meter-span roof space frame for the skating hall

Next: Raw Material Engineering Mixing Stockyard Warehouse Construction