+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

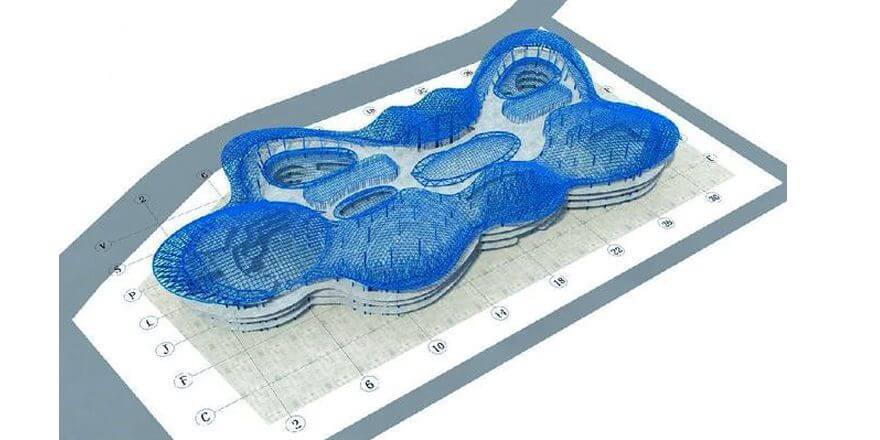

Haikou International Duty-Free City project commercial shopping mall roof space frame assembling and closing is completed. The space frame roof structure is nearly 8,300 tons, and the total steel volume is nearly 38,000 tons, which is comparable to the steel consumption of the National Gymnasium’s “Bird’s Nest”. Perfectly presents the whole picture of the space frame design of “Auspicious Clouds in Kyushu”.

1、Professional design practical assembly foundation

The roof shape is a hyperbolic structure, and the space frame nodes include more than 30,000-rod members and more than 10,000 drum members, and each steel structure drum node is almost different, and the design workload is huge.

The steel structure construction project team, the head of structural design, the welding engineer, and the processing plant discussed, studied, and analyzed the feasibility and rationality of different processing and installation schemes many times, and successively completed 17 batches of deepening drawings in different regions to ensure that the stress of the construction node met the design requirements and ensured the perfect appearance of the design of “Jiuzhou Xiangyun”.

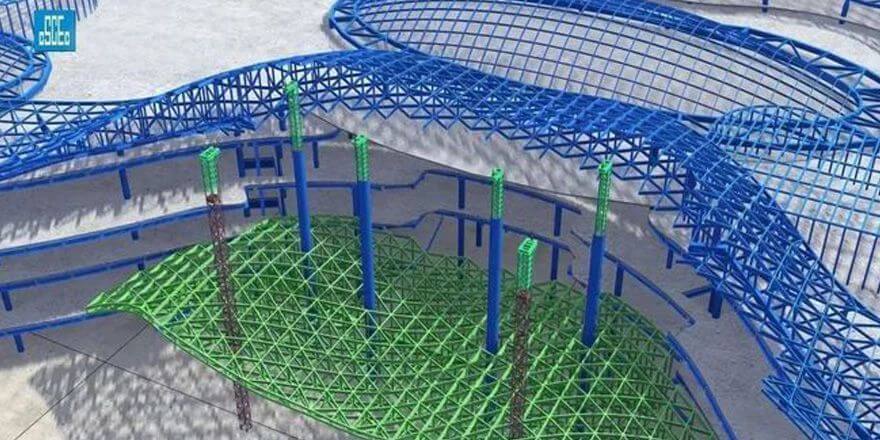

2. Intelligent lifting ensures the climbing of the space fame

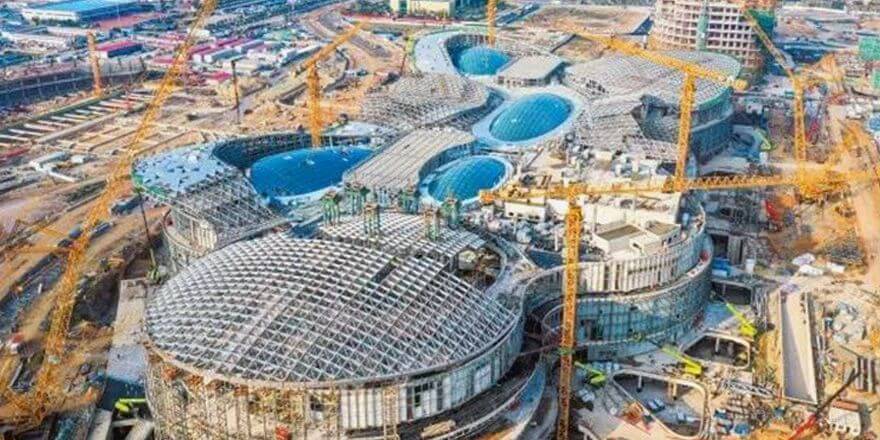

In the Haikou International shopping mall project, the roof space frame structure is heavy. The project considers the characteristics of the space frame, hoisting equipment, structural stress, and other factors, and adopts the steel structure construction technology of “segmented hoisting + overall lifting”. The roof reticulated shell is 350 meters long from north to south and 180 meters wide from east to west. The outer structure adopts a combination of a single-layer reticulated shell and a double-layer reticulated shell. It is divided into 8 construction areas and a total of 150 hoisting blocks for construction. The weight of each hoisting block is About 20-40 tons, all assembled by rods and drum nodes on the ground, and finally lifted and installed by two 500T crawler cranes.

The hoisting of the space frame on the top of the main entrance on the west side and the space frame on the top of the tropical rain forest is the most difficult part of the closing of the main body. It is a huge challenge for the project team to lift the steel structure space frame with a total weight of about 1,000 tons to a height of 40 meters. challenge. After many discussions, the project team adopted the “Internet +” overall lifting scheme and controlled the lifting equipment through the computer-controlled synchronous lifting system. The construction process is smooth and efficient.

3. The fine operation ensures dome closure

In order to ensure the smooth operation of the dome hoisting of the shopping center, a 500-ton crawler crane was used, four hoisting points were set, and a leveling device was added at the same time to control the installation deviation of the grid hoisting unit within 5 mm. By balancing the force between the hoisting points, the resultant force ensures that the components are accurately and stably placed in place, the hoisting accuracy is always maintained at the millimeter level, and the space frame roof is successfully hoisted into place.

Prev: Steel Structure Air Exhibition hall

Next: Welded Ball Space Frame Structure Aircraft Hangar Project