+86 177 5193 6871

222, Block B, Diamond International, Guozhuang Road, Xuzhou, Jiangsu, China

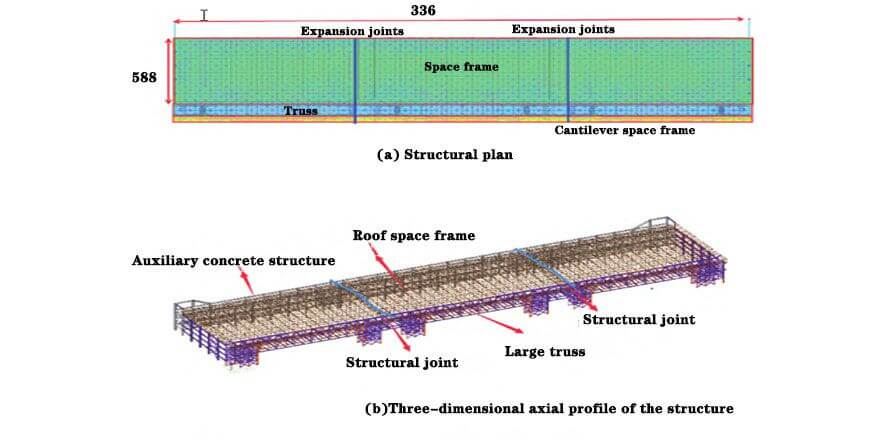

The total construction area of the steel hall is about 40,000 square meters. The plane size is 336m×80m, and the highest height is 28.8m. The steel exhibition hall is a medium-sized exhibition building, and the exhibition hall is divided into grades B according to the exhibition area.

The steel Air Exhibition Hall is used as a parking hangar on weekdays. According to the use requirements, it can meet the requirements of 6 side-by-side parking and 9 cross-parking of B737-800 Type C aircraft. The hangar door is directly above the VIP hall, there is a load. The roof of the light steel structure hall has a novel shape, regular column position, and visible roof structure. Combining with the architectural characteristics of the project, a structural form of beautiful architecture and reasonable stress is optimized, namely, the combined system of space four-angle cone space frame+ truss. The structure of the exhibition hall is divided into an auxiliary concrete structure, a huge entrance truss, es, and a steel roof. The total length of the roof is 336m, divided into two structural joints, and the structural length of each sub-block is 106,124,106m respectively (FIG. 2 ).

FIG. 2 steel hall

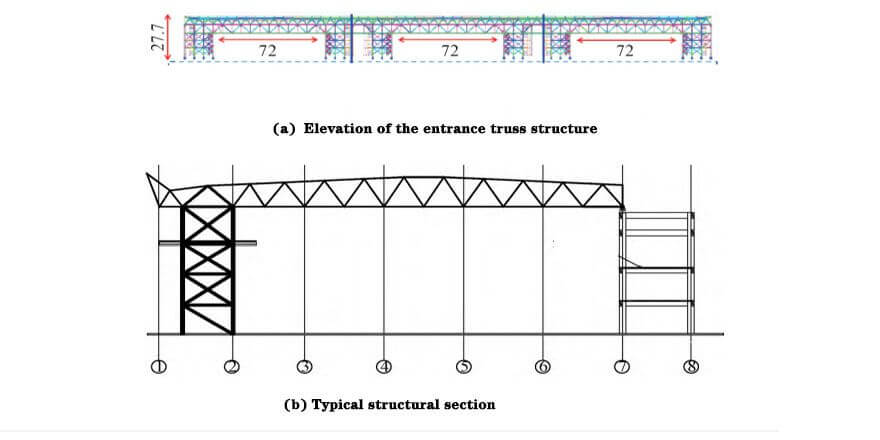

The auxiliary concrete structure has four floors above ground and the roof elevation is 21.000m. The entrance truss is located directly above the hangar door with a span of 72m, and each substructure is supported by two giant truss columns (Figure 3). The roof space frame spans 58.8m. One side is supported by the concrete structure roof of the auxiliary house, and the other side is connected with a giant truss beam. The gable part is supported by steel columns (FIG. 3). The highest elevation of the roof structure is 27.700m.

FIG. 3 steel truss structure

Combined with the mechanical characteristics of the engineering structure, the strict construction period, and the location requirements of the project, the truss and space frame adopt the construction technology of “ground partition assembling, partition lifting, and high altitude filling”. After the roof space frame structure is assembled as a whole on the ground, the “hydraulic synchronous lifting technology of super large components” is used to lift it two times:1) Only the space frame part is lifted from the ground to 6.000m elevation, and is connected with the truss part by embedding; 2) Lift the truss and space frame to the roof elevation as a whole after completion of the embedding.

Prev: The steel structure roof of the sport stadium was capped

Next: Prefabricated Space Frame Roof Commercial Shopping Centre